FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

1.corrosion resistance no rust, no maintenance, long service life.

2.lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%), the one way than intensity and stiffness is quite prominent, the density of glass fiber reinforced plastic is only about a quarter of the steel, light weight, very easy to handle, so as to reduce the handling fee.

3..Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

4.anti-aging select highquality FRP pultrusion profiles, the service life of the product can reach more than 20 years, and in all the pultrusion FRP profiles were added in the formula of an-uv agent in order to get the best anti-uv effect.

5.excellent electromagnetic performance it has excellent electrical insulation, electrical, magnetic and electric spark can be used in risk conduction,

sensitive to magnetic equipment area, and flammable and explosive place.

SPECIFICATION

| Product Details | |

| Brand | CMAX |

| Model NO. | BQ-1111 |

| Color | Any Pantone color or multi-colors can be customized. |

| Size | Length: any length you want |

| width: 660mm | |

| thickness: 3mm | |

| surface | glossy |

| MOQ: | 50 meter |

| Payment Term: | TT(Telegraphic Transfer),L/C(letter of credit), Paypal, western union, HSBC Hong Kong. |

| Production Capacity: | 70000pcs Per week |

| Shipping | DHL,FEDEX |

| Additional term | 1. Any customized shape and size are available. 2. If necessary,we will provide some professional suggestion for your reference. |

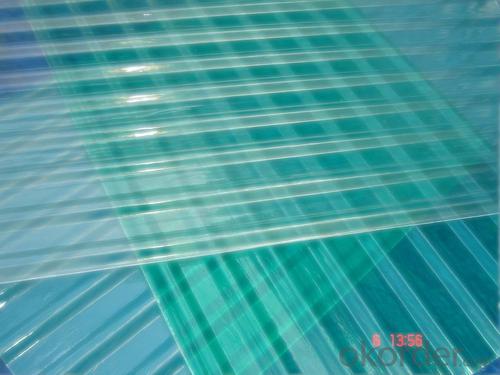

PICTURES

- Q: Are FRP roofing panels suitable for use in agricultural buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for use in agricultural buildings. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for agricultural applications. Additionally, FRP panels offer good insulation properties, allowing for temperature control and energy efficiency in agricultural structures.

- Q: Do FRP roofing panels require any specific safety measures during installation?

- During the installation of FRP roofing panels, specific safety measures are required. Take note of the following important safety precautions: 1. Personal Protective Equipment (PPE): It is necessary for installers to wear appropriate safety gear such as safety glasses, gloves, and non-slip footwear. This will safeguard them against potential hazards like sharp edges or falling debris. 2. Ensuring a Safe Work Environment: Prior to commencing the installation, make sure the work area is free from any obstructions or tripping hazards. Maintaining good housekeeping practices is crucial to minimize the risk of accidents. 3. Fall Protection: If the installation involves working at heights, implement fall protection measures such as harnesses, guardrails, or safety nets. Installers should receive proper training on the use of fall protection equipment. 4. Proper Lifting Techniques: FRP roofing panels can be heavy, so it is important to use proper lifting techniques to prevent strains or injuries. Depending on the weight and size of the panels, team lifting or mechanical lifting devices may be necessary. 5. Power and Tool Safety: If power tools are used during installation, ensure that they are operated according to the manufacturer's instructions and only by trained personnel. Adhere to electrical safety precautions such as using grounded tools and avoiding wet conditions. 6. Weather Conditions: Weather conditions can affect the safety of the installation, particularly when working at heights. Installers should be mindful of potential hazards like strong winds, rain, or lightning and take appropriate precautions, including rescheduling the work if necessary. 7. Training and Supervision: Proper training in the installation techniques and safety measures specific to FRP roofing panels is essential for all installers. Regular supervision and communication regarding safety practices can prevent accidents and maintain a safe working environment. By adhering to these safety measures, the risk of accidents or injuries during the installation of FRP roofing panels can be significantly reduced, ensuring the safety of the installers and the overall success of the project.

- Q: Do FRP roofing panels require specific ventilation systems?

- No, FRP roofing panels do not require specific ventilation systems. However, adequate ventilation is important for any roofing system to prevent moisture buildup and ensure proper air circulation, which can help extend the lifespan of the roof.

- Q: Can FRP roofing panels be customized in terms of color and design?

- Indeed, when it comes to color and design, FRP (Fiberglass Reinforced Plastic) roofing panels offer great customization options. They can be produced in a plethora of colors, catering to personal preferences and meeting the aesthetic demands of diverse projects. Moreover, FRP panels can incorporate a range of patterns, textures, and finishes, enabling the attainment of specific visual effects. This level of customization enhances architectural design possibilities, rendering FRP roofing panels highly sought after in both residential and commercial settings.

- Q: Do FRP roofing panels require frequent maintenance?

- No, FRP roofing panels do not require frequent maintenance. They are highly durable and resistant to damage, which reduces the need for regular maintenance. However, occasional cleaning and inspection to remove debris or check for any potential issues is recommended to ensure their longevity and optimal performance.

- Q: Are FRP roofing panels easy to repair?

- Repairing FRP roofing panels is relatively easy. The lightweight and durable nature of these panels makes them easy to handle and work with during the repair process. They are also resistant to corrosion, mold, and mildew, reducing the need for extensive repair. To repair FRP roofing panels, the damaged area needs to be cleaned, and any loose material or debris should be removed. Then, a suitable patching material or adhesive is applied to seal the damaged section. Depending on the extent of the damage and the individual's expertise, this can be done by a homeowner or a professional contractor. It's important to note that the ease of repair may vary depending on the specific type and brand of FRP panel used. Some manufacturers may offer repair kits or provide specific instructions for their products, which can simplify the repair process even more. Overall, with proper maintenance and timely repairs, FRP roofing panels can provide long-lasting protection for various applications.

- Q: Do FRP roofing panels have any specific insulation properties?

- Yes, FRP roofing panels do have specific insulation properties. They have low thermal conductivity, which helps to prevent heat transfer and maintain a more comfortable temperature inside the building. Additionally, FRP panels can be designed with added insulation layers to further enhance their thermal insulation capabilities.

- Q: Can FRP roofing panels be used for sports stadiums or arenas?

- Yes, FRP roofing panels can be used for sports stadiums or arenas. FRP (Fiber Reinforced Plastic) roofing panels are known for their durability, lightweight nature, and resistance to various weather conditions. These qualities make them suitable for use in sports stadiums or arenas where large spans of roofing are required. Additionally, FRP panels can be easily installed and maintained, making them a practical choice for such structures.

- Q: Are FRP roofing panels compatible with different roofing fasteners?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are compatible with various roofing fasteners. These panels are versatile and can be easily installed using a range of fastening methods, depending on the specific application and building requirements. Some common fastening options for FRP roofing panels include screws, nails, clips, or adhesive systems. When selecting roofing fasteners for FRP panels, it is important to consider factors such as the panel thickness, the type of substrate or roof deck, the expected wind uplift loads, and any specific building codes or regulations. The manufacturer's guidelines and recommendations should also be followed to ensure proper installation and long-term durability. Overall, FRP roofing panels offer flexibility in terms of fastener compatibility, allowing for various installation methods to meet different project needs.

- Q: Are FRP roofing panels compatible with different types of flashing systems?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are compatible with different types of flashing systems. FRP panels are versatile and can be used in various roofing applications, including commercial, industrial, and residential buildings. They can be easily integrated with different types of flashing systems, such as metal, PVC, or rubber flashings. Proper installation techniques and compatible flashing materials should be used to ensure a watertight and secure connection between the FRP panels and the flashing system. It is recommended to consult with a professional roofing contractor or manufacturer for specific recommendations and guidelines on the compatibility of FRP roofing panels with different types of flashing systems.

Send your message to us

FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords