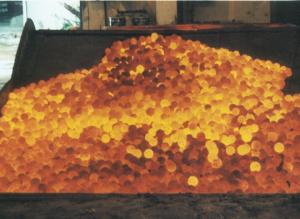

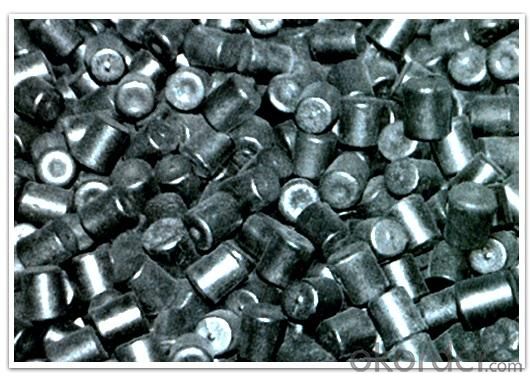

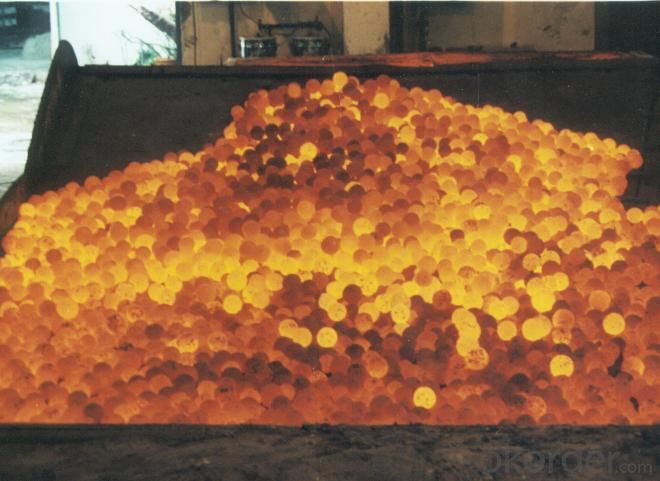

Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Best-quality High Chrome Casting Bars

CMAX products have excellent surface finish, high load carrying capacity, high intensity, high hardness, high wear ability, high temperature resistance, impact resistance, low damage percentage and so many other features. CMAX products can help corporations to promote production, reduce production cost, reduce labor intensity of the workers.

Specifications of Best-quality High Chrome Casting Bars

1)High hardness&low breakage

2)Good wear resistance

3)Reasonnable price

Application of Best-quality High Chrome Casting Bars

CMAX High Chrome Casting Bars are widely used in powder preparation and super finishing for the devices of cement, building materials, metallurgy, thermal power plant, ceramics, refractories and the other industries.

Our company has success in the products due to their cost-effectiveness, excellent strength and resistant properties. We also have experience in casting bars application and would like to assist you in product selection, system design, and installation techniques.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing? In the casting industry is not called proofing, proofing is generally used in the printing industry, that is, according to the customer's drawings or samples, to do a first piece, to provide customers with the inspection process to meet their requirements;In the foundry industry, providing prototypes is sometimes difficult:1, customers if the provision of mold, it would be best, at this time, sample costs are very low, and almost the same as your regular products;2, the customer does not provide the mold, but in business relationships, your factory and not very sure must take this one, it requires your leadership decision-making, is free or low cost, or by a strict process offer (of course sample);3, not all of the casting process to provide samples are difficult, like lost foam can directly make a white NC prototype, and then assembled pouring, this is her unique advantages, first cost less than the opening process and so on;If you don't understand, you can continue to question me

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

1. Manufacturer Overview

| Location | Anhui, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 million |

| Main Markets | Mid East; Eastern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 50% |

| No.of Employees in Trade Department | 31-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords