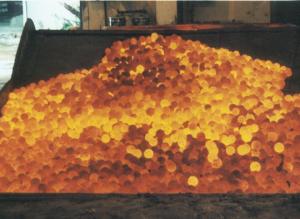

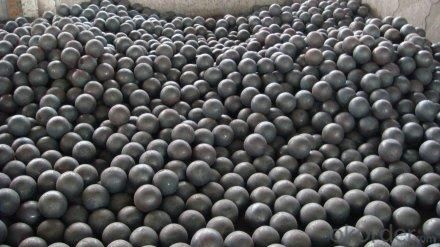

Precision High Chrome Casting Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chrome Steel Ball

We are a professional manufacturer which produce media ball.Our steel ball exported to

Chemcial Elements of Chrome Steel Ball

Name | C | Mn | Si | Cr | S | P |

50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

60MN | 0.57-.0.65 | 0.7-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

Specification and Hardness of Chrome Steel Ball

Name | Impact Test AK.J/cm2 | Endurance Test Times (5m) | Dia 25mm-60mm | Dia 70mm-100mm | ||

Surface | Core | Surface | Core | |||

50MN | ≥12 | ≥10000 | ≥56 | ≥50 | ≥55 | ≥50 |

60MN | ≥13 | ≥12000 | ≥58 | ≥52 | ≥58 | ≥50 |

65MN | ≥15 | ≥12000 | ≥62 | ≥54 | ≥58 | ≥52 |

B2 | ≥15 | ≥12000 | ≥62 | ≥55 | ≥58 | ≥52 |

Weigh of Chrome Steel Ball

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT |

20mm/0.75'' | +1,-0.5 | 0.033 | 30303 |

25mm/1'' | +1,-0.5 | 0.064 | 15625 |

30mm/1.25'' | +2.0,-1.0 | 0.11 | 9090 |

40mm/1.5'' | +2.0,-1.0 | 0.261 | 3831 |

50mm/2'' | +2.0,-1.0 | 0.510 | 1961 |

60mm/2.5'' | +2.0,-1.0 | 0.883 | 1132 |

70mm/2.75'' | +3.0,-1.5 | 1.402 | 713 |

80mm/3.25'' | +3.0,-1.5 | 2.092 | 478 |

90mm/3.5'' | +3.0,-1.5 | 2.98 | 335 |

100mm/4'' | +3.0,-1.5 | 4.087 | 244 |

110mm/4.5'' | +3.0,-1.5 | 5.44 | 183 |

120mm/4.75 | +3.0,-1.5 | 7.062 | 141 |

Applied fields of Chrome Steel Ball

a).Mines

b).Cement plant

c).Chemical Industries

Chrome Steel Ball Packing

Steel drum: 800-1000kgs;

Container bag: 1000kgs.

- Q: How to improve the surface roughness of casting parts?

- First, the accuracy of the model should be improved; two is to change the molding technique; the three is the coating; and the worker's technical level.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Aluminum alloy die-casting parts or casting box and other parts of the threaded hole, in the case of processing conditions, it is best to use wire tapping or machine tool processing! Direct casting is not advocated.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Cause of choking of casting parts

- Choke fire is the process of pouring a large number of gases can not be discharged smoothly, boiling in the metal liquid, resulting in a large number of castings in the pores, and even incomplete casting defects

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

1. Manufacturer Overview

| Location | Anhui, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 million |

| Main Markets | Mid East; Eastern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 50% |

| No.of Employees in Trade Department | 31-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Precision High Chrome Casting Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords