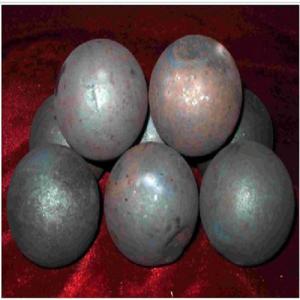

High Chrome Casting Balls for Mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information for High Chrome Casting Balls for Mining

CMAX high chrome casting balls for mining has good quality in the best price.

High Chrome Casting Balls

Chrome content:11-14%

Size: dia30-100mm

Hardness: dia30-70mm HRC58-63

dia80-100mm HRC57-62

Specifications of High Chrome Casting Balls for Mining

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Application of High Chrome Casting Balls for Mining

cement,metallury, mine,construction mateial and slurry

We are a professional manufacturer which produce media ball.Our steel ball exported to Chile,south Africa,Iran,Russia,USA etc.Nowadays,We have annual production capacity of 50,000 MT.

Chemcial Elements of Chrome Steel Ball

Specification and Hardness of Chrome Steel Ball

Weigh of Chrome Steel Ball

Chrome Steel Ball Packing

Steel drum: 800-1000kgs;

Container bag: 1000kgs.

- Q:Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q:How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q:Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

- Q:Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q:Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q:Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

- Q:What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

- Q:How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found. The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q:What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Chrome Casting Balls for Mining

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords