Slag Pots for Steelmaking Production / Steel Slag Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The slag pots are cast steel slag pots, which are divided into 2.13m3, 4m3, 5m3, 9m3, 12m3, 16m3, 18m3, 20m3, 24m3 and other types of slag pots.

Slag pot weight: 5-75 tons

Use of slag pot: The slag pot is mainly used to carry converter steel slag desulfurization slag and large ladle casting residue of continuous casting.

Advantages of slag pot:

Rich production experience: more than 17 year experience with 1,000 pieces of slag pot production in various specifications and material requirements.

Long service life: Compared with the slag pot produced by molten steel from converter furnace, the service life is 2-3 times longer, and can reach more than 5,000 times

Strong technical strength:We adopt the domestic advanced "Huazhu CAE" casting simulation software to simulate thesolidification process of the slag pot. Then adjust it based on the simulation results, to ensure theoptimal process parameters. At the same time, we introduced the "Simcast" finite element simulationsoftware developed by "Aachen University of Germany" to verify the casting process parameter.

Advanced smelting process

Product quality optimization

5.1 The trunnion of the slag pot uses a high-heat insulation riser for feedingfocusing on ensuring the safety of the trunnion and the slag pot necklace. Internal quality, reducing cracks during use of the slag pot.

5.2 Ultrasonic flaw detection of 500MM range of slag pot trunnion.

5.3 The inner surface of the slag pot is finished, and the surface is smooth reaching Ra<100 ,which prevents the steel slag from sticking and causing failure in normal use and affecting the service life.

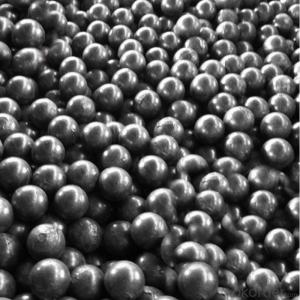

Pictures of Slag Pot

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: Is 316 casting better than 304 casting?

- It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

Send your message to us

Slag Pots for Steelmaking Production / Steel Slag Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches