Interior Wall Cladding Systems

Interior Wall Cladding Systems Related Searches

Internal Wall Cladding Systems Exterior Wall Cladding South Africa Black Metal Cladding Acrylic Cladding Panels Indoor Window Insulation Indoor Window Insulator Interior Composite Doors Indoor Spotlight Fixture Black Indoor Wall Lights Indoor Insulation Acoustic Padding For Walls Decorative Interior Doors Best Wall Insulation Inline Drip Irrigation System Stairway Lighting Indoor Concrete Faced Insulated Wall Panels Indoor Plantation Shutters Exterior Textured Wall Coatings Commercial Lights Indoor Insulating Paint Indoor Lights For Houses Texture Coating Exterior Walls Loft Insulation Flat Roof Systems Decorative Lights Indoor Concert Lighting Systems Insulation Slabs Roof Insulation Materials Indoor Window Ceramic Sheet InsulationInterior Wall Cladding Systems Supplier & Manufacturer from China

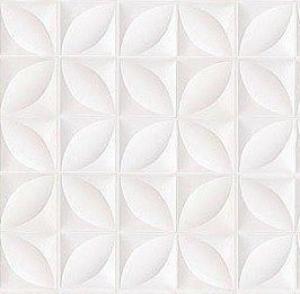

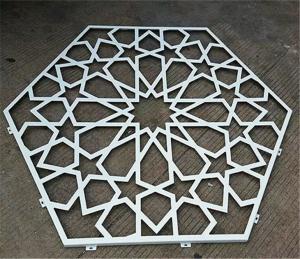

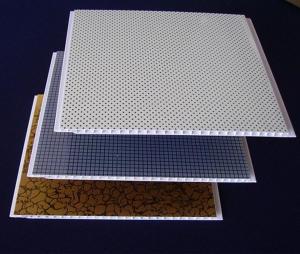

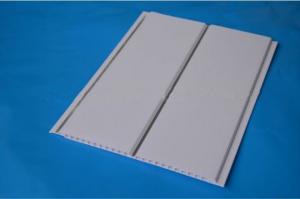

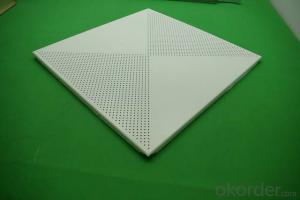

Interior Wall Cladding Systems are a popular choice for enhancing the aesthetic appeal and durability of indoor spaces. These systems consist of various materials such as wood, metal, and plastic, which are designed to cover and protect interior walls from damage while providing a visually appealing finish. They are an excellent option for both residential and commercial settings, offering a wide range of design possibilities and customization options to suit individual preferences.Interior Wall Cladding Systems are widely used in various settings such as homes, offices, hotels, and public buildings. They are particularly beneficial in areas prone to moisture, as they protect walls from water damage and mold growth. Additionally, these systems are easy to clean and maintain, making them an ideal choice for high-traffic areas. They can also be used to create a unique and stylish ambiance, with a variety of textures, colors, and patterns available to choose from.

Okorder.com is a reputable wholesale supplier of Interior Wall Cladding Systems, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com ensures that their products meet the highest industry standards and are available for quick shipping worldwide. Whether you are a contractor, architect, or homeowner, Okorder.com is your one-stop-shop for all your interior wall cladding needs.

Hot Products