Fireproof glass windows and doors((Borosilicate Float glass 4.0)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Borosilicate glass is a kind of high content of borosilicate. Borosilicate 4.0 fireproof glass is named by its expansion coefficient of 4.0 ± 0.1 × 10-6/K. Glass is required to have excellent stability when used as a fireproof glass windows and doors.The fire resistance stability of this glass is currently the best among all fireproof glass, and the stable fire resistance duration can reach 120 min (E120).

Moreover, borosilicate glass also has high transmittance at high temperatures.This function is critical in case of fire and poor visibility. It can save lives when evacuating from buildings. High light transmittance and excellent color reproduction mean that it can still look beautiful and fashionable while ensuring safety.

Advantages:

• Fire protection duration exceeding 2 hours

• Excellent ability at thermal shack

• Higher softening point

• Without self-explosion

• Perfect in visual effect

Application scene:

More and more countries require doors and windows in high-rise buildings to have fire protection functions to prevent people from being too late to evacuate in the event of a fire.

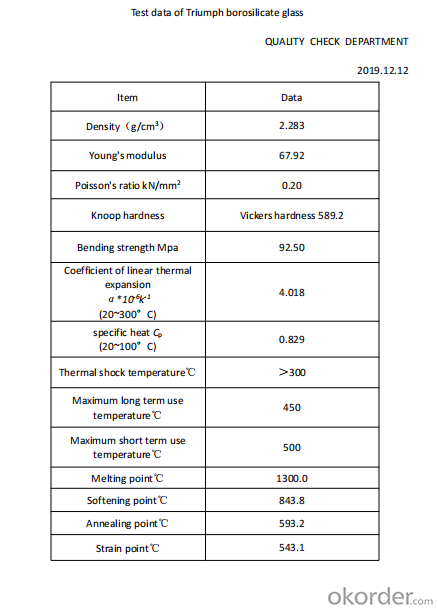

Actual measured parameters of triumph borosilicate glass (for reference)

Thickness Processing

The thickness of the glass ranges from 4.0mm to 12mm, and the maximum size can reach 4800mm×2440mm(The biggest size in the world).

The biggest size in the world:4800mm×2440mm

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Company introduction

Founded in 1922,China Yaohua Glass Group Co.,Ltd.(hereinafter referred to as "Yaohua Group") is a second-tier subsidiary of Triumph Science&Technology Co.,Ltd..It is the first manufacturer in Asia to continuously produce flat glass by machine,and is known as “the cradle of Chinese glass industy”.

Yaohua Group, as the core platform of Triumph Science & Technology Group for high-quality float and special glass, now has 14 independent legal entity enterprises, with assets of over 10 billion yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. The group covers 10 prefecture-level cities in six provinces including Heilongjiang,Hebei, Shandong.,Henan, Anhui and Sichuan, with 4000 employees.

It has three glass plates.They are float glass ,special glass and deep-processing glass. The special glass unti is composed of ENGYANG TRIUMPH SILICON MATERIALS CO., LTD. 、 Qinhuangdao Scinan Specialty Glass Co.,Ltd.、Triumph Bnegbu Glass Co.,Ltd. and CNBM(PUYANG) PHOTOELECTRIC MATERIALS CO., LTD.

Fengyang Triumph Silicon Materials Co., Ltd. Is the subsidiary of China National Building Material Group Co., Ltd., a Fortune 500 company. Fengyang Triumph production line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights.The company mainly produces borosilicate float glass 3.3 and borosilicate float glass 4.0.

The company plans to build a fully electric fused borosilicate float galss 3.3 production line with a melting capacity of 30t/d. It is expected that the ignition conditions will be available in 2023.

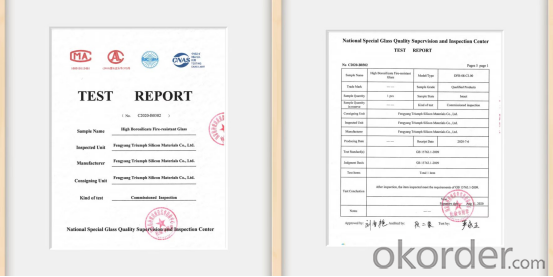

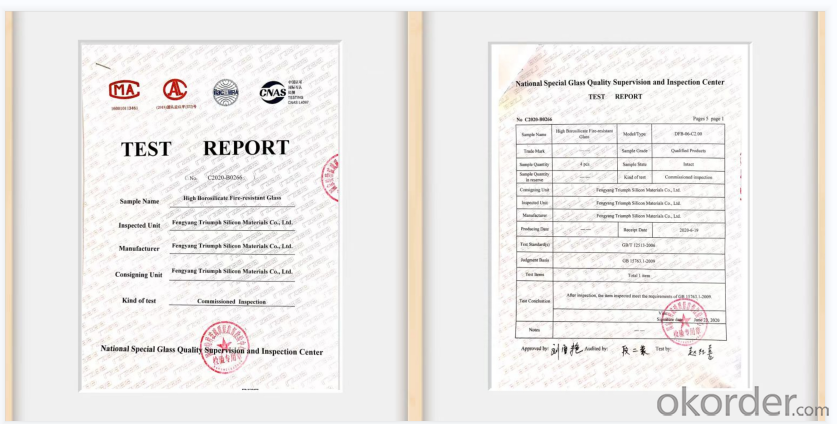

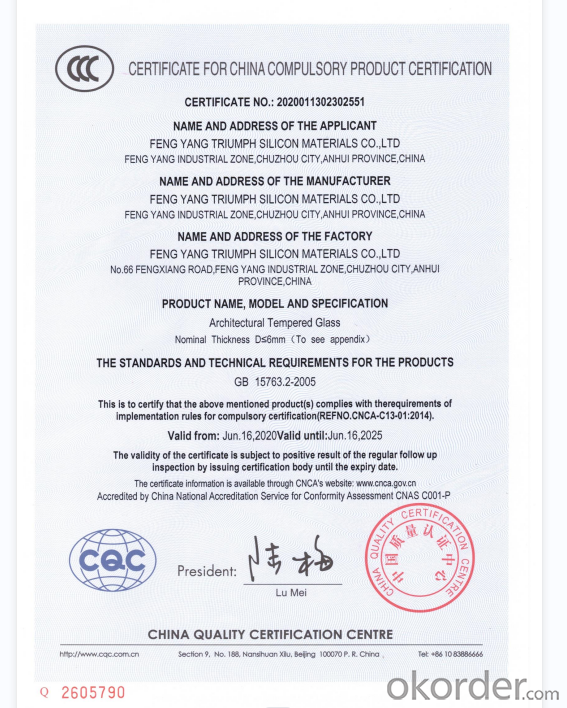

Our company has passed the SGS certification 、SISO9001:2015 certification, and we have also passed the Certificate China National Compulsory Product Certification.Our company has obtained more than 20 national patents,and fireproof glass test report.

- Q: What is the difference between calcium silicate board and cement pressure plate?

- One thing, formerly known as cement pressure plate, are now changed to calcium silicate board, referred to as calcium calcium board.

- Q: Ceiling gypsum board and plastic plate which cheap?

- The price can not be so constant, all kinds of materials are expensive and cheap, theoretically 60x60 gypsum board will be cheaper than plastic, you can open the plaster and glass.

- Q: How effective! Long time will not fall, I know that hanging grid cloth powder cement mortar, I think this kind of spread to move Ji Jiu Bang Bao magic also out of the fast, there is no more convenient construction methods, such as hanging mesh and then spray cement Mortar plus 107 mortar! Now want to reduce the cost do not want the powder cement mortar, my place when the outdoor, 20 meters long, 5 meters high a new wall, grass is more steel

- A long time will fall out!

- Q: See a set of plans, the grass-roots level: building wall + cement leveling + calcium silicate board 粻 窢 窢 Gang drink assessment of Taiwan Terrier County + waterproof gypsum board + latex paint. Do not know right? Room location for the shower, shower layer height of 2.8m, 2.5 meters above the height of the stone, 2.5-2.8 meters for the latex paint can: calcium silicate board + blockboard + wood finishes? Urgent, please advise, very grateful! More

- Calcium silicate board and gypsum board is two similar materials, but because the material is not the same, so the hardness, flexibility are not the same, calcium silicate board 粻 窢 窢 蕺 蕺 蕺 assessment of Taiwan Terrier County can also directly brush latex paint , Do not need to go back and then paste the gypsum board to do latex paint, if you do not feel comfortable can do plaster board to do latex paint.

- Q: Double layer 12 mm thick calcium silicate board with what keel ceiling

- Light steel keel

- Q: Fire board fire resistance limit of 3 hours?

- Yes, you'd better find the production of refractory board (fire board) manufacturers understand!

- Q: Calcium silicate board and aluminum plastic plate which is good

- Calcium silicate board is a cement fiber board, with gypsum no hair relationship, is better waterproof, senior hotel bathroom commonly used.

- Q: 3.6 meters high, the ceiling has been equipped with fire pipes, air conditioning pipes, and now to do 2.8 meters of light steel keel calcium silicate board wall, how to fix the dragon keel, there is no regulation of governance Cui Huang Chao Chao The keel must be reinforced to the top? More

- It depends on how you do this cut off, there is no pull force, can be connected to each other. Do not have to go to the top of the.

- Q: Silicon calcium board ceiling can be used in home improvement bathroom? why?

- Can not be summed up in the home improvement is often used silicon calcium board silicon calcium board with light weight, high strength, moisture, corrosion, fire, another significant feature is that it is easy to re-processing silicon calcium board mainly composed of gypsum, there is a call Calcium silicate, calcium silicate is composed of quartz, mica, wood fiber and other ingredients. Followed by the use: calcium calcium board is mainly used for indoor ceiling, and it also high-grade, mid-range, low-grade distinction, the best is solid silicon calcium board, moisture, fire, pollution, low carbon, clean surface, durability it is good. The calcium silicate board can be used for indoor and outdoor partitions, ceiling, surface decoration, firewall, fire ceiling, steel fire, high temperature insulation and many other environments, calcium silicate board also has good or bad points, Harmless to the human body, poor raw materials sucks, containing asbestos, carcinogenic.

- Q: Ceiling silicon calcium board and mineral wool board which is better

- I suggest you still use calcium silicate board, the first mineral wool board thickness, increasing the keel pressure, easy to cause the ceiling subsidence. Second, mineral wool board which is easy to produce some insects. The third mineral wool board of the set of exclusive anti-emblem salvage tank fire performance no calcium silicate board is good, the fourth mineral wool board damp easily yellow, hygroscopicity is not good. And calcium silicate board will not have the above shortcomings, if it is ceiling ceiling 600 * 600, then the thickness of calcium silicate board 4mm can achieve the effect of mineral wool board 15mm thickness, while the biggest advantage of calcium silicate board is not combustible A-class fire, moisture is very good, environmentally friendly building materials. So I recommend you use calcium silicate board, the price is better than the mineral wool board

Send your message to us

Fireproof glass windows and doors((Borosilicate Float glass 4.0)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Fengyang Triumph Silicon Materials Co., Ltd.

Fengyang Triumph Silicon Materials Co., Ltd.