Slag pot for metallurgy industry, for steel plant, olla de escoria

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

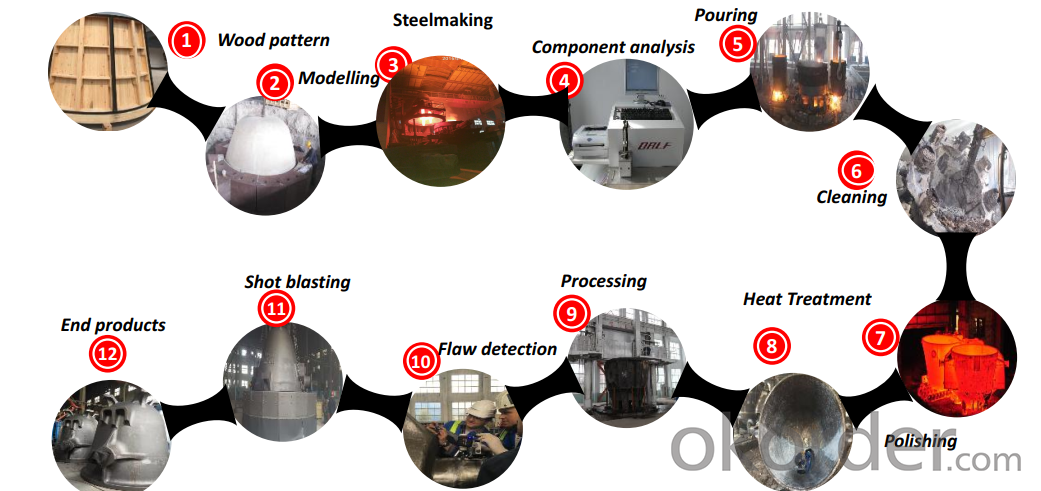

Slag pot is an important equipment for steelmaking in metallurgical industry. It is mainly used to carry converter slag, refining furnace slag and ladle residue of continuous casting.

Strength

More than 1000 slag pots were produced and deliver to customer with high satisfaction.

90% of slag pot were exported throughout the world. Our experience will guarantee the

high quality of products, which become our core competence and company’s intangible

resources

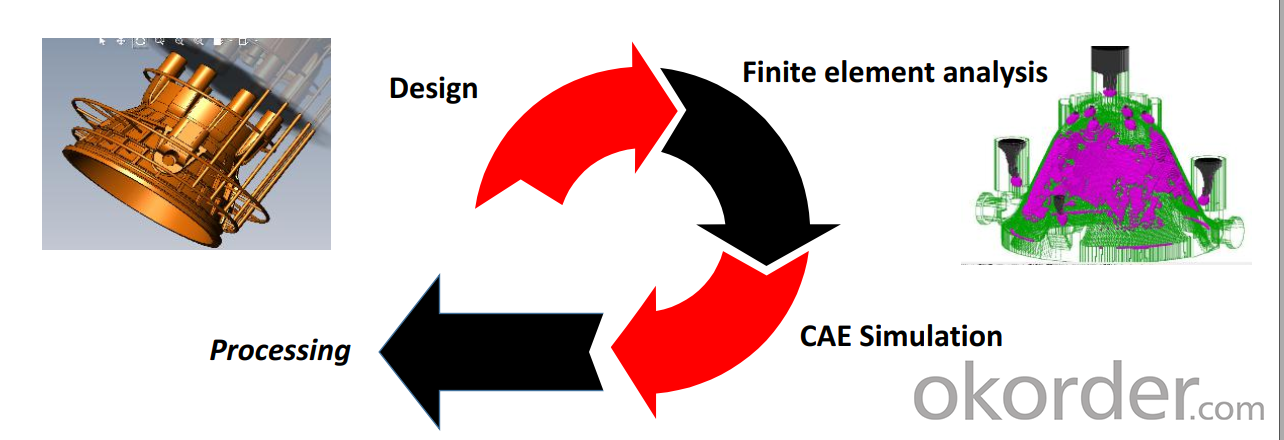

Combination of design and manufacture guarantee the continuous improvement which is

very helpful for the quality control.

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that integrates scientific research, manufacturing and logistics into one entity. CNBM is also the largest building materials and equipment specialists in China. Upon the State Council’s approval, CNBM owns more than 300 subordinate manufacturing factories and servicing companies till now. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many such of these fields, CNBM is playing a

leading role in the building industry in the country. CNBM International Corporation is the most important import

and export platform of CNBM group. With its advantages, CNBM International are mainly concentrate on Cement industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. Depending on the support of production divisions and its active staff, CNBM international reached a turnover of USD one billion in 2012. We will carry on the mutual beneficial, create value for our employees, share holders and clients and benefit the whole society in our future development.

Thanks you for your interest in our company products and

services. Your valuable comments are most welcome.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

Send your message to us

Slag pot for metallurgy industry, for steel plant, olla de escoria

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches