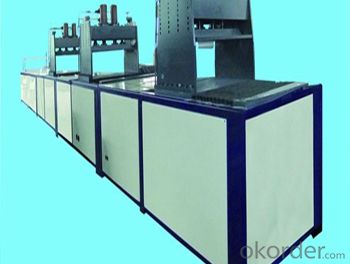

FRP pultrusion machine and strengthen profile making equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP pultrusion machine and strengthen profile making equipment

Product Description:

We manufacturer kinds of FRP filament winding machines for different usage, the following include:

1.FRP drain pipe/marine pipe production line

2.FRP tube continuous production line

3.FRP storage tank production line

4.FRP cable protection production line

5.FRP heat insulating tube production line

6.FRP oil pipe/high pressure/low pressure pipe production line

7.FRP vertical tank production line

Product Features:

1.The main machine is steel structure, stainless steel panel, side panel is paint. With the two kinds of pultrusion modes:Debugging and succession, it is convenience to adjust the production craft;

2.Traction gantry makes ordered according to requested length.

3.The machine had two hydraulic pressure system, it had strong ability of anti-interference;

4.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically settled, and the actual production tension can be feedback by sensor.

Product Parameter:

Name | FRP pultrusion machine and strengthen profile making equipment |

Brand | CMAX |

Weight | 3-15T |

Dimension(L*W*H) | 4100mm*1550mm*1460mm |

Power | 90KW |

Voltage | 380V 50HZ 3Phase(Customized) |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customizable |

Warranty | 1Year |

Time of Delivery | 30-45 days |

Product Show:

- Q: Types of plastic machinery

- Characteristics of injection molding machine control system:1. 、 adopt advanced computer control of famous factory;2. self diagnostic fault function;3. direct input pressure, speed, time, travel and temperature data;4.LCD color liquid crystal display (pictured below);5. centralized lubrication;6. pressure coupling circuit saves power;7.24 V DC oil pressure directional valve coil never damaged;8. die cooling water regulator;9.M.C.B. insurance electrothermal control;10. advanced computer control system, large screen display, operation interface, easy to use cylinder;11. high-precision electronic ruler stroke control, accuracy up to + 0.1mm;12. improve reproducibility by using pressure and oil feedback;13. mechanical, electrical, hydraulic 3 heavy safety devices, in any case can ensure the safety of the operator (PD60-PD148 matching oil pressure);14. improve the reproducibility and operability by installing superior position sensors;15. using closed-loop control to achieve ultra precision forming.

- Q: How can rubber products be machined?

- The types of mechanical processing of plastic products, mainly cutting, punching, cutting, drilling, thread processing, laser processing, etc..

- Q: Method for producing plastic product

- The plastic processing method can be used for rubber processing. In addition, there are liquid monomers or polymers as raw materials such as casting. In these methods, extrusion and injection molding are the most widely used and the most basic molding methods. The mechanical processing of plastic products borrows plastic processing methods such as metal and wood, and makes plastic products of very accurate size or small quantity, and can also be used as the auxiliary process of forming, such as the sawing of extrusion sections. Because the plastic properties and different thermal conductivity of metal and wood, plastics, thermal expansion coefficient, low elastic modulus, when the fixture or tool pressure is too large, easy to cause deformation, cutting heat melting, and easy adhesion on the cutter. Therefore, the plastic processing, the tools used and the corresponding cutting speed, etc., should be adapted to plastic characteristics. The commonly used mechanical processing methods are sawing, cutting, punching, driving, planing, drilling, grinding, polishing, thread processing and so on. In addition, the plastic can also be used laser cutting, punching and welding.

- Q: My home is the county seat, want to open a waste plastic recycling, and then processed into plastic particles factory, do not know how the market? If there is cooperation between manufacturers, the best production, processing can also be.

- If you don't know where your friends are, the coastal areas are the ones that sell well and the rest is not the problem. Inside the road area on the raw materials, you can not get rid of the market competition, brother did not coast?. Start doing general Kazakhstan, is to do PP, PE and other general plastic raw materials, use more widely, but profits must be low. Engineering plastics use limitations, raw materials are not so good, technical requirements are also high. Such as PC, PMMA and so on, 1-2 tons in case of no technical careless, really made waste!

- Q: Such as "computer embroidery processes" - Programming - sample preparation, shipment packing production computer

- Process flow of plastic products1. Preparation before moldingA, grain preheating and drying: if the grain is affected with damp, it should be dried;B, insert preheating: in order to reduce the gap between the cooling shrinkage value of metal and plastic, the larger metal insert should be preheated.C, barrel cleaning: when changing the product, changing the raw materials, cleaning cylinder is required.2, injection molding process feeding - plasticizing - injection - holding pressure - cooling - die opening piecesA, feeding: each feeding should be quantitative, in order to ensure uniform plasticization;B and plasticization: the grains are heated to a molten state in a barrel;C and injection: the injection molding machine uses a screw to inject molten plastic into the mold cavity;D, keep pressure: after the mold is finished, maintain the pressure for a certain time;E and cooling: keep cool for a certain time in the mold cavity;F, mold opening parts: mold open, take out the product.3, plastic parts after treatment: plastic parts after treatment:A, remove the fly edge, material handle.B, inspection and packing.

- Q: How are the plastic products made of this texture processed?

- Plastics processing technologyPlastic forming process. It is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a larger manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Mixed ingredientsPlastic processing of raw materials, in addition to the polymer, usually also added a variety of plastic additives (such as stabilizer, plasticizer, lubricant, coloring agent, reinforcing agent and filler etc.), to improve the performance of molding process and product or reduce the cost of products. The additive and the polymer are mixed and evenly dispersed into powder, also called dry mixed material. Sometimes, the powder is also processed into pellets. The powders and pellets are referred to as synthetic or moulded plastics.

- Q: Why is the dimensional accuracy of molded plastic parts much lower than the accuracy of machined products?

- Therefore, the precision of plastic products is lower than that of machined products by 1~2 grades.

- Q: What's the pollution of plastic processing to environmental protection?

- From the ground floor to the surface, to the living to the sky, it is a full range of pollution!

- Q: How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

FRP pultrusion machine and strengthen profile making equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches