High Chrome Alloyed Casting & Forging Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

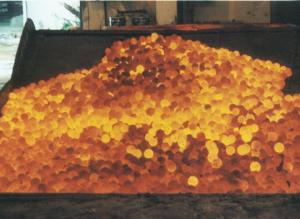

Specifications of Precision High Chrome Casting Balls

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Chrome Steel Ball

We are a professional manufacturer which produce media ball.Our steel ball exported to

Chemcial Elements of Chrome Steel Ball

Name | C | Mn | Si | Cr | S | P |

50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

60MN | 0.57-.0.65 | 0.7-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

Specification and Hardness of Chrome Steel Ball

Name | Impact Test AK.J/cm2 | Endurance Test Times (5m) | Dia 25mm-60mm | Dia 70mm-100mm | ||

Surface | Core | Surface | Core | |||

50MN | ≥12 | ≥10000 | ≥56 | ≥50 | ≥55 | ≥50 |

60MN | ≥13 | ≥12000 | ≥58 | ≥52 | ≥58 | ≥50 |

65MN | ≥15 | ≥12000 | ≥62 | ≥54 | ≥58 | ≥52 |

B2 | ≥15 | ≥12000 | ≥62 | ≥55 | ≥58 | ≥52 |

Weigh of Chrome Steel Ball

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT |

20mm/0.75'' | +1,-0.5 | 0.033 | 30303 |

25mm/1'' | +1,-0.5 | 0.064 | 15625 |

30mm/1.25'' | +2.0,-1.0 | 0.11 | 9090 |

40mm/1.5'' | +2.0,-1.0 | 0.261 | 3831 |

50mm/2'' | +2.0,-1.0 | 0.510 | 1961 |

60mm/2.5'' | +2.0,-1.0 | 0.883 | 1132 |

70mm/2.75'' | +3.0,-1.5 | 1.402 | 713 |

80mm/3.25'' | +3.0,-1.5 | 2.092 | 478 |

90mm/3.5'' | +3.0,-1.5 | 2.98 | 335 |

100mm/4'' | +3.0,-1.5 | 4.087 | 244 |

110mm/4.5'' | +3.0,-1.5 | 5.44 | 183 |

120mm/4.75 | +3.0,-1.5 | 7.062 | 141 |

Applied fields of Chrome Steel Ball

a).Mines

b).Cement plant

c).Chemical Industries

Chrome Steel Ball Packing

Steel drum: 800-1000kgs;

Container bag: 1000kgs.

- Q:Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q:What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q:How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q:How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q:How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q:What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q:What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q:Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q:The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q:Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

1. Manufacturer Overview |

|

|---|---|

| Location | Anhui, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 45 Million |

| Main Markets | Taiwan; Germany; Italy; Turkey; France; England; Japan; Thailand; Vietnam; Idonesia; Egypt; Ukraine; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20%-30% |

| No.of Employees in Trade Department | 3 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Fifty thousand tons per year |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Chrome Alloyed Casting & Forging Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products