double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

double wall corrugated pipe production line, high speed big diameter plastic pe pipe product line

| Features of plastic pe pipe product line |

1) Optimizing diameter range of pipe production, can produce bigger diameter range with same investment. 2) Smooth and stable operating water cooling system, ensure high speed production. 3) Can replace mould block quickly, to save waiting time. 4) Most intelligent control on water, air pressure and electricity, easy to operation, monitoring and control. 5) Die head with partial wall adjustment function, convenient and easy to operate. 6) Corrugator section with quickly open function, greatly convenient to trouble shooting, equipment maintenance and other operations. 7) Multistage vacuum molding system, easy to forming, stable operation. 8) Central lubrication system. 9) Remote fault diagnosis system (Optional). |

| Factory of plastic pe pipe product line |

1) Engaging in innovating new technology, devoted to research and develop new technology on plastic machinery for decades of years. 2) Combining the world most advanced technology and new material. 3) Excellent skilled workers, especially R&D engineers, technicians with decades of experience in this industry. 4) First-class after sale service, with the most competitive price. |

| Applications of Double Wall Corrugated Pipe |

1) Cable protection pipes 2) Drainage pipes 3) Other special pipes |

| Suitable Material of plastic pe pipe product line |

HDPE, PP, PVC and other polymers |

| Corrugator Section Specification of plastic pe pipe product line | ||||||||||||||||||||||||||||||||||||||||

|

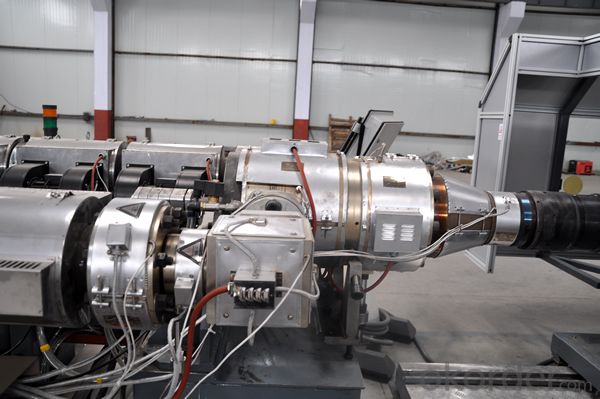

| Detail pictures of plastic pe pipe product line |

Automatic feeder with self-dry function, space saving and efficient. Long effective screw, excellent melting effect.

Shorter die head, low pressure, low temperature, high efficient (patent).

Die head with partial wall adjustable function, convenient and easy to control.

Corrugator with cover, safe. Also with quick open function, great convenient for trouble shooting, maintenance and other operations.

Aviation aluminum mould blocks, very durable and long service life.

Horizontal water cooling system, high efficient and time saving.

Dustless double hydraulic cutter

Automatic unloading device.

Intelligent control on water, air pressure and electricity, easy to operate. Comprehensive protect for all kinds of wire, safe and durable. Touch screen with wireless control handle, very safe and convenient for operating. |

| Samples made by plastic pe pipe product line |

|

- Q: Which kind of engineering plastics can be machined on machine tools?

- General raw materials market is available, you can also contact the internet.

- Q: Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q: Such as title, small items, but also the size of the palm, and want to mass production, plastic, production machinery, abrasives about how much money, the smallest sizeIn addition, the production of plastic products are not required sewage ah, online and other great god!!

- There are thousands of plastic, you first understand some commonly used bar, usually ABS, C material, B material. There are floating water and submerged, and so on. There are 4 kinds of plastic on a mineral water bottle, do you know?

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Plastic products factory work on the human body will be a number of pollution, direct pollution, there are indirect pollution, but still depends on what material and what post.Plastic products generally include plastic batching, molding, machining, bonding, finishing and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Plastics burn easily and produce poisonous gases when they burn. For example, toluene combustion produces a small amount of polystyrene, this substance can cause blindness, vomiting and other symptoms of inhalation, PVC combustion will produce toxic gases, hydrogen chloride in combustion, is a high temperature environment, will lead to plastic decomposition of toxic components, such as benzene etc..In December 31, 2007, the general office of the State Council issued a notice on limiting the production, sale and use of plastic shopping bags, which was called "plastic restriction order" by the masses". The reason is that plastic shopping bags, while providing convenience to consumers, have caused serious waste of energy, resources and environmental pollution due to excessive use and recycling. As we all know, coupled with the large volume of waste plastic foam, garbage recycling channels are not smooth and other reasons, the pollution problems can not be underestimated. But because of the low cost of plastic foam and easy to use, some well-known online shopping shops still continue to use.

- Q: Plastic machinery plastic pellet production process _ particles recycled plastics particles

- 16 、 domestic garbage plastic particle flotation device17 、 granular plastics dehumidification drying system18. Methods for the preparation of colored plastics or colored polymeric particles19. A method for producing a particulate formulation that is soluble in a plastic stain20. The spherical particles are prepared by the plastic melt21. Lactam based pigments and their use in the production of colored plastics or polymeric colored particles22. Methods for producing colored plastics or polymeric colored particles23, columnar particles of plastic compound additive, production process and application thereof24, manufacturing method of waste plastic particles and thermal decomposition method thereof25. The preparation of colored plastic or polymer dye granules26. Azo dyes, their preparation methods and their applications in the manufacture of colored plastics or polymers, colouring particles, and dyeing or printing of hydrophobic fiber materials27, pyridine ketone dye, process for the preparation thereof, and use in the manufacture of colored plastic or polymer colored particles28, pyridine ketone dye, process for the preparation thereof, and use thereof in the preparation of colored plastics or polymeric colorant particles29. Coating compositions of thermoplastic resin particles for forming foam containers30. Adsorption dryer for plastic material particles

- Q: What plastic products are made out of machines? Is it an injection molding machine?

- According to the process, there are many kinds of processing equipment, not only the injection molding machine, as well as extruder.

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: What kind of equipment do you need for plastic basin processing? How much is it?

- Injection molding machine manufacturers are different, the degree of automation is different, the price is different, two injection molding machine about five hundred thousand yuan.

- Q: What sewage treatment equipment should be used for waste plastics processing granules?

- Don't be cheap. Environmental protection will only get tighterAfter three months, the water is out of balance

Send your message to us

double wall corrugated pipe production line high speed big diameter plastic pe pipe product line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords