High Chrome Cast Iron Ball Mill Grinding Balls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

High Chromium Ball Mill Grinding Balls

| Application | Material comminution In cement/Mining/Power Industry |

| Size Range | 10mm-150mm |

| Chromium Percentage | 10%-26% |

| Production Standard | JC-T533-2004 and GB/T17445-2009 |

| Process Method | Cast |

| Microstructurer | M+C |

| Ball Breakage Rate Per Chamber | ≤0.5 |

Product Name | Designation | (HRC) Surface Hardness | Impact Toughness (AK J/cm2) | Microstructure | Specification(mm) |

| High Chromium Alloy Cast Grinding Balls | Cast Cr 26 | ≥59 | ≥3 | Martensite+ Carbide | Ø10, Ø12.7 ,Ø15,Ø17, Ø20 ,Ø25, Ø 30,Ø 35, Ø40, Ø50, Ø 60,Ø 70, Ø80, Ø90,Ø100, Ø110, Ø120 |

| Cast Cr 20 | |||||

| Cast Cr 17 | |||||

| Cast Cr 15 | |||||

| Cast Cr 12 | |||||

| Cast Cr 10 |

We can offer a variety of High Chromium grinding balls with different size and chromium percentage:

Size range from 10mm to 150mm

Chromium percentage from 10 to 26% ,or upon your request.

Grinding Balls Production Line

1.Sand Lined Iron Mold Casting Line,which is Applicable For Producing Grinding Balls With Diameter 40 To 150mm,Average Production Capability 2 Tonne Per Hour.

2.Flaskless Molding Casting Line:Be Suitable For Batch Production Of Casting Grinding Balls With Diameter 10 To 40mm,Casting Grinding Cylpeds With Dimension Range From 6*6mm To 40*45mm,And Even Small Castings.

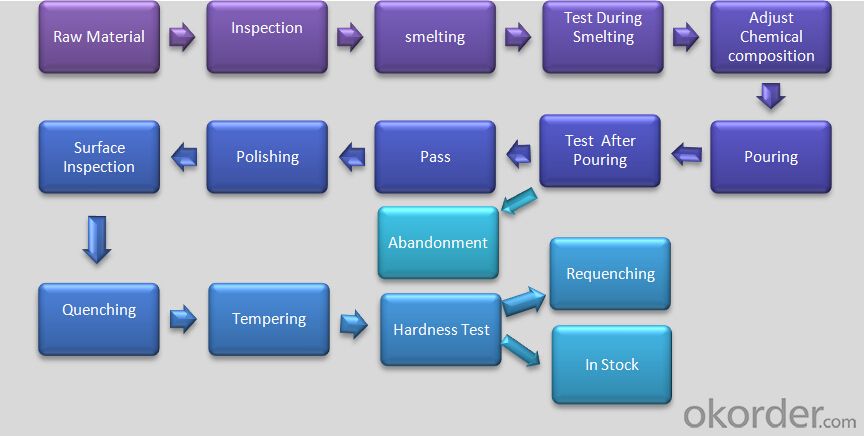

Production Process

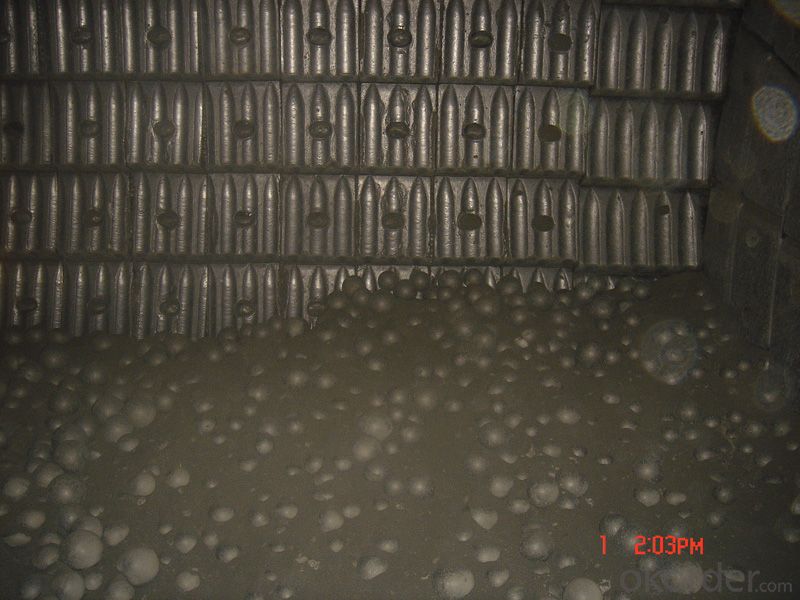

Detailed Images

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizingGenerally 0.06 mm or more

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

Send your message to us

High Chrome Cast Iron Ball Mill Grinding Balls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords