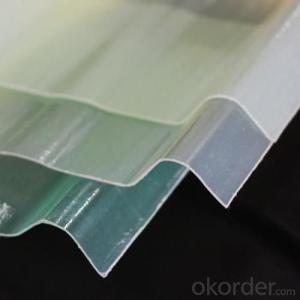

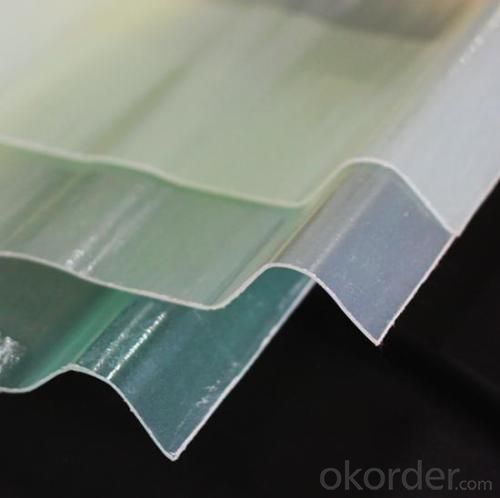

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

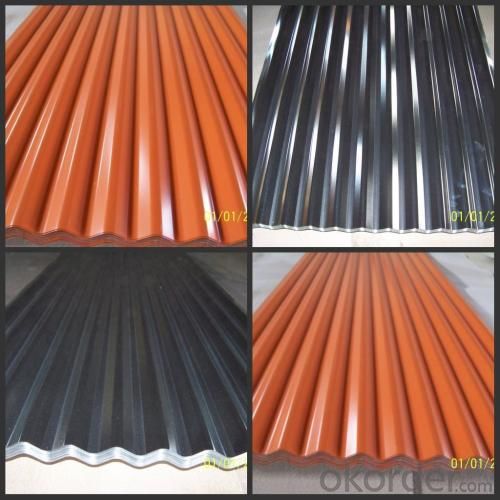

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Can FRP roofing panels be used for zoos?

- Zoos can utilize FRP roofing panels due to their durability, strength, and resistance to environmental elements. These panels are suitable for various applications, including zoos, where animal safety is paramount. When it comes to zoos, the use of FRP roofing panels brings several advantages. Firstly, they are lightweight yet robust, ensuring a secure and dependable roofing solution, especially in areas prone to heavy snow loads or strong winds. Secondly, FRP panels possess exceptional resistance against UV radiation, preventing fading, discoloration, or degradation caused by prolonged sun exposure. This is vital for maintaining the zoo's aesthetics and ensuring visually pleasing enclosures for the animals. Furthermore, FRP roofing panels exhibit low thermal conductivity, which aids in regulating the temperature within the enclosures. This contributes to a more comfortable and controlled environment for the animals. Additionally, these panels provide excellent insulation, resulting in energy efficiency and reduced heating or cooling costs. Moreover, FRP roofing panels offer a wide range of colors, textures, and designs, enabling zoo designers to create visually appealing enclosures that mimic natural habitats. This enhances the overall experience for visitors while providing a more stimulating and enriching environment for the animals. In conclusion, FRP roofing panels serve as a versatile and reliable roofing solution for zoos. Their durability, resistance to environmental factors, and aesthetic options make them a suitable choice for creating safe and visually appealing enclosures for animals.

- Q: Can FRP roofing panels be used in mobile homes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in mobile homes. These panels are lightweight, durable, and resistant to extreme weather conditions, making them a suitable choice for mobile homes. Additionally, FRP roofing panels provide superior insulation and are easy to install, making them an efficient and cost-effective roofing option for mobile homes.

- Q: Are FRP roofing panels prone to cracking or warping?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally known for their durability and resistance to cracking or warping. These panels are made with a combination of fiberglass and plastic, which provides them with excellent strength and structural integrity. Compared to other roofing materials such as wood or metal, FRP panels have a relatively low coefficient of expansion. This means that they expand and contract less with temperature changes, reducing the chances of cracking or warping. Additionally, the fiberglass reinforcement in FRP panels adds extra strength and stiffness, making them less susceptible to damage from impacts or heavy loads. This makes them a popular choice in industrial and commercial settings, where durability is a key requirement. However, it's important to note that the quality of FRP panels can vary depending on the manufacturer and the specific production process. Low-quality panels or panels that are not properly installed may be more prone to cracking or warping. Therefore, it is crucial to choose a reputable manufacturer and ensure proper installation to maximize the longevity and performance of FRP roofing panels.

- Q: Are FRP roofing panels suitable for healthcare facilities or hospitals?

- Yes, FRP roofing panels are suitable for healthcare facilities or hospitals. FRP panels are known for their durability, resistance to chemicals, and ability to withstand harsh weather conditions. These qualities make them an excellent choice for healthcare facilities that require a reliable and long-lasting roofing solution. Additionally, FRP panels are lightweight, easy to install, and low maintenance, which can be advantageous for hospitals that need a roofing material that is cost-effective and easy to manage.

- Q: Aluminum plate Eterpan lighting plate are used in what place

- But Eterpan is the fiber cement board can do LOFT sandwich.The personal use of lighting boards is less extensive!

- Q: Can FRP roofing panels be used for wall cladding as well?

- Yes, FRP roofing panels can be used for wall cladding as well. FRP stands for Fiber Reinforced Plastic, which is a strong and durable material that is commonly used for roofing due to its weather resistance and low maintenance requirements. However, it can also be utilized as wall cladding because of its lightweight nature and ability to withstand external elements. FRP panels offer excellent insulation properties, making them suitable for both roofing and wall applications. They are available in a variety of colors, finishes, and profiles, allowing for creative design options. Whether used for roofing or wall cladding, FRP panels provide a cost-effective and long-lasting solution for any building project.

- Q: Are FRP roofing panels suitable for coastal areas with salt spray?

- Coastal areas with salt spray can benefit from the use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess a unique composition that grants them a high level of resistance against corrosion and damage caused by exposure to saltwater. They are specifically designed to endure harsh environmental conditions, including the corrosive effects of salt spray. The addition of fiberglass reinforcement in FRP panels enhances their strength and durability, allowing them to withstand the strong winds and extreme weather conditions often encountered in coastal areas. Moreover, FRP panels exhibit exceptional UV resistance, safeguarding them against fading or deterioration when continuously exposed to sunlight. In addition to their resistance and durability, FRP roofing panels are renowned for their lightweight nature, enabling easy transportation and installation. This characteristic proves particularly advantageous in coastal areas where geographical constraints can present challenges during transportation and installation processes. Ultimately, FRP roofing panels offer a suitable option for coastal areas with salt spray due to their ability to resist corrosion, their durability, their UV resistance, and their lightweight nature. However, it is always advisable to consult a professional who can evaluate specific environmental factors and determine the optimal roofing solution for your coastal area.

- Q: Can FRP roofing panels be used for outdoor structures?

- Outdoor structures can indeed utilize FRP (Fiber Reinforced Plastic) roofing panels. Renowned for their sturdiness, robustness, and ability to withstand diverse weather elements like UV rays, rain, and wind, FRP roofing panels are specifically engineered to endure challenging outdoor conditions, ensuring exceptional safeguarding for various structures. They are frequently employed in outdoor settings, including patios, pergolas, carports, sheds, and agricultural buildings. Apart from their exceptional resistance to weather, FRP roofing panels possess the advantages of being lightweight, easy to install, and having a long lifespan. All in all, FRP roofing panels present a dependable and pragmatic choice for outdoor structures.

- Q: Can FRP roofing panels be used for patio covers or outdoor kitchens?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for patio covers or outdoor kitchens. FRP panels are lightweight, durable, and resistant to weathering, making them a suitable choice for outdoor applications. They provide excellent protection against UV rays, rain, and hail, ensuring that your patio cover or outdoor kitchen remains well-protected from the elements. Additionally, FRP panels are easy to install and maintain, making them a convenient option for these purposes.

- Q: Are FRP roofing panels resistant to chemical exposure?

- Yes, FRP roofing panels are generally resistant to chemical exposure. Due to their composition and design, FRP panels are highly durable and can withstand exposure to various chemicals without significant damage or degradation. However, the specific resistance may vary depending on the type and concentration of the chemical involved.

Send your message to us

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords