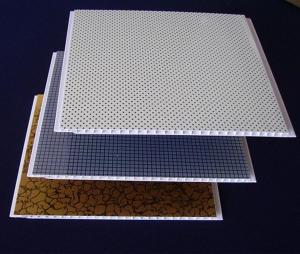

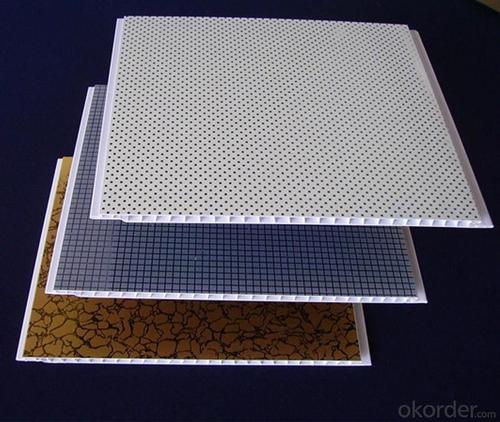

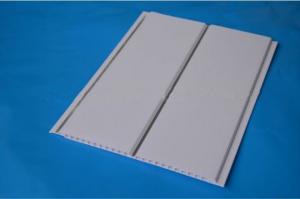

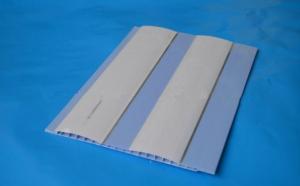

waterproof interlock pvc wall panel interior wall coating panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

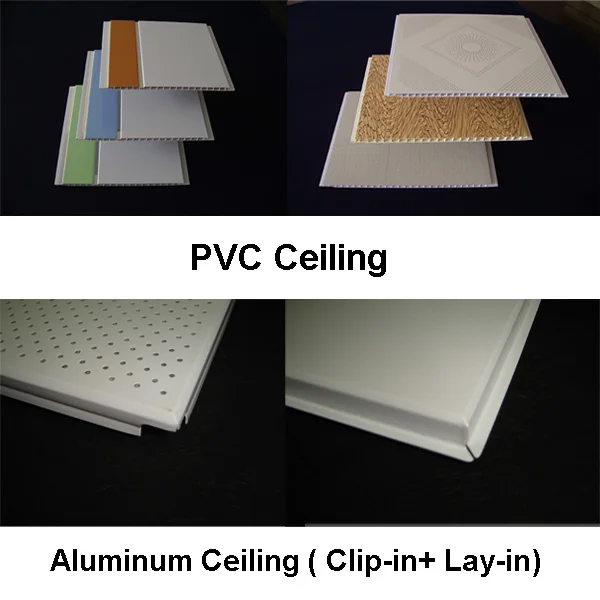

pvc ceiling tiles pvc panels for sale

Specification:

1.Width: 0.915,1,1.22,1.56,2.05m

2.Thickness: 1~40mm

3.Colors: as your requirementThickness: 1mm~25mm

Good features:

1. Light weight,good tenacity, high rigidity

2. Fireproof and flame retardant

3. Good insulation

4. No sopping, no deformation

5. Easily to processed

6. Good plasticity, being an excellent thermoform material

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. With imported dyes, unfading and anti-aging

Applications:

Advertising: signs, exhibition stands, routing sheets, etc..

Industry: Manufacturing industries, control cabinets, etc., and warning signs.

Construction: Wall cladding, sandwich panels, interior decoration etc.

pvc ceiling tiles pvc panels for sale

PVC Sheet-applied treatments:

Materials processing: Cut; Drilling; Milling; nail etc.

Heat application: wisting, bending; Resource work; Heat styling

Other: Digital Printing; Application of alternative soil; Application sheets; Painting

Produce Arrange:

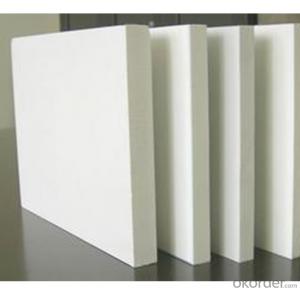

PVC foam sheet | |||||

Specifications | Thickness(mm) | Densityg/cm3) | MOQ(pc) | Color | Application |

0.915*1.83 | 1--10 | 0.5-0.8 | 1000 | White | Sign board |

1.22*2.44 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

1.56*3.05 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

2.05*3.05 | 1--10 | 0.6-0.9 | 500 | White/Colored | |

PVC Celuca Sheet | |||||

Specifications | Thicknessmm | Densityg/cm3) | MOQ(pc) | Color | Application |

1.22*2.44 | 4--40 | 0.5-0.8 | 500 | White | Furniture |

1.56*3.05 | 8--40 | 0.6-0.8 | 500 | White | Furniture |

PVC rigid sheet | |||||

1.22*2.44 | 1--3 | 1.42 | 500 | Sign board |

Our main products in CNBM:

pvc ceiling tiles pvc panels for sale

- Q: Pvc buckle board ye demolition?

- Oh, I'll answer you! I am a decoration worker! Gossip less, first of all you look at your home PVC top of the buckle which one of the last piece of the width of the small, because the installation of the last piece of time, not necessarily the whole block! For example, the East is small, so that we have to start from the beginning to start! Find a blade inserted from the buckle slit, push to the corner of the corner, (if loose, then hand can also) you will see the last piece of a buckle only two sides of the corners attached! And then to the left or right to push, then congratulations you can get off the buckle! The last piece of demolition, how to split behind, is the individual will be! I do not have to install! How to install how to install!

- Q: What is the difference between steel and PVC gussets?

- Plastic steel, PVC, aluminum plate is three different materials Plastic steel and plastic doors and windows is almost, PVC is the lowest level of anti-aging plastic, aluminum plate is relatively thin aluminum plate anti-aging level is the best. Price and quality level is proportional to, PVC two, thirty-one square, about 40 square meters of steel and aluminum buckle in a hundred or so a square.

- Q: Do the closet door density board is good or PVC good

- If you want to paint, then use MDF, if it is of course, is a pvc, and there is no good question

- Q: How to paste the pvc board to the wall

- To use a kind of interior decoration of the environmental glue, they are specialized in producing environmentally friendly plastic wallpaper and after-sales service of the regular manufacturers.

- Q: VC plastic buckle the corners of the corners is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall ...

- Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q: What is the difference between acrylic and PVC?

- In addition to transparent, of course, can also be integrated into other colors, that is more brittle, the ground will crack, and so on, but pvc can not be transparent ~ This is the biggest difference; pvc is a good toughness, can be bent, like some card products is Pcv ~ do not know if this can answer the question of the landlord ~ Thank you ~

- Q: What are the disadvantages of using PVC pipe cast-in concrete for house water supply line against G.I?

- pvc won't last this is best

- Q: In electrical drawing, how many PVC circular boxes needed if you have 6 ceiling lights?

- it would be 6 obvioulsly a box for each of the light's connection and also to hang the light? No offense but that question doesn't really make sense?

- Q: KT board and PVC board, as well as ABS board What is the difference between ah

- Kt board is polystyrene material (lunch box material) foam out of the plate, the biggest feature is the light mainly used for indoor advertising; Pvc plate - also known as pvc foam board or Andy board, its chemical composition is polyvinyl chloride. Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling. (The general plastic pipe with this material is called pvc but not foam) ABS board ABS board ABS board is a new material in the sheet industry. Its full name is acrylonitrile / butadiene / styrene copolymer plate. English name Acrylonitrile-butdiene-styrene, is the largest production, the most widely used polymer. It will PS, SAN, BS various properties organically unified, both tough, hard, just equal balance of excellent mechanical properties. (Refrigerator, air conditioning these are used in this material) Some nouns do not necessarily know what is written in brackets is usually easy to see you see, the main you really understand the

- Q: 2mm thick pvc plastic floor is generally one square meter multiple

- PVC is soft and hard, transparent and opaque, the product is different, the formula is also different, plus plasticizer and filler after the number of no difference, the density is very different, ordinary hard transparent PVC is 1.34 g / cubic Centimeters or so, opaque hard PVC to 1.7 also have, transparent soft PVC minimum to 1.22 or so, opaque do not know. On the fold 1.5g / cubic centimeters = 1500KG / cubic meter. 2mm thick pvc a square meter volume is 0.002 square meters. So 2MM PVC sheet about 3KG weight.

Send your message to us

waterproof interlock pvc wall panel interior wall coating panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords