FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

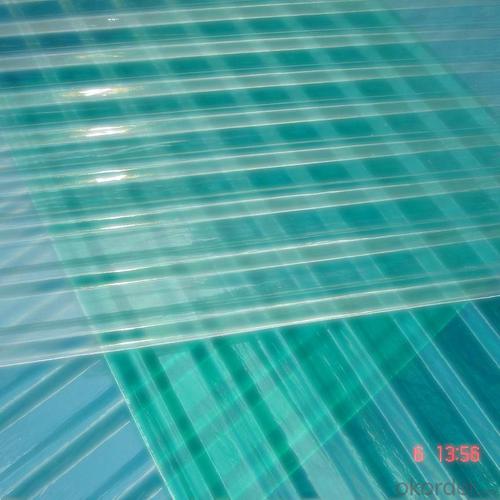

PICTURES

- Q: Are FRP roofing panels resistant to oil spills?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to oil spills. The material used in FRP roofing panels is non-porous, which means that oil spills will not penetrate the surface. This makes it easier to clean up and prevents the oil from seeping into the panels and causing damage. Additionally, FRP panels are known for their durability and resistance to various chemicals, including oils. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the FRP roofing panel. It is always recommended to check the manufacturer's specifications and guidelines for the specific panel you are using to ensure it is suitable for oil spill resistance.

- Q: Are FRP roofing panels resistant to UV degradation?

- Indeed, FRP roofing panels possess resistance against UV degradation. The fiberglass material utilized in FRP panels inherently exhibits UV resistance, rendering it an optimal selection for outdoor purposes including roofing. The panels undergo manufacturing processes incorporating specialized additives that bestow supplementary safeguarding against the detrimental impact of UV rays. These additives proficiently obstruct the UV radiation, thereby averting the panels from undergoing degradation or discoloration as time progresses. Consequently, this UV resistance guarantees that FRP roofing panels sustain their robustness, structural integrity, and visual allure, even when subjected to extended periods of direct sunlight exposure.

- Q: Are FRP roofing panels suitable for sports facilities?

- Sports facilities can benefit from the use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess various advantages that make them an excellent option for such venues. To begin with, FRP roofing panels are both lightweight and strong, making them perfect for the expansive roofs typically found in sports facilities. Their lightness also reduces the overall burden on the building structure. Additionally, FRP roofing panels are highly durable and resistant to weathering, UV radiation, and corrosion. This makes them well-suited for outdoor sports facilities that are constantly exposed to different weather conditions. Furthermore, FRP panels have a long lifespan, resulting in minimal maintenance and replacement costs over time. Moreover, these panels offer exceptional light transmission, enabling natural light to illuminate the sports facility. This creates a bright and well-lit environment for athletes and spectators, ultimately enhancing the overall experience. Furthermore, FRP roofing panels come in a variety of colors and finishes, allowing for customization to match the aesthetic requirements of the sports facility. They are also easy to install and comparatively cost-effective compared to other roofing materials. In conclusion, FRP roofing panels are an appropriate choice for sports facilities due to their lightweight nature, durability, resistance to weather, ability to transmit light, customization options, and cost-effectiveness.

- Q: Are FRP roofing panels resistant to efflorescence or salts?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to efflorescence and salts. Efflorescence is the white powdery substance that forms on the surface of materials when water evaporates and leaves behind salt deposits. FRP panels are made of a solid, non-porous material that does not absorb water, so they are less prone to efflorescence compared to other materials like concrete or masonry. Additionally, FRP panels are typically resistant to salts. Salts can cause corrosion and degradation of materials over time, but FRP is known for its exceptional resistance to chemicals and environmental elements. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the FRP roofing panel. To ensure the highest level of resistance to efflorescence and salts, it is recommended to choose FRP panels that have been specifically designed and manufactured for outdoor and high-exposure applications. It is also advisable to consult with the manufacturer or supplier to confirm the panel's resistance to efflorescence and salts in your specific environment or project conditions.

- Q: Can FRP roofing panels be used in agricultural storage buildings?

- Yes, FRP roofing panels can be used in agricultural storage buildings. FRP (Fiberglass Reinforced Plastic) roofing panels are durable, lightweight, and resistant to various environmental conditions such as moisture, UV rays, and chemicals. These qualities make them suitable for agricultural storage buildings where protection and longevity are important factors. Additionally, FRP panels provide excellent insulation and can help maintain a consistent temperature inside the building, which is beneficial for storing agricultural products.

- Q: Can FRP roofing panels be used for both indoor and outdoor applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both indoor and outdoor applications. FRP roofing panels are versatile and durable, making them suitable for various environments. They are commonly used in industrial buildings, commercial establishments, residential structures, and agricultural facilities. Indoors, FRP roofing panels are often used in areas that require natural light but cannot accommodate windows, such as warehouses, manufacturing facilities, and storage rooms. They provide excellent light transmission, reducing the need for artificial lighting and lowering energy costs. Additionally, FRP panels are resistant to moisture, chemicals, and UV rays, making them ideal for applications in areas with high humidity or exposure to harsh substances. Outdoors, FRP roofing panels are commonly used in patio covers, pergolas, and other outdoor structures to provide shade and protection from the elements. They are lightweight yet strong, making installation easier and ensuring long-lasting performance. FRP panels are also resistant to weathering, so they can withstand exposure to rain, snow, sunlight, and extreme temperatures without deteriorating or losing their structural integrity. Overall, FRP roofing panels are a versatile and cost-effective solution for both indoor and outdoor applications. They offer a range of benefits, including durability, light transmission, resistance to moisture and chemicals, and ease of installation, making them suitable for a wide range of projects.

- Q: Can FRP roofing panels be used in earthquake-prone areas?

- Yes, FRP roofing panels can be used in earthquake-prone areas. FRP (Fiber Reinforced Polymer) roofing panels are lightweight and have a high strength-to-weight ratio, making them a suitable choice for areas prone to earthquakes. They are flexible and can withstand seismic movements without cracking or shattering. Additionally, FRP panels have excellent resistance to corrosion and weathering, making them a durable option for earthquake-prone regions.

- Q: Are FRP roofing panels suitable for theme parks?

- Yes, FRP roofing panels are suitable for theme parks. They are lightweight, durable, and provide excellent protection against UV rays, extreme weather conditions, and corrosion. Additionally, FRP panels can be customized to match the theme park's aesthetic, making them a versatile and attractive roofing option.

- Q: Can FRP roofing panels be used for covered walkways in industrial parks or factories?

- Certainly, covered walkways in industrial parks or factories can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are favored for their ability to withstand harsh weather conditions, durability, and strength. Despite being lightweight, they possess exceptional impact resistance, making them ideal for high-traffic areas like walkways within industrial environments. Furthermore, FRP panels do not corrode and exhibit outstanding UV resistance, guaranteeing long-lasting performance and minimal upkeep. All in all, FRP roofing panels offer a dependable and cost-efficient remedy for covered walkways in industrial parks or factories.

- Q: Can FRP roofing panels be used for car washes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for car washes. FRP panels are commonly used in industrial and commercial settings, including car washes, due to their durability, strength, and resistance to various chemicals and weather conditions. These panels are known for their ability to withstand moisture, UV rays, and extreme temperatures, making them ideal for car wash environments where they are constantly exposed to water, cleaning solutions, and sunlight. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, which further enhances their suitability for car wash applications.

Send your message to us

FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords