Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

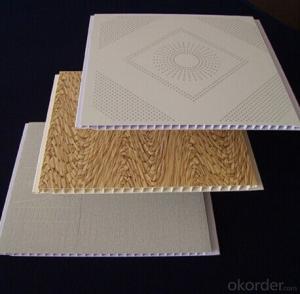

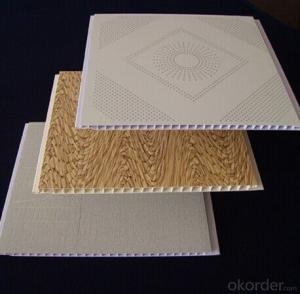

Newly designed PVC Ceiling Panels:

1.ISO9001,Soncap,CE&SGS

2. Easy-clean surface & maintenance free

3.Various designs & spec

Newly designed PVC Ceiling Panels

Company Information

We are a professional PVC Ceiling panels manufacture since 1992, offering hundreds of patterns and colors of PVC panel and monthly output up to 480,000 Sqm.

Product Advantages:

Normal Packing: 10 pcs per PE Film Package with carton End cap at both end of the package.

Special Packing: 1. transparent film between two panels to protect the surface; 2. carton box with 10 pcs or 20 pcs per carton; 3. as requested. Special Packing fees extra.

Shipping: 7-10 days upon receipt of deposit for a 20GP and 10-15days for a 40'HQ.

.

Product Description

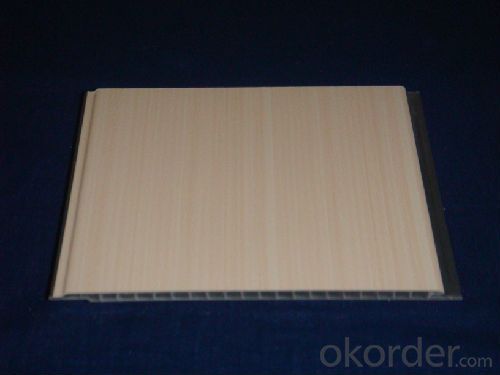

20cm*7.5mm groove PVC ceiling panels, for Africa Countries, India, Mid-east and Europen markets,with CE, ISO9001:2008, SONCAP,SGS certification

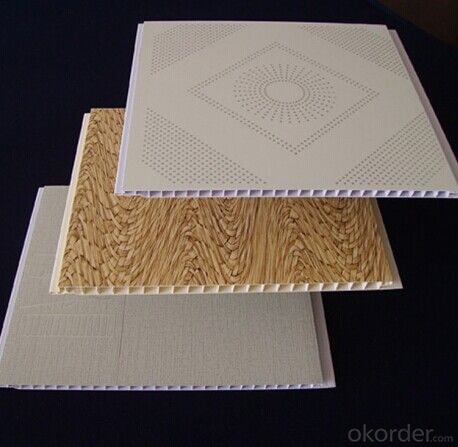

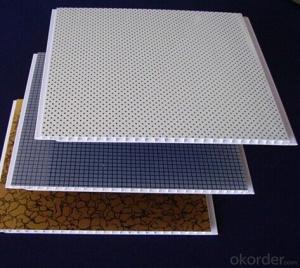

Different types of PVC ceiling we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

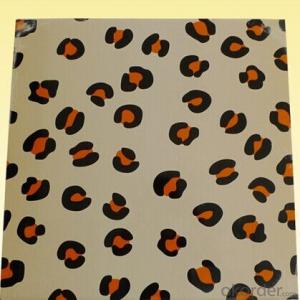

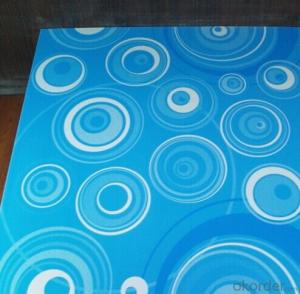

4, Transfer Printing PVC Panel

The hottest specifications of PVC ceiling on the market:

Thickness: 4mm/4.5mm/6mm/7.5mm/9mm/10mm/11mm/12mm

Length: 3m-5.95m

Width: 200mm, 250mm, 300mm, 600mm

PVC percentage: 35%-75%

Any other specifications are also available here.

Main Product Features:

| Newly Designed PVC Ceiling Panels | ||||||||

Lucky PVC | Width | Thickness | N.W. | Packing | Loading in 20’GP (5.8m length) | Loading in 40'HQ (5.95m length) | ||

| mm | mm | Kg/Sqm |

| packages | amount/Sqm | packages | amount/Sqm |

Flat Panel | 100 | 7.5 | 2.2 | 10 pcs/PE film package | 736 | 4268.8 | 1610 | 9579.5 |

| 150 | 7.5 | 2.3 |

| 496 | 4315.2 | 1084 | 9674.7 |

| 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 1829 |

|

| 10 | 3.8 |

| 276 | 3201.6 | 598 | 7116.2 |

| 240 | 9 | 2.7 |

| 254 | 3535.7 | 566 | 8082.5 |

| 250 | 4 | 1.5 |

| 558 | 8091 | 1070 | 15916 |

|

| 4.5 | 1.65 |

| 495 | 7177.5 | 941 | 13997 |

|

| 6.5 | 2.1 |

| 333 | 4828.5 | 758 | 11275 |

|

| 7 | 2.2 |

| 315 | 4567.5 | 704 | 10472 |

|

| 7.5 | 2.3 |

| 297 | 4306.5 | 600 | 8925 |

|

| 8 | 1.6 |

| 279 | 4045.5 | 614 | 9133 |

|

| 11 | 3.4 |

| 189 | 2740.5 | 432 | 6426 |

| 300 | 9 | 2.3 |

| 198 | 3445.2 | 429 | 7658 |

Groove Panel | 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 10829 |

|

| 7.5 | 2.2 |

| 364 | 4222.4 | 785 | 9341.5 |

| 250 | 8 | 2.7 |

| 279 | 4045.5 | 590 | 8776 |

| 300 | 9 | 3 |

| 176 | 3062.4 | 418 | 7461.3 |

Wave Panel | 250 | 8(four) | 3.2 |

| 238 | 3451 | 564 | 8389.5 |

| 250 | 8(three) | 3.7 |

| 238 | 3451 | 564 | 8389.5 |

Suspended Ceiling | 595 | 7 | 2.1 | 20pcs/carton | 468 | 3313.7 | 1197 | 8475 |

| 605 | 7 | 2.2 |

| 450 | 3294.2 | 1160 | 8213 |

Product Specifications:

Application of pvc ceiling

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

1, Household Ornament: Wall and ceiling of indent independent house bathroom

2, Public and Management Place: Toilet of building and hall

3, Common Office: Ceiling of business Place

Feature of pvc ceiling:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

4) Interior decoration for ceiling. Easy clearing, healthy and environmental.

Images:

- Q: Pvc how to heat the deformation of soft board, to make their own shape

- Small on the hair dryer, the factory on the infrared or oven heating

- Q: PVC foam board on the market now uneven quality, is said to have a true crust and false crust, but do not know how to distinguish, and asked, Baotian Hi-Tech production of PVC crust foam board quality? Please tell you please.

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality belongs to the high-end

- Q: Can the interior wall be decorated with pvc board?

- PVC board is a vacuum plastic film, used for various types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: Pvc floor with what glue

- It depends on the use of places and the environment to choose, but also depends on the floor category to choose. As you use the PVC sheet flooring, the use of water-based sheet glue, the use of PVC coil floor, the use of water-based membrane glue. If in ordinary areas, the general water-based glue can be, and if in wading places, you must use two-component epoxy resin. Different floor thickness and physical properties, the choice of glue is also different, poor floor stability, the need to choose a higher cost of strong adhesive glue, the floor stability is good, but you can choose ordinary glue.

- Q: I'm installing a computer and have to drop both power and Ethernet from the ceiling. Will i get interference running the 2 wires close together?

- Yes you can put them together and no you will not receive interference

- Q: PVC board which general specifications, thickness, PVC processing parts where can be found? Insulation material plus

- Product thickness: 0.8-30mm Product width: 1300mm 1500 mm Accessories processing: PVC processing parts Reed can be produced according to customer needs, can be hot-rolled, hot, CNC, and so on. PVC soft board: laminated sheet: 2-60mm Product width: 1000mm × 2000 mm PVC transparent board: high-strength, high transparent plastic sheet, the product color is white, sapphire blue, brown, brown and other varieties. The product is high strength, high transparency, good weather resistance, non-toxic, health, physical properties better than plexiglass. Widely used in equipment protection board, interior, drinking water tank, liquid level display. Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm PVC soft board (coil): surface gloss, soft. There are brown, green, white, gray and other colors to choose from, the product material, fine production, widely used. Features Soft and cold, wear, acid, alkali, corrosion resistance, excellent tear resistance, with excellent weldability, physical properties than rubber and other coil. Used in chemical, electroplating, electrolytic cell lining, insulation cushion, trains, automotive interiors and auxiliary materials.

- Q: Colored PVC board is what kind of board ah, can not paint

- Can not paint their surface seal glaze can not hold paint even strong coating will not have a good effect

- Q: Pvc board why the sun will be deformed directly

- 60-80 ℃ or so

- Q: I have a finished basement, and need to add a 2nd waterheater for a new bathroom shower that acts as a carwash, flowing 24gpm! Is there any way I can tie into the existing 3pvc vent pipe for this 2nd waterheater? Adding a 2nd vent would require tearing into the ceiling, which would suck! Theoretically, you could add a couple of 3 PVC motorized ball valves, but it would be much easier to try to keep things simple.

- Hope this helps You may have too also include an upgrade into the size of your fresh air supply

- Q: PVC door cut how bad repair

- PVC door repair has a special fill ash putty, make a good gray after the polished smooth And then use the same color paint spray paint treatment Generally more well-known brands will have material processing

Send your message to us

Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords