FRP Roofing Panel - Transparent Skylight GRP/FRP Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Roofing Sheets usually use a protecting facility in construction site,steel structured workshop and

warehouse,canopy,packing sheds,corridors,studio light awning and greenhouse etc as the excellent light

transmittance.FRP plane skylight is the more strengthened, safety, and more econimal greenhouse panel with the properties of waterproof,good light transmittance,heat insulation,strong impact resistant, withstand extreme temperature.

FEATURES

1.Light transmission

The light transmission of FRP roof Sheet is between 60-85%. Light through FRP corrugated Sheet

scatters and is mild. It will not form a light band so as to make the indoor brighter.

2.Weather resistance

The anti-aging film covering on the surface of FRP corrugated sheet improves its property of weather

resistance. The anti- ultraviolet adsorbing agent mixing in the raw materials absorbs 99.9% of ultraviolet

ray of the visible light transmitted through the FRP sheets.

3.Corrosion resistance

The products resist various acids, alkalis and peroxides, especially suitable for application in the coastal

areas and corrosive places.Temperature performance and insulation FRP roof Sheet is a kind of hot solid

high polymer materials. It is designed for normal use in temperatures - 40℃~120℃ .The coefficient of heat

conduction of FRP roof Sheet is only 1/4 of the glass.

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

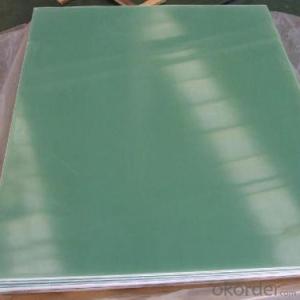

PICTURES

- Q: Do FRP roofing panels require any special tools for installation?

- Installation of FRP roofing panels typically necessitates the use of specific tools. These tools may encompass a power drill equipped with proper bits, a circular saw or a jigsaw to tailor panels to the desired dimensions, a tape measure, a level, a ladder or scaffolding for roof access, a caulking gun for applying sealant, as well as roofing nails or screws to fasten the panels to the roof structure. Furthermore, during the installation process, it is essential to wear a safety harness and appropriate personal protective gear such as gloves and safety glasses. To ascertain the specific tools required for the installation of FRP roofing panels, it is crucial to refer to the manufacturer's instructions and guidelines, as the requirements might differ based on the panel design and installation method.

- Q: Can FRP roofing panels be used in wastewater treatment plants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in wastewater treatment plants. FRP panels are known for their excellent corrosion resistance, durability, and low maintenance requirements, making them a suitable choice for such harsh environments. Additionally, FRP panels are lightweight, easy to install, and can be customized to fit specific project requirements. They also provide superior resistance to chemicals, UV rays, and weathering, ensuring long-term performance and cost-effectiveness. Overall, FRP roofing panels are a reliable option for wastewater treatment plants due to their ability to withstand corrosive conditions while providing a strong and durable roofing solution.

- Q: Can FRP roofing panels be used for both residential and commercial skylights?

- FRP roofing panels are indeed applicable for skylights in both residential and commercial purposes. These panels possess remarkable traits such as being lightweight, durable, and having exceptional light transmission capabilities, which render them perfect for skylights in residential and commercial environments alike. They exhibit resistance towards UV rays, weathering, and impacts, thereby guaranteeing enduring performance and reduced upkeep. Furthermore, these FRP panels offer customization options regarding size, shape, and color in order to accommodate various design preferences and meet the precise specifications of any residential or commercial skylight undertaking.

- Q: Are FRP roofing panels resistant to graffiti or paint overspray?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to graffiti or paint overspray. The smooth surface of FRP panels makes it easier to remove graffiti or paint, and they can be cleaned using mild detergents without causing damage. However, it's important to note that certain types of graffiti or aggressive cleaning methods may require additional measures for complete removal.

- Q: Can FRP roofing panels be used for military or defense installations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for military or defense installations. FRP panels are known for their strength, durability, and resistance to corrosion, making them suitable for various applications in military and defense settings. They are often used for shelters, hangars, ammunition storage, command centers, and other structures where reliability and protection are essential. Additionally, FRP panels offer benefits such as lightweight construction, ease of installation, and low maintenance requirements, making them a practical choice for military and defense installations.

- Q: Can FRP roofing panels be used for industrial facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for industrial facilities. FRP panels are known for their durability, strength, and resistance to various environmental conditions, making them suitable for industrial applications. They are lightweight, yet sturdy, which allows for easy installation and reduces the need for additional structural support. FRP roofing panels also offer excellent resistance to corrosion, chemicals, and UV radiation, making them ideal for industrial environments where exposure to harsh substances or intense sunlight is common. They have a low thermal conductivity, providing good insulation properties and helping to maintain a comfortable temperature inside the facility. Furthermore, FRP panels are available in various profiles, colors, and thicknesses, allowing for customization and integration with the overall design of the industrial facility. They are easy to clean and maintain, which is essential in industrial settings where cleanliness and hygiene are important. Overall, FRP roofing panels are a reliable and cost-effective solution for industrial facilities, providing durability, resistance, insulation, and aesthetic flexibility.

- Q: Are FRP roofing panels suitable for green buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for green buildings for several reasons. Firstly, FRP panels are highly durable and have a long lifespan, which means they require less maintenance and replacement over time. This reduces the overall environmental impact and waste associated with roofing materials. Secondly, FRP panels are lightweight, which reduces the load on the building's structure and can contribute to energy savings during construction and transportation. The reduced weight also allows for easier installation and handling, which can further reduce energy consumption. Additionally, FRP roofing panels have excellent thermal insulation properties, which can contribute to energy efficiency in green buildings. They can help regulate indoor temperature, reducing the need for excessive heating or cooling, and therefore decreasing energy consumption. Furthermore, FRP panels are resistant to corrosion, chemicals, and UV radiation, ensuring their long-lasting performance even in harsh weather conditions. This durability reduces the need for frequent repairs or replacements, which minimizes waste and resource consumption. Lastly, FRP panels are often made from recycled materials and can be recycled at the end of their lifespan, making them an environmentally friendly choice. By opting for FRP roofing panels in green buildings, not only are potential energy savings and environmental benefits achieved, but also the overall sustainability of the building is enhanced.

- Q: Are FRP roofing panels resistant to tree damage?

- Yes, FRP (Fiberglass-Reinforced Plastic) roofing panels are generally resistant to tree damage. FRP panels are known for their durability and strength, making them less vulnerable to impacts and potential damage from falling tree limbs or branches. The fiberglass reinforcement in these panels adds an extra layer of protection, making them more resistant to cracking or breaking upon impact. However, it's important to note that while FRP roofing panels are designed to be resistant to tree damage, they are not entirely immune to it. In extreme cases, such as a large tree falling directly onto the roof, some damage may occur. Overall, though, FRP roofing panels offer a high level of resistance to tree damage and are a reliable choice for protecting your roof from potential harm.

- Q: Can FRP roofing panels be used for green roofs?

- FRP roofing panels are indeed suitable for green roofs, as they are specifically designed to accommodate the growth of plants and vegetation. With their lightweight, durable, and highly resistant properties against water and weathering, FRP panels make an ideal foundation for green roof applications. Moreover, these panels can be customized to include specialized features such as drainage systems or built-in insulation, further augmenting their suitability for green roof installations. In summary, FRP roofing panels provide a dependable and enduring solution for constructing green roofs.

- Q: Do FRP roofing panels require any special ventilation or air circulation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require special ventilation or air circulation, although the extent of the ventilation requirements may vary depending on the specific application and the environment in which they are installed. FRP panels are designed to withstand a wide range of temperatures and weather conditions, but proper ventilation is crucial to ensure their longevity and prevent potential issues. The primary reason for providing ventilation is to prevent the buildup of heat and moisture underneath the roofing panels. Without adequate ventilation, heat can accumulate, which may lead to thermal expansion and potential damage to the panels. Additionally, moisture buildup can result in condensation, which could cause corrosion or the growth of mold and mildew. To ensure proper ventilation, it is recommended to install a ventilation system that allows air to circulate beneath the roofing panels. This can be achieved through the use of ridge vents, soffit vents, or other types of ventilation systems that provide both intake and exhaust airflow. The specific design and size of the ventilation system will depend on factors such as the size of the roof, the climate, and the local building codes and regulations. It is important to consult the manufacturer's guidelines and recommendations for the specific FRP roofing panels being used, as they may have specific requirements for proper ventilation. Additionally, it is advisable to work with a professional roofing contractor who can assess the specific needs of your project and ensure that proper ventilation is provided. In summary, FRP roofing panels do require special ventilation or air circulation to prevent heat buildup and moisture condensation. Providing adequate ventilation is essential for maintaining the integrity and longevity of the panels and ensuring a healthy environment underneath the roof.

Send your message to us

FRP Roofing Panel - Transparent Skylight GRP/FRP Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords