Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

1. AUTOMATIC FEEDING SYSTERM

2. ABB BRAND INVERTER

3. RKC BRAND TEMPERATURE CONTROLLER

PE PIPE PRODUCTION LINE EQUIPMENTS FEATURES:

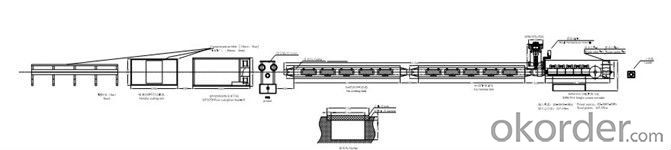

PE pipe production line qingdao benice plastic machinery co.,ltd mainly consists of PE single screw extruder, PE pipe special using mould, PE pipe vacuum calibration water tank, PE pipe drawing machine, PE pipe cutting machine, PE pipe stacker, and the auxiliary machine: SHL200/500 mixer.

PE pipe plastic making machine features:

High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialized screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket die head, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely. Skype is benicexiaofei

Plastic PE pipe making machine specifications:

Model | Pipe diameter Range (mm) | Pipe extruder model | Marking- line extruder model | Extrusion speed | Max Output | Total installed power | Dimension |

BAXPEG-50×33-63 | Ø20-Ø63 | BAXSJ-50×33 | BAXSJ-25×25 | 0.3-12 | 120 | 65 | 36 ×2.2 ×2.5 |

BAXPEG-65×33-125 | Ø20-Ø125 | BAXSJ-65×33 | BAXSJ-25×25 | 0.3-12 | 220 | 110 | 56 ×2.2 ×2.6 |

BAXPEG-80×33-160 | Ø63-Ø160 | BAXSJ-65×33 | BAXSJ-30×25 | 0.3-6 | 300 | 150 | 50×2.2 ×2.8 |

BAXPEG-80×33-250 | Ø75-Ø250 | BAXSJ-80×33 | BAXSJ-30×25 | 0.5-5 | 400 | 200 | 52 ×2.2 ×3.0 |

BAXPEG-90×33-400 | Ø160-Ø400 | BAXSJ-90×33 | BAXSJ-30×25 | 0.2-2 | 550 | 280 | 66 ×2.2 ×3.0 |

BAXPEG-90×33-500 | Ø200-Ø500 | BAXSJ-90×33 | BAXSJ-30×25 | 0.1-1 | 700 | 360 | 70 ×2.3 ×3.5 |

BAXPEG-120×33-630 | Ø355-Ø630 | BAXSJ-10×33 | BAXSJ-30×25 | 0.1-1 | 900 | 450 | 72 ×2.3 ×3.5 |

BAXPEG-150×33-1200 | Ø710-Ø1200 | BAXSJ-150×33 | BAXSJ-45×30 | 0.05-0.5 | 1500 | 650 | 80 ×3.0 ×4.0 |

Main Configuration of Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

- Q: What are the requirements of customers for nylon plastic products?

- Nylon engineering plastics products as the largest and most important varieties, has very strong vitality, mainly because it is modified to achieve high performance, followed by cars, electrical appliances, communications, electronics, machinery and other industries of high performance products are more strongly. The rapid development of related industries, promote high performance engineering the process of plastic, nylon future development trend are as follows.

- Q: Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: How much profit can a ton earn? Is it difficult to operate the program?

- This machine is mainly used for classification, after crushing, washing, dewatering and drying of PET sheet for processing our company successfully developed a new generation of "PET bottle recycling unit, this machine adopts fully closed, the whole production process without spray, no noise, waste bottle with PET as raw material. With high yield: SJL150 type can produce about 400 kilograms per hour, the product quality is good: the particles are white, transparent, good color, low energy consumption.Selection process: coke bottle, oil bottle, mineral water bottles and other various beverage bottles and etc.. 1. the outside trademark tear, these trademarks are mostly PVC, namely PVC shrink film 2. second were crushed, began to shatter the heart must bring water flushing to some other 3. other third step of removing sludge washed 4. refractory impurities fourth steps and then washed with water to the dryer to dry the water bag 5. (ball) into the vacuum oven drying 6. spinneret, setting 7. hot water steam shift extension, setting 8. wire into the packaging machine packing label factory after weighing 9.

- Q: Environmental impact of foam plastics reprocessing

- Landfill operation is still one of the main methods for municipal solid waste treatment in our country. Because the plastic film of low density, large volume, it can quickly fill up space and reduce landfill site waste disposal capacity; and, after the landfill site because the ground is soft, bacteria, viruses and other harmful substances in the waste is easy to seep into the ground, groundwater pollution, endanger the surrounding environment.If the waste plastics are burned directly, it will cause serious two pollution to the environment. Plastics burn not only a great deal of black smoke, but also dioxin, the most toxic substance to date. Dioxins enter the soil for at least 15 months to decompose gradually. They can damage plants and crops. Dioxins can cause severe damage to the liver and brain of animals. The environmental pollution of dioxin emitted from waste incineration has become a very sensitive issue all over the world.

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Hello, the county bag if shipped from the field, the local should not do bags, it is a market.The machine used in plastic packaging food bags is film blowing machine and bag making machine. If you print words and patterns, add a printer. The price is not the same from more than 60000 to hundreds of thousands of different.

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- You send the amount of plastic parts should refer to the use of injection molding mold design, injection molding parts need to know the relevant knowledge of mold structure, mold design or you out of difficult processing, or even can be processed but need to increase the cost a lot of plastic design with rubbing wear and broken, less inclined to top. That will increase the cost of.

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- First you need to recover some of the waste plastics, and then processing the plastic grain, in this process, you will also find a good sales channels, you can find some plastic products factory, plastic grain demand to talk about things and they are. You need to buy some advanced machines for processing plastic particles, so as to ensure the quality of the plastic particles.

- Q: Where has the machine which sells the plastic processing, wants the true, begs the answer

- Jiangsu and Zhejiang provinces are many (New), Heilongjiang has many families also to buy (old).

- Q: What chemicals should be used in plastic products?

- Several commonly used plastic additivesPlastic additives can be divided into seven categories according to their specific functions: additives for improving processability, such as thermal stabilityA constant agent, lubricant, etc. Additives for improving mechanical properties, such as plasticizers, toughening agents, etc.. The changeAdditives for good surface properties, such as antistatic agents, coupling agents, etc.. Additives to improve optical properties, such asColorant, etc.. Additives to improve aging properties, such as antioxidants, light stabilizers, etc.. The reduction of plasticAn additive such as an extender, a filler, etc.. The specific effect of giving other additives such as foaming agent,Flame retardant and anti mildew agent etc..Additives are meant to be dispersed in the plastic molecular structure without serious impactA chemical structure of plastics that improves its properties or reduces its cost. Addition of additives, energyThe plastic can improve the processing, physical and chemical functions of the base material and increase the physics and chemistry of the base materialCharacteristic。

- Q: Hello, small plastic processing plants need what equipment, how much the price, how to process, the size of the site, thank you

- The project is very good. I want to do it very much. This machine goes there to buy it,

Send your message to us

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches