Corrugated Plastic Roofing Sheet, Fiber FRP Transparent Roof Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP Roofing Sheet are widely used in the field of industrial plants, warehouses, greenhouses, stations, docks, airports, sports buildings, commercial buildings, steel structures and other lighting areas. FRP is glass fiber and one or several thermosetting or thermoplastic resin composite material, such as phenolic resin, epoxy resin, polyester resin, polyimide resin. Glass fiber reinforced glass fiber that is the early 20th century, the development of a new composite material, it has a light weight, high strength, corrosion, insulation, insulation, noise and many other advantages.

FEATURES

1. Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance;

2. Low thermal conductivity & good insulation performance;

3. Non-toxic, non-asbestos, etc., in line with world health standards;

4. No moss & prevent microbial growth;

5. High impact and resistant to strong wind;

6. Safe and reliable, Not combustion-supporting in open fire;

7. Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

Material | FRP, ASA, PVC | ||

Thickness | 1.0mm - 3.0mm | ||

Color | Clear, milk white, blue, green, red | ||

Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

Shelf life | 15 years | ||

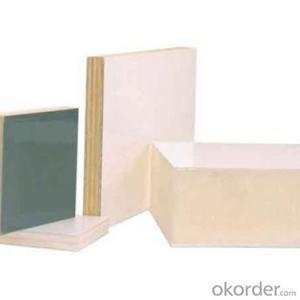

PICTURES

- Q:Can FRP roofing panels be used for covered walkways in shopping malls or retail centers?

- Covered walkways in shopping malls or retail centers can indeed utilize FRP roofing panels. FRP roofing panels, also known as Fiberglass Reinforced Plastic, boast durability, lightweight characteristics, and resilience to various weather conditions. These attributes make them ideal for shielding against rain, snow, and sunlight. Furthermore, the installation and maintenance of FRP roofing panels are hassle-free, which benefits shopping malls or retail centers seeking swift and efficient construction or renovation projects. Additionally, FRP panels can be tailored to meet the specific design and aesthetic requirements of the shopping mall or retail center. Moreover, in comparison to other roofing materials, FRP roofing panels provide a cost-effective solution. Their extended lifespan diminishes the need for frequent replacements or repairs, ultimately resulting in long-term savings. To sum up, FRP roofing panels present a viable choice for covered walkways in shopping malls or retail centers due to their sturdiness, weather resistance, easy installation, customization options, and economical nature.

- Q:Can FRP roofing panels be used in shopping malls or retail centers?

- FRP roofing panels are perfectly suitable for shopping malls or retail centers. These panels are renowned for their durability, versatility, and resistance against corrosion, which makes them ideal for various commercial applications. Moreover, their lightweight nature facilitates easy and cost-effective installation. In addition, FRP roofing panels come in a wide array of colors and finishes, allowing seamless integration with the design and aesthetic of shopping malls or retail centers. These panels also boast excellent natural light transmission, minimizing the need for artificial lighting during daylight hours and potentially reducing energy expenses. In summary, FRP roofing panels are an excellent choice for shopping malls or retail centers due to their durability, versatility, and aesthetic appeal.

- Q:Can FRP roofing panels be used in zoos or animal enclosures?

- Yes, FRP roofing panels can be used in zoos or animal enclosures. These panels are known for their durability, resistance to corrosion, and ability to withstand harsh environmental conditions. They can provide excellent protection for animals from sun, rain, and other elements, making them a suitable choice for roofing in zoos or animal enclosures.

- Q:Can FRP roofing panels be used for agricultural structures?

- Agricultural structures can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Due to their durability, strength, and ability to withstand different environmental factors, FRP panels have become a popular choice for agricultural buildings. These panels are lightweight, allowing for easy installation and handling, while still maintaining exceptional structural integrity. In terms of weather resistance, FRP roofing panels are specifically designed to endure extreme conditions such as strong winds, heavy snow loads, and intense sunlight. Additionally, they are resistant to corrosion, rot, and pests, making them well-suited for agricultural structures that may encounter moisture or harsh chemicals. Moreover, FRP roofing panels provide excellent insulation, ensuring a comfortable temperature within agricultural buildings. This is particularly beneficial for structures like greenhouses, where maintaining the right temperature is crucial for successful plant growth. In summary, FRP roofing panels offer a cost-effective and long-lasting solution for agricultural structures. They provide the necessary protection and durability required for a range of farming applications, including barns, storage sheds, poultry houses, and more.

- Q:Are FRP roofing panels resistant to chemical fumes?

- Yes, FRP roofing panels are generally resistant to chemical fumes. The fiberglass reinforced plastic used in their construction provides excellent resistance to a wide range of chemical substances, making them a suitable choice for environments where chemical fumes may be present. However, it is always recommended to consult the manufacturer's specifications and guidelines for specific chemical resistance information.

- Q:Are FRP roofing panels suitable for areas with heavy snowfall?

- FRP roofing panels are indeed a suitable choice for regions experiencing frequent heavy snowfall. These panels possess exceptional durability and are capable of enduring substantial snow loads without any signs of cracking or breaking. Their structural integrity is commendable, specifically designed to withstand the weight of accumulated snow. Furthermore, these panels feature a sleek surface that facilitates the smooth sliding of snow, effectively minimizing the possibility of snow accumulation and subsequent structural harm. Nevertheless, it remains imperative to guarantee precise installation and regular maintenance to guarantee the longevity and optimal functionality of FRP roofing panels in areas prone to heavy snowfall.

- Q:Do FRP roofing panels require any specific safety measures during installation?

- Yes, FRP roofing panels do require specific safety measures during installation. These measures typically include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats to protect against potential hazards. It is also important to ensure proper ventilation during installation to minimize exposure to potentially harmful fumes. Additionally, following manufacturer guidelines and using proper lifting techniques when handling the panels is crucial to prevent injuries.

- Q:Can FRP roofing panels be used for covered parking structures or garages?

- Yes, FRP roofing panels can be used for covered parking structures or garages. FRP panels are known for their durability, resistance to weathering, and ability to withstand heavy loads. They are also lightweight, making them a suitable choice for such structures. Additionally, FRP panels can provide UV protection, which is essential for parking areas exposed to sunlight. Overall, FRP roofing panels are a reliable option for covered parking structures or garages.

- Q:Can FRP roofing panels be installed on both residential and commercial parking garages?

- Yes, FRP roofing panels can be installed on both residential and commercial parking garages. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and have excellent resistance to corrosion, making them suitable for a wide range of applications including parking garages. They offer high strength and are resistant to weathering, UV radiation, and chemicals, making them ideal for protecting parking structures from environmental damages. Additionally, FRP panels can be easily installed and maintained, making them a cost-effective roofing option for both residential and commercial parking garages.

- Q:Are FRP roofing panels suitable for industrial buildings?

- Indeed, industrial buildings can benefit from the suitability of FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, strength, and ability to withstand diverse weather conditions, these panels are an ideal choice for industrial structures. Not only are they lightweight, but they also possess a robustness that facilitates easy installation and reduces the burden on the structure. Moreover, FRP roofing panels possess excellent thermal insulation properties, thereby contributing to energy efficiency within industrial buildings. Furthermore, they exhibit resistance towards corrosion, chemicals, and UV radiation, guaranteeing a lengthy lifespan and minimal maintenance requirements. All in all, FRP roofing panels offer a reliable and cost-effective solution for industrial buildings, ensuring durability, weather resistance, and energy efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Plastic Roofing Sheet, Fiber FRP Transparent Roof Pane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords