FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

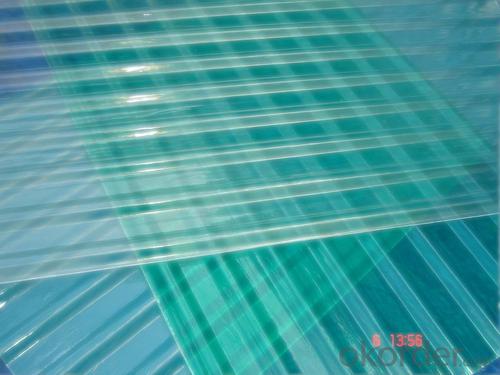

Specification of FRP Roofing Panel

Thickness:1.2mm

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.

Ordinary Wave: 760-380

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q: Can FRP roofing panels be used for universities?

- Yes, FRP roofing panels can definitely be used for universities. FRP (Fiberglass Reinforced Plastic) roofing panels offer a range of benefits that make them suitable for university buildings. Firstly, FRP panels are lightweight yet strong, making them easy to install and providing durability to withstand harsh weather conditions. This is particularly important for university buildings that need to endure heavy rain, snow, and wind. Another advantage of FRP roofing panels is their resistance to corrosion and UV rays. This ensures a longer lifespan and reduces maintenance costs for the university. Additionally, FRP panels are highly customizable, available in a variety of colors, styles, and finishes. This allows universities to choose panels that match their architectural design and enhance the overall aesthetics of the campus. Moreover, FRP roofing panels are energy-efficient, as they can be designed to allow natural light transmission, reducing the need for artificial lighting during the day. This not only saves energy but also creates a comfortable and well-lit environment for students and staff. In terms of sustainability, FRP roofing panels are made from recycled materials and are fully recyclable at the end of their life span. This aligns with the growing focus on environmental responsibility in universities and contributes to their green initiatives. Overall, FRP roofing panels are a suitable choice for universities due to their strength, durability, resistance to corrosion and UV rays, customizable designs, energy efficiency, and sustainability.

- Q: Are FRP roofing panels suitable for DIY installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be suitable for DIY installation depending on the level of experience and skill of the individual. FRP roofing panels are lightweight, durable, and easy to handle, making them a popular choice for do-it-yourself projects. However, it is important to note that proper installation techniques and safety precautions should be followed to ensure a successful installation. This may include wearing appropriate protective gear, using the correct tools, and following the manufacturer's instructions. Additionally, it is recommended to consult with a professional or seek advice from reputable sources to ensure that the installation is done correctly and meets local building codes.

- Q: Are FRP roofing panels suitable for agricultural or farm buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for agricultural or farm buildings. FRP roofing panels are known for their durability, strength, and resistance to various weather conditions, making them ideal for use in farm buildings. These panels are lightweight, which makes installation easier and cost-effective. Additionally, FRP panels provide excellent UV resistance, ensuring that they will not degrade or discolor over time when exposed to sunlight. The non-corrosive nature of FRP roofing panels is also a significant advantage, as it makes them highly resistant to chemicals, moisture, and other substances commonly found in agricultural environments. Furthermore, FRP panels offer good insulation properties, helping to regulate temperature and reducing energy costs. Overall, FRP roofing panels are a reliable and practical option for agricultural or farm buildings due to their strength, durability, weather resistance, and other beneficial characteristics.

- Q: Are FRP roofing panels suitable for oil refineries or petrochemical plants?

- Indeed, FRP roofing panels are suitable for oil refineries and petrochemical plants. They offer a range of advantages that make them ideal for industrial environments like these. To begin with, FRP panels are highly resistant to corrosion, which is crucial in facilities where exposure to various chemicals and corrosive substances is common. Unlike traditional roofing materials such as metal or concrete, FRP panels do not rust or deteriorate when exposed to chemicals or harsh weather conditions. Moreover, FRP roofing panels are lightweight yet extremely durable. This makes them easier to install and reduces the structural load on the building, while still offering excellent strength and impact resistance. Additionally, their flexibility allows for easy customization and fitting to various roof shapes and sizes. Furthermore, FRP panels provide excellent insulation properties, helping to maintain a stable temperature within the facility. This insulation helps reduce energy consumption and ensures a comfortable working environment for employees. Additionally, FRP roofing panels are UV resistant, minimizing the effects of prolonged exposure to sunlight and preventing color fading or degradation. This is particularly important in outdoor areas of refineries and petrochemical plants where direct sunlight can be intense. Lastly, FRP panels are cost-effective in the long run. Due to their durability and resistance to corrosion, they require minimal maintenance and have a longer lifespan compared to other roofing materials. This reduces repair and replacement costs over time. In conclusion, FRP roofing panels are well-suited for use in oil refineries and petrochemical plants due to their corrosion resistance, durability, lightweight nature, insulation properties, UV resistance, and cost-effectiveness. They provide a reliable and long-lasting roofing solution that can withstand the harsh conditions and demands of these industrial environments.

- Q: Can FRP roofing panels be used in high-temperature environments?

- Certainly! FRP roofing panels are capable of being utilized in environments with high temperatures. Their design is specifically engineered to endure a wide range of temperatures, making them commonly employed in industries where elevated temperatures are prevalent, such as chemical processing plants, power plants, and industrial manufacturing facilities. A significant advantage of FRP roofing panels lies in their remarkable resistance to heat. They can endure temperatures of up to 200 degrees Celsius (392 degrees Fahrenheit) without experiencing warping, melting, or deformation. This characteristic renders them ideal for use in environments where high temperatures pose a concern. Moreover, FRP panels possess low thermal conductivity, meaning they do not easily transfer heat. This quality aids in maintaining a stable temperature within the structure, providing insulation against extreme heat. It also contributes to energy efficiency by reducing the necessity for supplementary cooling systems. In addition to their heat resistance, FRP roofing panels offer a multitude of other advantages. They are lightweight, durable, and boast a lengthy lifespan, making them a cost-effective choice for high-temperature environments. Additionally, they possess corrosion-resistant and UV-stable properties, ensuring their ability to withstand harsh weather conditions and prolonged exposure to sunlight. Nevertheless, it is crucial to note that the specific temperature limitations for FRP panels may vary depending on the manufacturer and the specific product. Consequently, consulting the manufacturer's guidelines and specifications is imperative to ensure that the FRP roofing panels are suitable for the intended high-temperature environment.

- Q: Can FRP roofing panels be used for carports?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used for carports. FRP panels are known for their durability, strength, and resistance to weather elements, making them a suitable choice for carport roofs. They can effectively protect cars from rain, snow, and harmful UV rays. Additionally, FRP panels are lightweight and easy to install, making them an ideal option for carport construction. Overall, FRP roofing panels offer a cost-effective and reliable solution for carport roofs.

- Q: Can FRP roofing panels be used for sound barriers?

- Indeed, FRP roofing panels possess the capability to serve as sound barriers. Demonstrating exceptional acoustic attributes, these panels prove highly effective in diminishing noise transmission. Tailored to absorb and impede sound waves, they successfully hinder the passage of such waves through the barrier. Consequently, FRP roofing panels emerge as an optimal selection for sound barriers across diverse spheres, encompassing highways, railways, industrial zones, and construction sites. Furthermore, their lightweight nature, durability, and straightforward installation render FRP panels an immensely practical solution for soundproofing requirements.

- Q: Are FRP roofing panels resistant to wind uplift?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to wind uplift. The strong and durable nature of FRP panels allows them to withstand strong winds and prevent them from being lifted off the roof. These panels are designed to be securely fastened to the roof structure, ensuring stability and minimizing the risk of wind damage. Additionally, FRP panels are lightweight, reducing the overall stress on the roof and further enhancing their wind resistance. However, it is important to note that the specific wind uplift resistance of FRP roofing panels may vary depending on factors such as panel thickness, installation method, and the severity of wind conditions. Therefore, it is always recommended to consult with a professional or follow the manufacturer's guidelines to ensure proper installation and optimal wind resistance.

- Q: Can FRP roofing panels be used in prisons or correctional facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in prisons or correctional facilities. FRP panels are highly durable, resistant to damage, and have low maintenance requirements, making them suitable for such facilities. They are also lightweight, non-corrosive, and resistant to water, chemicals, and fire, which are important considerations in secure environments like prisons. Additionally, FRP panels can be customized to meet specific security and safety requirements, making them a viable option for roofing in correctional facilities.

- Q: Are FRP roofing panels resistant to bird pecking?

- FRP roofing panels are known for their ability to withstand bird pecking. Unlike asphalt shingles or wooden panels, FRP panels are highly durable and strong, minimizing the risk of damage caused by bird pecking. Additionally, the smooth surface of FRP panels acts as a deterrent for birds, discouraging them from perching and pecking. However, it is important to be aware that while FRP panels are resistant to bird pecking, they may still experience minor scratches or damage if birds repeatedly target a specific area. Regular inspection and maintenance are crucial to ensure the longevity and effectiveness of FRP roofing panels.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords