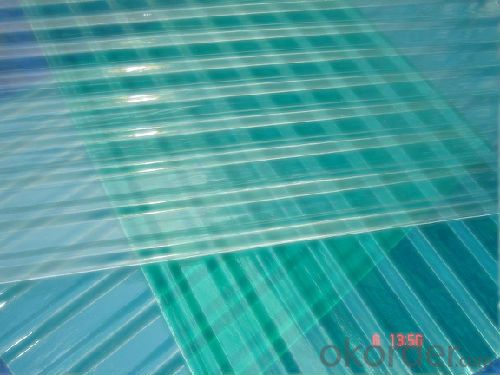

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2.Characteristics

Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

3.Application

Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: Are FRP roofing panels resistant to damage from chemicals or pollutants?

- FRP roofing panels demonstrate remarkable resilience against chemicals and pollutants, rendering them highly resistant to damage. These panels are crafted by combining fiberglass with plastic resin, resulting in exceptional protection against corrosion, chemical exposure, and various environmental contaminants. This outstanding resistance makes FRP roofing panels an optimal choice for industries or settings where chemical spills, fumes, or other harmful substances may come into contact with the roof. Furthermore, FRP roofing panels boast UV resistance, enabling them to endure prolonged exposure to sunlight without deterioration or compromising their structural integrity. Overall, FRP roofing panels offer a robust and enduring solution that effectively withstands the corrosive effects of chemicals and pollutants, ensuring the roof's protection and longevity.

- Q: Are FRP roofing panels resistant to mold and mildew?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to mold and mildew. The inherent properties of FRP, such as its non-porous surface and resistance to moisture, make it an ideal material for preventing the growth of mold and mildew on roofing panels.

- Q: Are FRP roofing panels resistant to fading?

- Yes, FRP roofing panels are resistant to fading.

- Q: Can FRP roofing panels be used for zoos?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for zoos. FRP roofing panels are known for their durability, strength, and resistance to various environmental elements, making them suitable for a wide range of applications, including zoos. In zoos, where the safety and wellbeing of animals is of utmost importance, FRP roofing panels offer several advantages. Firstly, they are lightweight yet sturdy, providing a secure and reliable roofing solution. This is particularly important in areas where heavy snow loads or strong winds may be a concern. Secondly, FRP panels have excellent resistance to UV radiation, which means they are highly resistant to fading, discoloration, or degradation caused by prolonged exposure to the sun. This is crucial for maintaining the aesthetics of the zoo and ensuring that the animals are housed in visually appealing enclosures. Additionally, FRP roofing panels have low thermal conductivity, which helps regulate the temperature inside the enclosures. This is beneficial for the animals, as it allows for a more comfortable and controlled environment. FRP panels also have excellent insulation properties, which can contribute to energy efficiency and reduce heating or cooling costs. Furthermore, FRP roofing panels are available in a variety of colors, textures, and designs, allowing zoo designers to create visually appealing enclosures that mimic natural habitats. This can enhance the overall experience for visitors while providing a more stimulating and enriching environment for the animals. Overall, FRP roofing panels offer a versatile and reliable roofing solution for zoos. Their durability, resistance to environmental factors, and aesthetic options make them a suitable choice for creating safe and visually appealing enclosures for animals.

- Q: Can FRP roofing panels be used in wastewater treatment plants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in wastewater treatment plants. FRP panels are known for their excellent corrosion resistance, durability, and low maintenance requirements, making them a suitable choice for such harsh environments. Additionally, FRP panels are lightweight, easy to install, and can be customized to fit specific project requirements. They also provide superior resistance to chemicals, UV rays, and weathering, ensuring long-term performance and cost-effectiveness. Overall, FRP roofing panels are a reliable option for wastewater treatment plants due to their ability to withstand corrosive conditions while providing a strong and durable roofing solution.

- Q: Are FRP roofing panels suitable for restaurants or food establishments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for restaurants or food establishments. FRP roofing panels are a popular choice for these types of establishments due to their numerous beneficial qualities. Firstly, FRP panels are highly durable and long-lasting. They are resistant to corrosion, rot, and mold, making them ideal for environments that may have exposure to moisture or humidity, such as commercial kitchens or food processing areas. This ensures that the panels will maintain their structural integrity and appearance over time, minimizing the need for frequent repairs or replacements. Additionally, FRP roofing panels are lightweight yet strong, making them easy to install and handle. This can be especially advantageous for restaurants or food establishments that require quick installation or renovations. The lightweight nature of the panels also reduces the strain on the building's structure, which can be a significant factor in older or existing establishments. Furthermore, FRP panels offer excellent insulation properties. They can help maintain a comfortable indoor temperature by preventing heat loss or gain, which is particularly important in food establishments where temperature control is crucial for food safety and operational efficiency. Moreover, FRP panels are available in a wide range of colors, finishes, and designs, allowing for customization that suits the aesthetic requirements of restaurants or food establishments. This versatility allows for the creation of visually appealing spaces that align with the brand identity or theme of the establishment. Lastly, FRP panels are relatively low maintenance and easy to clean. Their smooth, non-porous surface prevents the buildup of dirt, grease, or food particles, reducing the risk of bacterial growth or contamination. Regular cleaning with mild detergents or sanitizers is usually sufficient to maintain their cleanliness and hygiene standards. Overall, FRP roofing panels are a suitable choice for restaurants or food establishments due to their durability, resistance to moisture, ease of installation, insulation properties, customization options, and low maintenance requirements.

- Q: Can FRP roofing panels be used in airports or transportation hubs?

- Yes, FRP roofing panels can be used in airports or transportation hubs. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion and UV exposure. These qualities make them suitable for use in high-traffic areas like airports and transportation hubs where durability, ease of installation, and low maintenance are important factors. Additionally, FRP panels can provide excellent insulation and are fire-resistant, making them a safe and efficient choice for such facilities.

- Q: Can FRP roofing panels be used for covered outdoor fitness areas or gyms?

- Yes, FRP roofing panels can be used for covered outdoor fitness areas or gyms. FRP (Fiber Reinforced Plastic) roofing panels are known for their durability, weather resistance, and ability to withstand harsh conditions. They are resistant to corrosion, UV rays, and moisture, making them suitable for outdoor applications. Additionally, FRP panels offer excellent light transmission, allowing natural light to enter the covered area, creating an inviting and well-lit space for fitness activities.

- Q: Are FRP roofing panels easy to clean?

- Yes, FRP roofing panels are generally easy to clean. FRP stands for Fiberglass Reinforced Plastic, which is a durable and low-maintenance material. These panels have a smooth surface that resists the accumulation of dirt, dust, and other debris. Cleaning them usually involves simple steps such as rinsing with water and using a mild detergent if necessary. Additionally, FRP roofing panels are not prone to staining or discoloration, making them relatively hassle-free when it comes to maintenance. However, it is always recommended to follow the manufacturer's cleaning instructions for optimal results.

- Q: Can FRP roofing panels be used for convention centers?

- Convention centers can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. There are several advantages associated with FRP panels that make them appropriate for such purposes. To begin with, FRP panels possess a unique combination of being lightweight yet exceptionally strong. This characteristic renders them ideal for large-scale structures like convention centers. They can span considerable distances without requiring additional support structures, thus minimizing construction costs and enabling more flexible design possibilities. Moreover, FRP panels exhibit high resistance to corrosion, weathering, and UV radiation. Consequently, the roofing system remains durable and maintains its appearance over time, even in harsh outdoor environments. Additionally, FRP panels can be manufactured with excellent fire resistance properties, which are essential in ensuring the safety of individuals in extensive public spaces such as convention centers. Furthermore, FRP roofing panels offer exceptional thermal insulation properties, contributing to the regulation of indoor temperatures. This, in turn, leads to energy savings and enhanced comfort for the occupants. Lastly, FRP panels are available in an extensive array of colors, finishes, and profiles. This versatility allows for customization and aesthetic integration with the overall design of the convention center. In conclusion, due to their strength, durability, fire resistance, thermal insulation properties, and design flexibility, FRP roofing panels prove to be a suitable choice for convention centers.

Send your message to us

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords