PVC Ceiling Panels Price Philippines - Nice Looking PVC Ceiling Design Hot Sell

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

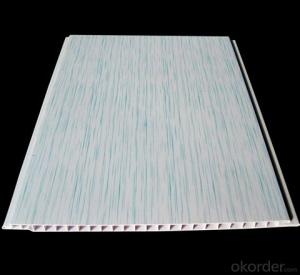

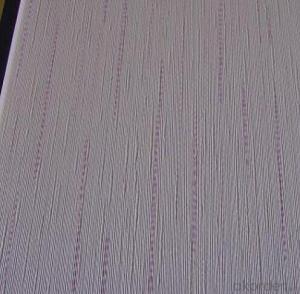

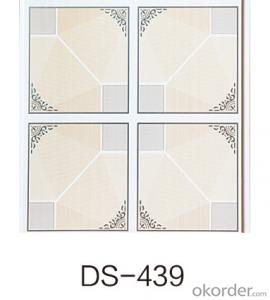

PVC Ceiling for Interior Decoration

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel with high quality and competitive price. And monthly output up to 480,000 Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Specification:

1) Easily installation,surface is smoothness,flatness,without gap when concatenated.

2) High intensity,good quality,not easy to deformation,resist erosion,mothproof,sound insulation,waterproof,fireproof,aging-resisting,durable.

3) It can be processed by drilling,sawing,nailing.Hot bending,hot-folded.

4) Interior decoration for ceiling,wall.Easy cleaning,healthy and environmental.

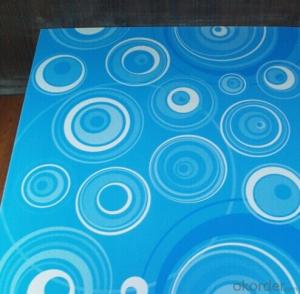

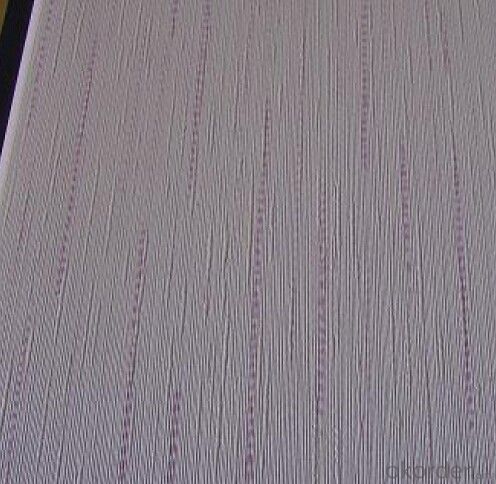

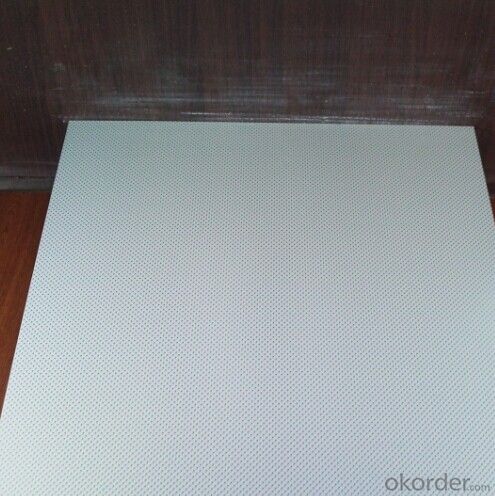

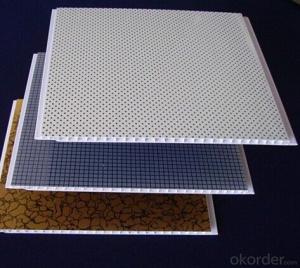

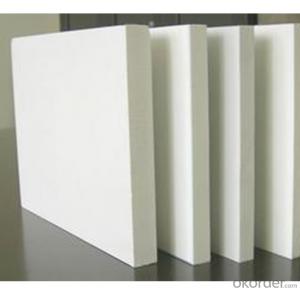

3.Image

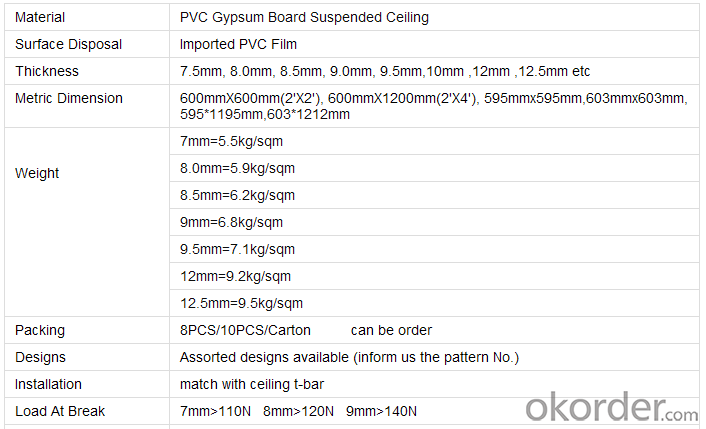

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

- Q: , Pvc board, wood keel ceiling, contractors, not packing materials, buy their own wooden screws, mainly to do the bathroom, toilet kitchen, open at 4 meters above, how much money a square meter can do

- PVC board a square meter dozens to hundreds of fast money.

- Q: Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- No hopefully I wouldn't be daft enough to do that. I don't have a sun roof but I can just imagine how stupid you would feel stuck there with no way out!

- Q: Pvc floor how

- This thing is more convenient to save money!

- Q: Pvc floor green? Can you pave it in the bedroom?

- First, the plastic floor can not be used outdoors. The reason for using in public places is not because the floor is not environmentally friendly, but the plastic floor is more wearable. Secondly, in terms of environmental protection, some domestic flooring, although the environmental protection standards of Europe and the United States, but more environmentally friendly than to strengthen is sure. The golden mouse floor is nice. If the economic strength to allow, then choose to import better.

- Q: Pvc foam board and wood-plastic plate difference?

- Wood-plastic board generally add wood for the powder or bamboo powder, rice bran, etc., there are some wood-plastic plate which has added foam agent. Foam plate section with holes, the density is light

- Q: With the area and thickness of the KT board and PVC board which is more expensive?

- Pvc also has a very cheap, that is, the density of the foam is not high. Kt board also has a high density, more expensive. This is generally very rare. ? Ordinary common pvc board expensive

- Q: 2mm thick pvc plastic floor is generally one square meter multiple

- PVC is soft and hard, transparent and opaque, the product is different, the formula is also different, plus plasticizer and filler after the number of no difference, the density is very different, ordinary hard transparent PVC is 1.34 g / cubic Centimeters or so, opaque hard PVC to 1.7 also have, transparent soft PVC minimum to 1.22 or so, opaque do not know. On the fold 1.5g / cubic centimeters = 1500KG / cubic meter. 2mm thick pvc a square meter volume is 0.002 square meters. So 2MM PVC sheet about 3KG weight.

- Q: What is the difference between acrylic and PVC board?

- PVC board stability is poor, easy to decompose when processing, generally with the same color of the acrylic than the background will be yellow.

- Q: Pvc foam board what materials?

- Product Usage Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling.

- Q: What is the difference between PVC board and PC board?

- Acrylic 1. Transparent high, light is not easy to deformation, good guide optical rotation. 2. PMMA difficult to fire, can slowly burn. 3. Unsuitable alcohol, ketone, alkali, soluble in aromatic hydrocarbons, oxidized hydrocarbons (trioxide can be used as a binder). 4. Easy to shape, size and stability. 5. Impact resistance and surface hardness are slightly worse, easy to rub the price is very expensive PVC is very soft ... can be the same as the paper folded 2. and acrylic than ... acrylic is very easy to rotten 3.PVC will not rotten ... Organic board 1. partial yellow .. there are dregs .. material surface potholes .2. Thickness uneven .... he and acrylic like .. also known as advertising board ... very cheap

Send your message to us

PVC Ceiling Panels Price Philippines - Nice Looking PVC Ceiling Design Hot Sell

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords