FRP Roofing Panel - Hot Pressed SMC Sheet for Water Tanks with Superior Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

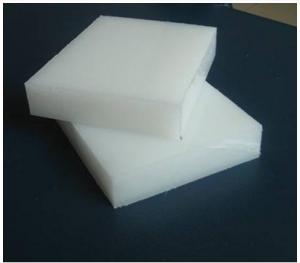

SMC and BMC are abbreviations of respectively Sheet Molding Compound and Bulk Molding Compound. SMC and BMC form a family of structural, fiber reinforces thermosetting resins. SMC and

BMC are intermediate materials from which a large variety of products can be manufactured by compression molding or injection molding. Base materials of SMC and BMC are, generally spoken, unsaturated polyester resins, glass and mineral filler materials, such as chalk or aluminum trihydrate. The composition of the compounds can be adapted to the application where it is used for. Specific properties such as flame retardancy, surface quality and paintability can be achieved by adding specific, functional materials. SMC and BMC product are used in a very broad range of applications

Product Traits

It is the water tank of new type adopted in the world presently,and is assembled by wholly good qualitied SMC plates.

We can assemble water tank with volume from 1m3 to 1000m3, easy to change the volume.

Sealing belt is non-toxic with high elastic property and fastened which means it has high strength.

It’s widely used in mine industry, enterprises&public institutions, house, hotels etc.

Food grade resin is adopted, so the quality of water is good and clean, without pollution, high strength, light weight, corrosion resistante, nice appearance, long service life, easy to maintenance etc.

Advantages

Sheet Molding Compound is a fiber-reinforced material, which consists primarily of a thermosetting resin glass fiber.

With high tech material—SMC, which has high impact compressive, flexural and tensile strength along with temperature stability.

Technical Parameter & Specification

| Properties | Unit | Value | |

| Appearance | - | Smooth surface, no airbubble and crack,no sundries | |

| Density | g/cm3 | 1.85~1.92 | |

| Water absorption | mg | ≤20 | |

| Molding shrinkage ratio | % | ≤0.15 | |

| Heat distortion(A) | °C | ≥220 | |

| Impact strength (Charpy in-notched) | KJ/m2 | ≥90 | |

| Flexural strength | MPa | ≥135 | |

| Insulationresistance | Under normalconditions | Ω | ≥1.0×1013 |

| Immerged inwater for24 hours | ≥1.0×1012 | ||

| Dielectric Strength(in 90°C oil) | MV/m | ≥12.0 | |

| Dissipation Factor(1 MHz) | — | ≤0.015 | |

| Permittibity(1 MHz) | — | ≤4.5 | |

| Arc Resistance | S | ≥180 | |

| Proof Tracking Index(PTI) | V | ≥600 | |

| Flammability | Class | FV0 | |

| Temperature | — | ≥155 | |

Application

The water tank has been widely used in residential buildings, hotels, office buildings, R&D buildings, schools, malls, restaurants and other public facilities as well as places with high requirements for water quality, such as hospitals and food processing plants.

FAQ

How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

- Q: Are FRP roofing panels compatible with solar panel installations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are compatible with solar panel installations. FRP roofing panels are known for their durability, lightweight, and weather resistance, making them suitable for supporting solar panels. These panels can provide a solid and secure base for solar panels to be installed on, ensuring stability and longevity for the entire system. Additionally, FRP roofing panels have excellent thermal insulation properties, which can help regulate the temperature of the solar panels, enhancing their overall performance. Moreover, FRP panels are often translucent, allowing light to pass through and reach the solar panels, maximizing their energy generation potential. Overall, FRP roofing panels are a reliable and compatible option for solar panel installations.

- Q: Are FRP roofing panels suitable for residential balconies or terraces?

- Yes, FRP roofing panels are suitable for residential balconies or terraces. FRP (Fiberglass Reinforced Plastic) roofing panels offer durability, weather resistance, and low maintenance, making them a suitable choice for outdoor spaces. These panels are lightweight, easy to install, and provide excellent protection against UV rays, moisture, and corrosion. Additionally, FRP roofing panels can be designed to mimic the appearance of traditional roofing materials, enhancing the aesthetics of residential balconies or terraces.

- Q: Can FRP roofing panels be installed on greenhouses or botanical gardens?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on greenhouses or botanical gardens. FRP panels are lightweight, durable, and have excellent thermal insulation properties, making them ideal for such structures. Additionally, FRP panels are resistant to UV radiation, chemicals, and moisture, which are common in greenhouse and botanical garden environments. This makes them highly suitable for protecting plants from the elements while allowing sufficient natural light transmission. The installation of FRP roofing panels in greenhouses or botanical gardens can provide a cost-effective, long-lasting, and aesthetically pleasing solution for maintaining a controlled environment for plant growth.

- Q: Can FRP roofing panels be used for museums?

- Yes, FRP roofing panels can be used for museums. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, flexibility, and resistance to corrosion, making them suitable for protecting valuable artifacts and exhibits in museums. Additionally, FRP panels can provide natural lighting and UV protection, creating a conducive environment for showcasing artwork and preserving historical items.

- Q: Can FRP roofing panels be used for public transportation stations or terminals?

- FRP roofing panels are an ideal option for public transportation stations or terminals. These panels are widely used in construction for their strength, durability, and ability to resist corrosion and weathering. They are lightweight and simple to install, making them perfect for situations where speedy installation is vital, such as public transportation facilities. Moreover, FRP panels can be designed to provide exceptional insulation and noise reduction, ensuring a comfortable experience for commuters. In conclusion, FRP roofing panels offer a cost-effective and dependable solution for public transportation stations or terminals.

- Q: Can FRP roofing panels be installed in low-pitched roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed in low-pitched roofs. FRP panels have excellent waterproofing properties and can be effectively used in roofs with a low slope. However, it is important to ensure proper installation and use appropriate sealants to prevent any potential leaks.

- Q: Can FRP roofing panels be used for walkways?

- The main purpose of FRP (Fiberglass Reinforced Plastic) roofing panels is for roofing, not for walkways. Although they are lightweight, durable, and resistant to certain environmental elements, using FRP panels for walkways may not be suitable. This is because their smooth surface can become slippery when wet or icy. Furthermore, FRP panels may not have the necessary structural support or load-bearing capacity to safely accommodate foot traffic. When designing walkways, it is crucial to prioritize safety and select materials that are explicitly designed and tested for this purpose. Non-slip concrete, pavers, or other suitable options are advisable choices.

- Q: Are FRP roofing panels suitable for coastal areas with high salt exposure?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for coastal areas with high salt exposure. FRP roofing panels are known for their durability and resistance to corrosion, making them an excellent choice for areas where there is a high concentration of salt in the air. The fiberglass reinforcement in FRP panels provides additional strength and stability, making them highly resistant to the corrosive effects of saltwater and salt-laden air. This makes FRP roofing panels an ideal solution for coastal areas where traditional roofing materials may deteriorate quickly due to salt exposure. Additionally, FRP roofing panels are also resistant to UV radiation, which is another common factor in coastal environments. Therefore, FRP roofing panels provide a long-lasting and reliable roofing solution for coastal areas with high salt exposure.

- Q: Can FRP roofing panels be used in curved or sloped roofs?

- Yes, FRP roofing panels can be used in curved or sloped roofs. These panels are flexible and can easily be moulded or bent to fit the shape of the roof, making them suitable for various architectural designs and applications.

- Q: What is the insulation value of FRP roofing panels?

- The insulation value of FRP (Fiberglass Reinforced Plastic) roofing panels can vary depending on the specific type and thickness of the panel. However, FRP roofing panels generally have a lower insulation value compared to other roofing materials such as foam or metal panels. The insulation value is typically measured in terms of R-value, which indicates the resistance to heat flow. FRP panels typically have an R-value between 2 and 3 per inch of thickness, which means they provide some level of insulation but may not be as effective as other materials in terms of thermal performance. It is important to consider other factors such as climate, building design, and additional insulation measures when evaluating the overall insulation properties of FRP roofing panels.

Send your message to us

FRP Roofing Panel - Hot Pressed SMC Sheet for Water Tanks with Superior Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords