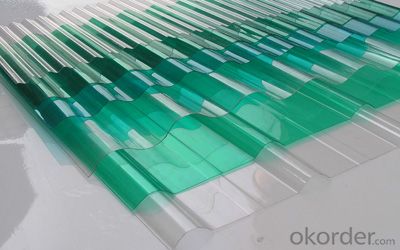

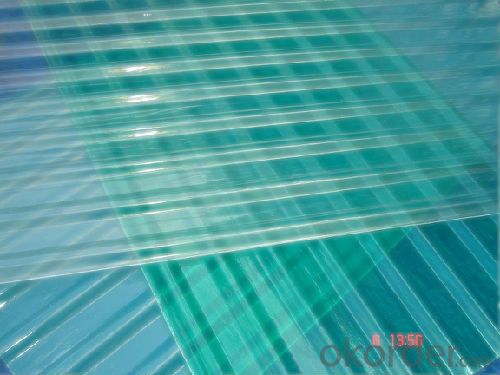

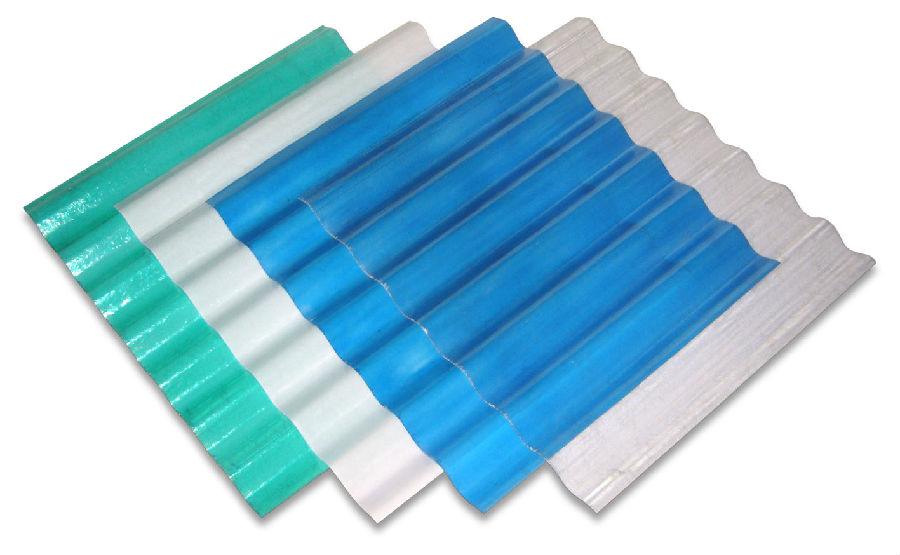

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Fibreglass sheet,FRP panels,fibreglass panel,corrugated sheet can be used in many kinds of fileds such as building etc.It includes transparent ,lightblue ,red and other colors.

2.Characteristics

1)High light transparency

2)Light weight and high strength

3)Corrosion and impact resistance

4)Anti-UV, anti-static, insulation

5)Accurate cross-section size

6)The length of the random cutting and more

7)Widely used in industrial plants, large-scale treasury markets, greenhouse, aquaculture and tourism

8)Used as roof, wall panel and more

9)Supports good lighting effect

3.Technical Data Sheet

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 to +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

Warranty:15 years

Item | Data | Reference | Item | Data | Reference |

Tensile modulus(Gpa) | 6.92 | GB | catalyst cold temperature | -52 | GB |

tensile strength(Gpa) | 103 | GB | heat distortion temperature | 172 | GB |

flexural modulus(Gpa) | 6.00 | GB | glass fiber content | above30% | GB |

flexural strength(Gpa) | 171 | GB | water absorption% | 0.18 | GB |

shear strength(Gpa) | 89.9 | GB | specific gravity | 1.48g/cm² | GB |

Barcol hardness | 47 | GB | Coefficient of thermal expansion | 1.5-2.2*10-5 | GB |

4.FAQ

a.Delivery Time: The products will be ready in 10-15 days after getting the advance payment or LC.

b.Payment Term:30% T/T in advance,70% againest B/L copy or LC.

- Q: Are FRP roofing panels suitable for educational or institutional buildings?

- Educational or institutional buildings can benefit from the use of FRP roofing panels. FRP, which stands for fiber reinforced plastic, is a durable and lightweight material. These panels possess several advantages that make them well-suited for such structures. To begin with, FRP roofing panels demonstrate high resistance to corrosion, UV rays, and other weathering elements. This quality renders them ideal for educational and institutional buildings, which are often exposed to harsh weather conditions. By resisting corrosion, they can endure the test of time and provide long-lasting protection for the building. In addition, FRP roofing panels are easy to install and maintain. Their lightweight nature simplifies the installation process, reducing the time and effort required. Furthermore, their smooth surface allows for easy cleaning and maintenance. This is especially advantageous for educational or institutional buildings that must maintain a clean and hygienic environment. Another benefit of FRP roofing panels is their impressive strength-to-weight ratio. Despite their lightweight nature, these panels possess remarkable strength, ensuring excellent structural integrity for the building. This strength guarantees that the roofing panels can withstand heavy loads, such as snow or equipment installations, without compromising the safety of the building occupants. Moreover, FRP roofing panels offer design flexibility. They are available in various colors, finishes, and profiles, allowing for customization to match the architectural aesthetics of the educational or institutional building. This ensures that the roofing panels not only provide functional benefits but also enhance the overall appearance of the structure. In conclusion, FRP roofing panels are indeed suitable for educational or institutional buildings. Their resistance to corrosion and weathering, ease of installation and maintenance, high strength-to-weight ratio, and design flexibility make them a practical and reliable roofing solution for such buildings.

- Q: What is the installation process for FRP roofing panels?

- Typically, the installation process for FRP (Fiberglass Reinforced Plastic) roofing panels involves the following steps: To begin, the roof surface must be thoroughly cleaned and prepared for installation. This may include the removal of existing roofing materials, cleaning the surface, and ensuring it is smooth and clear of any debris or protrusions. Accurate measurements of the roof are then taken to determine the required size and number of FRP panels. These panels are subsequently cut to the appropriate dimensions using a saw or similar cutting tool. It is important to wear safety glasses and gloves when cutting FRP panels for protection. Next, the first panel is positioned at the edge of the roof and securely fastened using suitable fasteners such as screws or nails. The subsequent panels are then overlapped with the previous one and also fastened down in a similar manner. This overlapping technique ensures a watertight seal and prevents any water infiltration. Once all the panels are successfully installed, any gaps or joints between them are sealed using a suitable sealant. This further enhances the waterproofing properties of the roof. Additionally, trim pieces may be used to cover exposed edges or corners, providing a more polished appearance. To ensure a proper and durable installation, it is crucial to carefully follow the manufacturer's instructions and guidelines. If you are unfamiliar with the installation process or have any doubts, it is recommended to consult with a professional or experienced contractor.

- Q: Are FRP roofing panels suitable for water treatment plants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for water treatment plants. FRP panels are known for their excellent resistance to water, corrosion, and chemicals, making them an ideal choice for environments that require protection against water and chemical exposure. Additionally, FRP roofing panels are lightweight, durable, and have a long lifespan, making them cost-effective and low-maintenance solutions for water treatment plants. They also offer excellent UV resistance, ensuring that they can withstand prolonged exposure to sunlight without deteriorating. Overall, FRP roofing panels are a suitable and reliable option for water treatment plants, providing the necessary durability and protection required in such environments.

- Q: Do FRP roofing panels have a warranty against fading or discoloration?

- Yes, FRP roofing panels typically come with a warranty against fading or discoloration. The specific terms and duration of the warranty may vary depending on the manufacturer, so it is best to consult the product documentation or contact the manufacturer directly for detailed information.

- Q: Are FRP roofing panels suitable for museums or art galleries?

- Depending on various factors, FRP roofing panels may be suitable for use in museums or art galleries. They have several advantages that make them a popular roofing choice in different settings. To begin with, the lightweight nature of FRP panels makes them easy to install and reduces the burden on the building structure. This is particularly advantageous for museums or art galleries with delicate artworks, as it minimizes the risk of damage during installation. Moreover, FRP panels are highly durable and resistant to weathering, UV radiation, and corrosion. This makes them ideal for safeguarding valuable collections in museums or art galleries from potential harm caused by external elements. Additionally, FRP panels possess excellent light transmission properties, allowing natural light to enter the building and creating a bright and inviting atmosphere for visitors. This is especially crucial in museums or art galleries where proper lighting is essential for displaying artwork or exhibits. Furthermore, FRP panels can be customized to meet specific design requirements. They are available in various colors, finishes, and textures, providing flexibility in creating visually appealing roofing systems that complement the architectural style of the museum or art gallery. However, before determining the suitability of FRP roofing panels, it is vital to consider the specific needs and conditions of the museum or art gallery. Factors such as location, climate, and architectural design should be taken into account to ensure that the panels can provide adequate insulation, ventilation, and protection against potential hazards. In conclusion, FRP roofing panels can be a viable option for museums or art galleries. Their lightweight nature, durability, light transmission properties, and customization options make them suitable for protecting valuable collections while creating an aesthetically pleasing environment for visitors. However, it is crucial to assess the specific requirements of each facility to determine if FRP panels are the best choice.

- Q: Are FRP roofing panels resistant to yellowing over time?

- Yes, FRP roofing panels are resistant to yellowing over time.

- Q: Can FRP roofing panels be used for museums?

- Yes, FRP roofing panels can be used for museums. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, flexibility, and resistance to corrosion, making them suitable for protecting valuable artifacts and exhibits in museums. Additionally, FRP panels can provide natural lighting and UV protection, creating a conducive environment for showcasing artwork and preserving historical items.

- Q: Are FRP roofing panels prone to cracking or warping?

- The durability and resistance to cracking or warping are characteristics commonly associated with FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess remarkable strength and structural integrity due to their composition of fiberglass and plastic. In comparison to materials like wood or metal, FRP panels exhibit a relatively low coefficient of expansion. Consequently, they undergo minimal expansion and contraction when subjected to temperature fluctuations, thereby reducing the likelihood of cracking or warping. Furthermore, the fiberglass reinforcement incorporated into FRP panels enhances their strength and rigidity, rendering them less vulnerable to damage caused by impacts or heavy loads. This attribute makes them a favored option for industrial and commercial environments, where durability is of utmost importance. Nevertheless, it is crucial to acknowledge that the quality of FRP panels can vary based on the manufacturer and specific production process. Inferior panels or those not installed correctly may be more susceptible to cracking or warping. Hence, it is imperative to select a reputable manufacturer and ensure proper installation to optimize the longevity and performance of FRP roofing panels.

- Q: Can FRP roofing panels be used in earthquake-prone areas?

- FRP roofing panels are suitable for use in areas prone to earthquakes. These panels are recognized for their robustness, longevity, and ability to withstand various environmental factors, including seismic activity. They are specifically engineered to endure strong winds, heavy rainfall, and earthquakes. Utilizing FRP roofing panels in earthquake-prone areas presents numerous benefits. Firstly, these panels are lightweight, reducing the overall structural load on buildings. This aids in minimizing the impact of seismic forces on the foundation and structure of the building. Secondly, FRP panels possess high tensile strength, enabling them to withstand the stress and movement caused by earthquakes. Their flexibility allows them to absorb and distribute seismic energy, lowering the risk of damage or collapse. Additionally, FRP panels exhibit exceptional impact resistance, a critical characteristic in areas susceptible to earthquakes where debris and falling objects can cause substantial harm. Moreover, FRP panels are non-corrosive and possess a long lifespan, making them an ideal choice for earthquake-prone regions. They do not rust or deteriorate over time, ensuring durability and reliability during seismic events. It is essential to acknowledge that the installation and design of FRP roofing panels in earthquake-prone areas must comply with local building codes and regulations. Adequate structural support and appropriate anchoring methods are crucial to optimize the performance and safety of FRP roofing panels during seismic events. In conclusion, FRP roofing panels can effectively be utilized in earthquake-prone areas, offering a resilient and dependable roofing solution capable of withstanding the challenges presented by seismic activity.

- Q: Are FRP roofing panels resistant to warping or bending?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping or bending. Due to their composition of reinforced fibers and plastic resins, FRP roofing panels possess exceptional strength and rigidity, making them highly resistant to deformation caused by external forces. This resistance to warping or bending makes FRP panels a reliable and durable choice for roofing applications. Additionally, FRP panels have excellent dimensional stability, meaning they can maintain their shape and structural integrity even under extreme temperature fluctuations or prolonged exposure to the elements. Overall, FRP roofing panels are known for their robustness and ability to withstand various environmental conditions without warping or bending.

Send your message to us

High strength Transparent corrugated FRP/GRP panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords