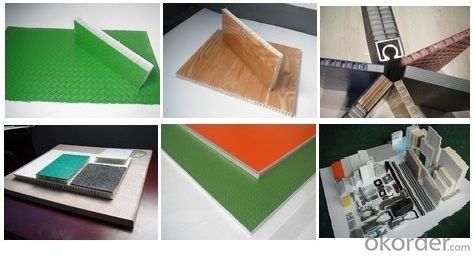

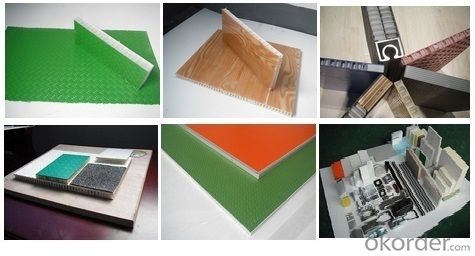

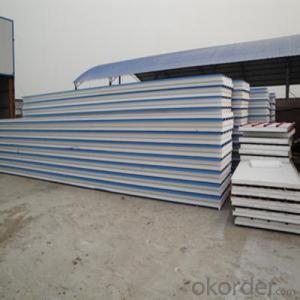

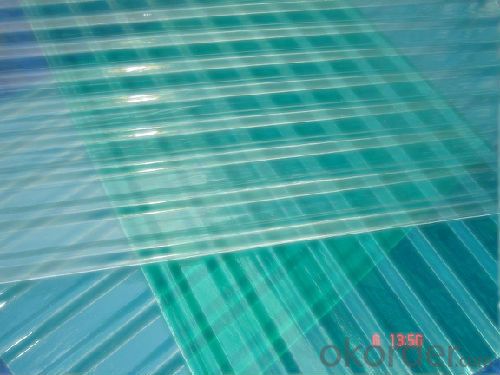

Corrugated FRP Fiber Reinforce Plastic Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Corrosion resistance

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2. Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

3. Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

4. Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

5. Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

6.Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

Specification:

Sandwich including PU、XPS、Polywood and PP Honeycomb ect.

Item | Unit | Parameter |

Thickness | mm | 5mm ~200mm |

Width | mm | <3000mm |

Length | m | <15m |

Heat transfer coefficient | Kol/m2 | 0.57 ~ 0.117(T50-100mm) |

- Q: Can FRP roofing panels be used in areas with high levels of industrial emissions?

- Yes, FRP roofing panels can be used in areas with high levels of industrial emissions. FRP (Fiberglass Reinforced Plastic) panels are known for their durability and resistance to corrosion, making them suitable for harsh environments such as those with high industrial emissions. They are designed to withstand chemical exposure, UV radiation, and temperature variations, making them a reliable choice for areas with heavy pollutants. However, it is still important to consider the specific emissions and consult with manufacturers to ensure that the FRP panels meet the required standards and can withstand the specific conditions of the industrial emissions in the area.

- Q: Are FRP roofing panels suitable for recreational areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for recreational areas. FRP roofing panels are known for their durability and resistance to various weather conditions, making them ideal for outdoor spaces. They are highly resistant to UV rays, which helps prevent fading and damage from sunlight exposure. Additionally, FRP panels are lightweight and easy to install, making them a cost-effective option for recreational areas. FRP roofing panels also offer excellent insulation properties, providing a comfortable and controlled environment in recreational spaces. They can withstand high heat, extreme cold, and are resistant to corrosion, making them suitable for areas with high moisture levels such as swimming pool enclosures or outdoor play areas. Furthermore, FRP roofing panels are available in a variety of colors and designs, allowing for customization and aesthetic appeal in recreational areas. They can be easily cleaned and maintained, ensuring a long-lasting and visually pleasing roof for years to come. However, it is important to note that the suitability of FRP roofing panels for recreational areas may vary depending on the specific requirements and intended use of the space. It is recommended to consult with a professional roofing contractor or engineer to determine the best roofing material for your specific recreational area.

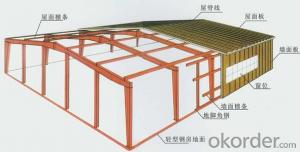

- Q: Can FRP roofing panels be installed on top of purlins or rafters?

- FRP roofing panels can be easily installed on top of purlins or rafters, which is a commonly used method for FRP roofing systems. The purlins or rafters play a crucial role in providing the necessary support and structure for the panels, ensuring their stability and durability. To ensure a successful installation, it is important to properly space and align the purlins or rafters according to the size and weight of the FRP roofing panels. Additionally, it is crucial to follow proper fastening techniques to securely attach the panels to the purlins or rafters, guaranteeing a long-lasting and secure installation. All in all, this method of installing FRP roofing panels on top of purlins or rafters is a dependable and efficient way to create a strong and functional roofing system.

- Q: Can FRP roofing panels be customized in terms of color and design?

- Yes, FRP roofing panels can be customized in terms of color and design. They can be manufactured in various colors and patterns to suit different aesthetic preferences and architectural requirements.

- Q: Do FRP roofing panels require special installation techniques?

- Special installation techniques are necessary for FRP (Fiberglass Reinforced Plastic) roofing panels. Unlike traditional roofing materials such as asphalt shingles or metal sheets, FRP panels have distinct qualities that require specific handling and installation methods. Firstly, FRP panels are both lightweight and delicate, requiring careful handling during installation to prevent breakage. To avoid cracking or shattering the panels, it is important to take precautions and not drop or mishandle them. Using proper lifting and support equipment is also crucial to prevent damage and ensure a safe installation. Secondly, FRP panels expand and contract with temperature changes, so it is important to account for these movements during installation. Following manufacturer guidelines regarding panel spacing and fastening methods is necessary to allow for thermal expansion and contraction. Failure to do so can result in buckling, warping, or premature failure of the roofing system. Moreover, FRP roofing panels should only be installed on a structurally sound and well-prepared substrate. The substrate must be clean, dry, and flat to ensure proper adhesion and avoid any potential issues that may compromise the integrity of the roofing system. Lastly, it is essential to properly seal and flash the joints and edges of FRP panels to prevent water infiltration and ensure a watertight installation. This may involve using specific sealants or adhesives recommended by the manufacturer to maintain the durability and longevity of the roofing system. In conclusion, due to their unique characteristics, FRP roofing panels require special installation techniques. Following manufacturer guidelines and recommendations is crucial to achieve a safe and successful installation that maximizes the performance and lifespan of the FRP roofing system.

- Q: Can FRP roofing panels be installed on steel structures?

- Yes, FRP roofing panels can be installed on steel structures. FRP (Fiberglass Reinforced Plastic) roofing panels are versatile and can be easily installed on various types of structures, including steel. The panels are lightweight, durable, and provide excellent resistance to corrosion and weathering. They can be securely attached to steel structures using appropriate fasteners and installation methods.

- Q: Are FRP roofing panels prone to fading or discoloration?

- FRP (Fiber Reinforced Plastic) roofing panels are generally resistant to fading and discoloration. The panels are designed to withstand UV exposure and are often coated with protective layers that prevent color fading over time. However, it is important to note that prolonged exposure to harsh sunlight and extreme weather conditions can still cause some level of fading or discoloration over an extended period. Regular maintenance and proper care, such as cleaning and applying protective coatings, can help minimize any potential fading or discoloration. Overall, FRP roofing panels are known for their durability and resistance to fading, making them a reliable choice for long-lasting roofing solutions.

- Q: Can FRP roofing panels be used in historical preservation projects?

- Yes, FRP roofing panels can be used in historical preservation projects. These panels are lightweight, durable, and resistant to corrosion, making them suitable for protecting historical buildings while maintaining their original aesthetic. Additionally, FRP panels can be customized to mimic the appearance of traditional roofing materials, ensuring a seamless integration with the historical architecture.

- Q: Are FRP roofing panels resistant to chemical fumes or gases?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are generally resistant to chemical fumes or gases. The inherent properties of FRP, such as its non-reactive nature and high resistance to corrosion, make it an ideal choice for environments where chemical exposure is a concern. However, the specific resistance of FRP roofing panels to certain chemicals may vary, and it is recommended to consult with the manufacturer or supplier for detailed information on chemical compatibility.

- Q: Can FRP roofing panels be used for skylights in healthcare facilities?

- Yes, FRP roofing panels can be used for skylights in healthcare facilities. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, lightweight nature, and ability to transmit natural light. These qualities make them a suitable choice for skylights in healthcare facilities, as they provide ample natural light while maintaining a secure and safe environment. Additionally, FRP panels offer UV protection, impact resistance, and are easy to clean, making them a practical option for healthcare settings.

Send your message to us

Corrugated FRP Fiber Reinforce Plastic Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords