FRP Roofing Panel S15 - High Quality FRP Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Roofing Panel S15

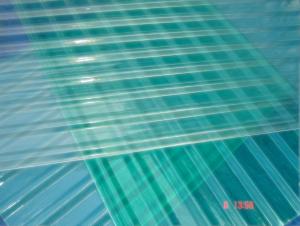

Thickness:2.0mm

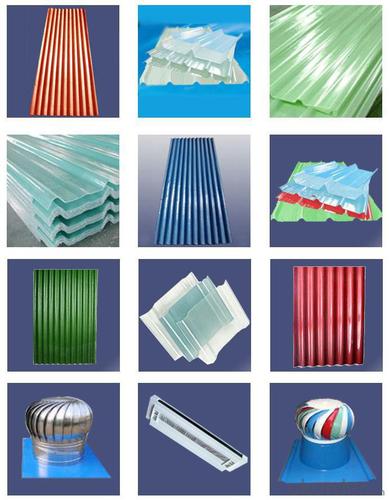

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.Ordinary Wave: 950-237,

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel S15:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery of FRP Roofing Panel S15:

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q: Are FRP roofing panels suitable for flat roofs?

- Yes, FRP roofing panels are suitable for flat roofs. They are a durable and lightweight option that provide excellent protection against weather elements, making them ideal for flat roof applications. Additionally, FRP panels offer good insulation properties and are resistant to corrosion, making them a reliable choice for flat roof installations.

- Q: Are FRP roofing panels suitable for recreational areas?

- Recreational areas can be effectively equipped with FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are renowned for their durability and ability to withstand various weather conditions, making them an optimal choice for outdoor environments. Their capacity to resist UV rays prevents fading and damage caused by sunlight exposure. Moreover, FRP panels are lightweight and simple to install, making them a cost-efficient option for recreational areas. In addition, FRP roofing panels provide excellent insulation, creating a comfortable and controlled atmosphere in recreational spaces. They can endure high temperatures, extreme cold, and are resistant to corrosion, making them suitable for areas with elevated moisture levels like swimming pool enclosures or outdoor play areas. Furthermore, FRP roofing panels come in a wide range of colors and designs, allowing for customization and enhancing the aesthetic appeal of recreational areas. They are easy to clean and maintain, guaranteeing a visually pleasing and long-lasting roof for years to come. Nevertheless, it is important to note that the suitability of FRP roofing panels for recreational areas may vary depending on the specific requirements and intended use of the space. It is advisable to consult a professional roofing contractor or engineer to determine the most suitable roofing material for your particular recreational area.

- Q: Can FRP roofing panels be installed on curved roofs?

- Yes, FRP roofing panels can be installed on curved roofs. They are flexible and can be bent or molded to fit the shape of curved roofs without compromising their structural integrity.

- Q: Are FRP roofing panels resistant to cracking or splitting from seismic activity?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their high resistance to cracking or splitting during seismic activity. The flexibility and strength of the fiberglass material used in FRP panels allow them to absorb and distribute the stress caused by seismic movements, reducing the risk of damage. Therefore, FRP roofing panels are considered a durable and reliable choice in areas prone to seismic activity.

- Q: Can FRP roofing panels be used in areas with heavy snowfall?

- FRP roofing panels are suitable for areas with heavy snowfall due to their durability and strength. However, certain factors need to be considered. The pitch or slope of the roof is important. A steeper pitch allows snow to slide off easily, reducing the risk of accumulation and potential damage to the panels. Proper installation techniques should also be followed to ensure the panels are securely fastened and sealed, preventing snow or water infiltration. Regular removal of accumulated snow is advisable to prevent excessive weight on the panels. Safe and appropriate snow removal techniques, such as using a roof rake or hiring professionals, should be employed. Choosing FRP roofing panels specifically designed and rated for heavy snow loads is essential. These panels are reinforced and have higher load-bearing capacities, ensuring they can withstand the weight and stress caused by heavy snow accumulation. Overall, by properly installing, maintaining, and selecting appropriate panels, FRP roofing panels can be effectively used in areas with heavy snowfall.

- Q: Can FRP roofing panels be cut or trimmed to fit different roof shapes?

- FRP roofing panels have the ability to be cut or trimmed in order to adapt to different roof shapes. Typically composed of a lightweight and flexible material, FRP panels can be easily shaped and cut. Common tools such as a circular saw, jigsaw, or utility knife can be used for this purpose. It is crucial to accurately measure and mark the desired dimensions before cutting to ensure a precise fit. Moreover, wearing appropriate safety gear like goggles and gloves is highly recommended when working with FRP panels, in order to protect against potential hazards. In conclusion, with the right tools and precautions, FRP roofing panels can be effortlessly cut or trimmed to suit a variety of roof shapes.

- Q: Do FRP roofing panels require a specific type of flashing?

- FRP roofing panels necessitate a particular kind of flashing to ensure their proper installation. Flashing is vital in any roofing system as it not only prevents water leaks but also diverts water away from vulnerable areas. In the case of FRP roofing panels, it is essential to use flashing that is compatible with the material and specifically designed for FRP roofs. When choosing flashing for FRP roofing panels, the material is a primary consideration. FRP panels are constructed from fiberglass reinforced plastic, a lightweight and durable substance. Consequently, the flashing used should also be lightweight and flexible to guarantee a snug fit and an effective seal. Another crucial factor to bear in mind is the design of the flashing. FRP roofing panels possess a unique profile, necessitating flashing that can accommodate their distinct shape and size. This may involve customized flashing or specialized flashing designed explicitly for FRP roofs. The flashing must be capable of covering the panels' edges and creating a watertight seal to prevent water from infiltrating beneath the panels and causing damage. To determine the specific type of flashing required for FRP roofing panels, it is always advisable to consult a professional roofing contractor or manufacturer. They possess the knowledge and expertise necessary to recommend the most suitable flashing option based on the specific characteristics of the FRP panels and the environmental conditions in which they will be installed. By utilizing the correct flashing, you can ensure the longevity and performance of your FRP roofing system.

- Q: Can FRP roofing panels be used in data centers or server rooms?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in data centers or server rooms. FRP panels are known for their durability, thermal insulation properties, and resistance to moisture, chemicals, and corrosion. These characteristics make them suitable for use in environments where temperature and humidity control are crucial, such as data centers and server rooms. Additionally, FRP roofing panels are lightweight, easy to install, and offer good light transmission, which can contribute to energy efficiency and cost savings in these facilities. Overall, FRP roofing panels can effectively meet the requirements of data centers and server rooms, providing a reliable and durable roofing solution.

- Q: Can FRP roofing panels be used for hotels?

- Yes, FRP roofing panels can be used for hotels. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and have excellent resistance to weathering, making them suitable for various applications including hotels. They offer benefits such as energy efficiency, easy installation, and low maintenance requirements, making them a viable option for hotel roofing.

- Q: Are FRP roofing panels resistant to pests and insects?

- FRP roofing panels, usually, possess resistance against pests and insects. Comprised of a composite material, FRP panels do not entice pests and insects like termites, ants, and beetles. Furthermore, the manufacturing process of FRP panels ensures the absence of any openings or crevices that could serve as entry points or nesting spots for pests and insects. Hence, FRP roofing panels prove to be an exceptional option for averting infestations and the subsequent harm caused by pests and insects.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel S15 - High Quality FRP Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords