Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

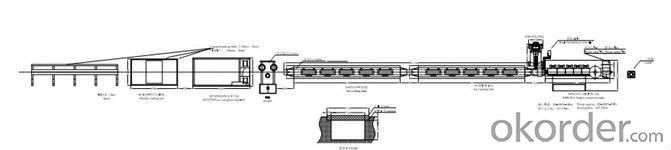

This production line adopts unique design, seperated BM type high efficiency screw, high degree of automation, convenient operation, continuous production, it is stable and reliable. The production of plastic pipe, has the characteristic of heat resistance aging resistance environmental stress crack resistance,cracking resistance,creep resistance, is the first choice of product of inter-city gas pipeline.

This product can also produce large-diameter PE water supply pipes, and the pipes is non-toxic, tasteless, no corrosion, anti-ageing, weatherability and so on many good characteristics, such as can be widely used in not more than 45 degrees of water supply pipe buried or surface, replacing zinc-plated steel, cast iron pipe, tube of cement ideal products.

Drawing upon profuse experience in this field, we have innovatively manufactured a number of state-of-the-art machines which enables our customers to pursue the most while keeping a possibly lowest cost. The Plastic Pipe Extrusion Line from FAR EAST(CHINA) can use a variety of polymers such as PE, PP, PVC to produce a broad range of plastic pipes with solid quality.

Main Configuration of large caliber Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

Specification of typical single screw extrusion lines

|

- Q: What are the plastic products used in heavy trucks, and how do they form?

- 5 、 blow molding, blow molding, used in thermoplastics. This is the molten plastic in the mold, under the compressed air pressure, the plastic blow up, close to the mold surface. But, by punching and demoulding products. The production of various types of hollow containers, also can produce thin film, and thin. The land, forming a plurality of heating heating molding thermoplastic. This is the plastic sheet is heated into elastic state, and then subjected to pressure to attach to the mold molding. Multi disc products. Production of dishware, paint, plastic foam molding foaming foot add foaming agent, foaming and foam injection mould making, solidifying products. The utility model is used for making cushioning packages for precise instruments and meters. It is used for molding, molding the thermosetting plastic. This is a powder, flake or granular thermosetting resins and additives, directly close mold in mold, heating, pressurizing, plastic and liquefaction, chemical reaction and curing, cooling after the products. Production of lumber and electrical appliances, machinery parts, 9, casting molding casting molding for jade. The thermosetting plastic molding powder is placed in the material barrel heating to heat plasticizing, pressed into the mold, and the product complete solidification under pressure. Complex products production needs. A metal block 0, casting casting for forming solid thermal plastic. It will plasticized thermosetting plastic injection mould, curing under normal pressure, cooling and demoulding to obtain the products. The production of electronic, electrical and metal insert element

- Q: Processing method of PPS plastic

- For housing, structural parts, wear parts and sealing materials, such as: concrete pump casing, pump, valve, bearing, bearing bracket, piston ring and gear, pulley, fan, meter parts, flanges, Wan Xiangtou, counter, leveling. 2, electronic and electrical appliances: PPS for electronic and electrical appliances industry accounted for 30%, it is suitable for high temperature electrical components in the environment temperature higher than 200 DEG C; manufacturing generator and engine point rinse, rinse the electric coil, starter bracket, shield and leaf; on the TV, it can be used for high voltage shell and socket, wiring column and terminal plate; and a relay coil in the electronics industry, manufacturing transformers, resistance of the skeleton and shell, an integrated circuit carrier; using high frequency performance, manufacturing H bobbin and capacitor etc.. Micro electronic components, connectors, connector, socket, coil skeleton, Ma Dake, electromagnetic regulating plate, TV tuner shaft, relay, trimming capacitor, fuse holder, tape recorder, magnetic device and other components. Also used in precision instruments: computers, timers, speed machines, copiers, cameras, temperature sensors, and all kinds of measuring instruments shell and parts.

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: What are the processes and machines used in the manufacture of plastic products?,

- In recent years, the proportion of plastic products is increasing rapidly in many fields, such as household appliances, instruments and meters, building materials, automobile industry, daily hardware and so on. The requirement of high precision and high performance of plastic products increases with each passing day, which makes the precision forming technology progress constantly. Injection molding is one of the most important plastic forming methods, and many factors affect the precision injection molding. 1. in the early stage of the design of plastic products, injection molding materials should be selected according to their application environment. 2. precision molds, rational design of precision injection mold is the basis and necessary prerequisite for precision products. Precision molds are indispensable to produce precision products. The precision of the die is usually affected by the temperature control of the die, the precise manufacture of the die and the choice of the plastic shrinkage when the die is designed. 2.1 control of the mold temperature due to the effect of mold temperature on shrinkage molding, but also directly affects the mechanical properties of plastic products, can also cause various defects of product surface flooding, so must keep mold in the specified temperature range, but also to make the mold temperature changes over time. In the injection molding of general precision parts, the temperature of the die is controlled mainly to increase productivity. But the impact of temperature control of mold for injection molding is great, it affects parts of the shrinkage, shape, crystallization, internal stress, so the design of mold hot loop temperature distribution at the request reasonable precise control accuracy, the best use of mold temperature machine and cold water machine control.

- Q: Which kind of engineering plastics has good processability?It requires small deformation and high machining accuracy when subjected to force

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: PC and PC alloy plastic surface effect which better, which good processing, and what are the other differences?

- The plastic processing of PC alloy PC alloy, in order to improve the mechanical properties of other plastics and the incorporation of PC raw materials, such as PC/ABS, PC/PA, PC/PS and so on, area is PC as a reinforcing agent with other plastics.

- Q: I would like to open a small plastic daily necessities processing factory, want to buy such as plastic buckets, plastic basins, plastic small bowl machinery!

- Similar processing machinery, you can go to the machine processing and other similar websites to check

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: What kind of equipment does the plastic product factory need?

- The current plastic, if the raw materials and semi-finished products are relatively low profits, it is recommended to do directly in the above color printing, the added value of high. Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q: What mechanical products do you use to make this plastic product?! The more detailed, the better!

- I'm not sure about the mold design. You can find a device and ask for advice. Generally, they will be responsible for design and training

Send your message to us

Supply Hot sale china PVC PPR PE plastic pipe production line(extrusion line/extruder machine/making machinery)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords