Frp Roof Panels Southerland - Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thinkness

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility. Today, we’re planning to win more market shares in the world and let more customers know us.

Product Traits

1)High light transparency

2)Light weight and high strength

3)Corrosion and impact resistance

4)Anti-UV, anti-static, insulation

5)Accurate cross-section size

6)The length of the random cutting and more

7)Widely used in industrial plants, large-scale treasury markets, greenhouse, aquaculture and tourism

8)Used as roof, wall panel and more

9)Supports good lighting effect

Product Advantage

Corrosion Resistant

Light Weight,High Strength and Impact & Fatigue Resistant.

Non-Conductive & Non-Magnetic

Maintenance Free

Fire Retardant

Dimensional Stability

Easy Assembly

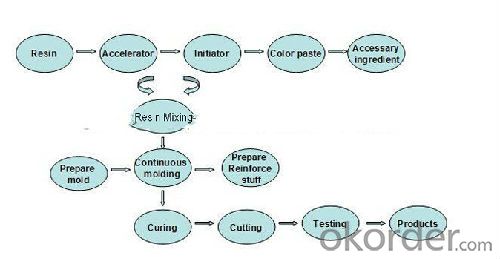

Production Process

Specification

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

Photos

The Raw Materials of WANT Pultruded Profiles Fiberglass plank

For services in different extreme environments, WANT provides a number of choices for rovings, mats, resin and others to meet customer's demands. Both orthophthalic and isophthalic polyester resin are most commonly used, whilst vinyl ester resins are also available upon request. We can provide profiles of various shapes and colors with alternative options for various mats, veils, as well as other additives for different application.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can FRP roofing panels be used for carports or parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can indeed be used for carports or parking structures. FRP panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for such applications. Additionally, FRP panels offer UV protection and can withstand harsh weather conditions, making them a reliable choice for carports and parking structures.

- Q: Are FRP roofing panels resistant to bird damage?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are generally resistant to bird damage. The durable nature of FRP makes it less susceptible to scratches, pecks, or punctures caused by birds compared to other roofing materials such as shingles or metal. However, it is important to note that no material is completely impervious to bird damage. In rare cases, aggressive bird behavior or large birds with strong beaks may still be able to cause some damage to FRP roofing panels. To minimize the risk of bird damage, it is advisable to make sure that the panels are properly installed, regularly inspected, and any potential bird entry points are sealed off. Additionally, taking preventive measures like using bird deterrent devices or netting can further discourage birds from perching or nesting on the roof, thereby reducing the chance of damage.

- Q: Are FRP roofing panels resistant to bird damage?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are generally resistant to bird damage. The durable nature of FRP makes it less susceptible to scratches, pecks, or punctures caused by birds compared to other roofing materials such as shingles or metal. However, it is important to note that no material is completely impervious to bird damage. In rare cases, aggressive bird behavior or large birds with strong beaks may still be able to cause some damage to FRP roofing panels. To minimize the risk of bird damage, it is advisable to make sure that the panels are properly installed, regularly inspected, and any potential bird entry points are sealed off. Additionally, taking preventive measures like using bird deterrent devices or netting can further discourage birds from perching or nesting on the roof, thereby reducing the chance of damage.

- Q: Can FRP roofing panels be used for skylights in entertainment venues?

- Yes, FRP roofing panels can be used for skylights in entertainment venues. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and have excellent light transmission properties, making them suitable for skylights in various applications, including entertainment venues. They provide natural lighting, enhance aesthetics, and can withstand harsh weather conditions, making them a popular choice for skylights in such spaces.

- Q: Can FRP roofing panels be installed over shingles?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed over shingles in certain situations. However, it is important to consider a few factors before proceeding with this installation method. Firstly, it is crucial to assess the condition of the existing shingles. If the shingles are damaged, deteriorated, or uneven, it is recommended to remove them before installing the FRP roofing panels. This ensures a smooth and stable surface for the panels to be secured onto. Additionally, the weight of the FRP panels should be taken into account. The added weight may exceed the load-bearing capacity of the roof structure, especially if there are multiple layers of shingles already present. It is advisable to consult a structural engineer or a professional roofing contractor to assess the roof's capacity and determine if any reinforcements are necessary. Furthermore, proper installation techniques must be followed to ensure a secure and watertight seal. The panels should be fastened with the appropriate fasteners, such as screws or nails, into the underlying roof structure. It is crucial to follow the manufacturer's guidelines and recommendations for installation to avoid any potential issues. Lastly, it is worth noting that installing FRP roofing panels over shingles may affect the warranty on both the shingles and the FRP panels. It is advisable to review the warranty documents provided by the manufacturers to understand the potential implications. In summary, while it is possible to install FRP roofing panels over shingles, it is important to consider the condition of the existing shingles, the weight limitations of the roof structure, and to follow proper installation techniques. Consulting with professionals and reviewing warranty information is highly recommended to ensure a successful and long-lasting installation.

- Q: Can FRP roofing panels be used for outdoor storage sheds or workshops?

- Yes, FRP roofing panels can be used for outdoor storage sheds or workshops. FRP (Fiberglass Reinforced Plastic) panels are known for their durability, weather resistance, and low maintenance requirements, making them suitable for outdoor applications. They provide excellent protection against UV rays, moisture, and extreme temperatures, ensuring that the contents of the shed or workshop remain safe and secure. Additionally, FRP panels are lightweight, easy to install, and have high strength, making them a cost-effective and practical choice for outdoor storage sheds or workshops.

- Q: Can FRP roofing panels be used for canopies or awnings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for canopies or awnings. FRP panels are lightweight, durable, and resistant to corrosion, making them suitable for outdoor applications. They are also available in different colors, allowing for customization and aesthetic appeal. Additionally, FRP panels are easy to install and maintain, making them a popular choice for canopies and awnings in various settings such as residential homes, commercial buildings, or recreational areas.

- Q: Can FRP roofing panels be installed on both residential and commercial car dealerships?

- Yes, FRP roofing panels can be installed on both residential and commercial car dealerships. FRP panels are versatile and durable, making them suitable for various applications, including roofing. They offer excellent protection against weather elements and are lightweight, which makes installation easier. FRP panels also come in different colors and styles, allowing for aesthetic customization to suit the needs of both residential and commercial car dealerships.

- Q: Are FRP roofing panels resistant to chemicals?

- FRP roofing panels, commonly known as Fiberglass Reinforced Plastic, offer a high level of resistance to chemicals. These panels are composed of a combination of fiberglass and a plastic resin, resulting in outstanding chemical resistance against acids, alkalis, and solvents. The chemical resistance of FRP panels makes them an excellent choice for environments where exposure to chemicals is frequent, such as industrial facilities, laboratories, and agricultural buildings. However, it is essential to consider that the extent of chemical resistance may vary based on the specific resin formulation, as well as the concentration and duration of exposure to chemicals. Therefore, it is recommended to consult the manufacturer or supplier of the FRP panels to ensure their compatibility with the specific chemicals and conditions relevant to your application.

- Q: Can FRP roofing panels be used for skylights in healthcare facilities?

- Yes, FRP roofing panels can be used for skylights in healthcare facilities. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, lightweight nature, and ability to transmit natural light. These qualities make them a suitable choice for skylights in healthcare facilities, as they provide ample natural light while maintaining a secure and safe environment. Additionally, FRP panels offer UV protection, impact resistance, and are easy to clean, making them a practical option for healthcare settings.

Send your message to us

Frp Roof Panels Southerland - Fiber Reinforce Plastic Sheet Panel with 1.5 mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords