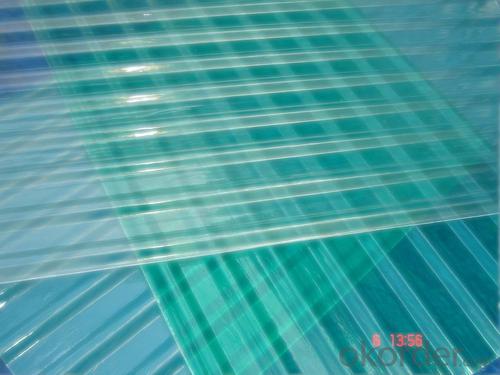

FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP plane skylightusually use a protecting facility in construction site,steel structured workshop and warehouse,canopy,packingsheds,corridors,studio light awning and greenhouse etc as the excellent light transmittance.

FRP plane skylightis the more strengthened, safety, and more econimal greenhouse panel with the properties of waterproof,good light transmittance,heat insulation,strong impact resistant,withstand extreme temperature.

Normal thinkness:1.2mm,1.5mm,2.0mm

FEATURES

1) The fiberglass content about 27%-30%.

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5) Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

SPECIFICATIONS

Thickness | Mesh size | Panel size | Open area | Weight |

(MM) | (MM) | (MM) | % | (kg/m2) |

25 | 38*38 | 1220*3660 | 68 | 12.5 |

1220*4076 | ||||

1220*4000 | ||||

30 | 38*38 | 1220*3660 | 68 | 14.75 |

1220*4000 | ||||

38 | 38*38 | 1007*4047 | 68 | 19.5 |

1220*3660 | ||||

1220*4000 | ||||

50.7 | 50.7*50.7 | 1220*3660 | 71 | 23.5 |

1220*4000 | ||||

30 | 19*19 | 1007*4007 | 40 | 18.1 |

38 | 19*19 | 1007*4007 | 40 | 23.5 |

PICTURES

- Q: How do FRP roofing panels compare to traditional roofing materials in terms of durability?

- FRP (Fiberglass Reinforced Plastic) roofing panels are known for their exceptional durability, making them a reliable alternative to traditional roofing materials. When compared to traditional materials like asphalt shingles or metal roofing, FRP panels offer several advantages in terms of durability. Firstly, FRP roofing panels are highly resistant to weather elements such as rain, snow, hail, and UV rays. The fiberglass reinforcement provides strength and prevents cracking or warping in extreme weather conditions. This durability allows FRP panels to maintain their structural integrity over time, providing long-lasting protection for a building. Moreover, FRP panels are resistant to corrosion and chemical damage, which is particularly beneficial in areas with high humidity or exposure to chemicals. Unlike metal roofing, which may rust or corrode over time, FRP panels retain their original strength and appearance. Another advantage of FRP roofing panels is their resistance to fire. Unlike traditional materials like wood or asphalt, which are highly flammable, FRP panels have excellent fire resistance properties. They are self-extinguishing and do not contribute to the spread of fire, making them a safer option for roofing. Furthermore, FRP panels are lightweight yet strong, making them easier to handle and install. Their lightweight nature reduces the strain on the building's structure while providing excellent durability. This can be particularly advantageous for large-scale roofing projects or when replacing existing roofs. In summary, FRP roofing panels offer superior durability compared to traditional roofing materials. Their resistance to weather elements, corrosion, chemicals, and fire make them a reliable choice for long-lasting protection. Additionally, their lightweight nature and ease of installation add to their appeal.

- Q: Can FRP roofing panels be installed on both residential and commercial buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on both residential and commercial buildings. FRP panels are versatile and can be used in a variety of applications, including roofing. They are lightweight, durable, and provide excellent resistance to weathering, UV radiation, and corrosion. These qualities make FRP roofing panels a suitable choice for both residential and commercial buildings. Additionally, FRP panels are available in various colors, shapes, and sizes, allowing for customization to suit different architectural styles and design preferences.

- Q: Are FRP roofing panels suitable for industrial applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for industrial applications. They are highly durable, lightweight, and resistant to corrosion, making them ideal for industrial settings where there may be exposure to harsh chemicals, extreme temperatures, or heavy machinery. Additionally, FRP roofing panels offer excellent strength and insulation properties, providing protection and energy efficiency for industrial buildings.

- Q: Are FRP roofing panels cost-effective?

- Yes, FRP roofing panels are considered cost-effective for several reasons. Firstly, FRP panels are highly durable and have a long lifespan, which means they require minimal maintenance and replacement. This can significantly reduce long-term costs associated with repairs and replacements. Additionally, FRP panels are lightweight and easy to install, resulting in reduced labor costs during the installation process. Their lightweight nature also makes them more cost-effective to transport, as they require less fuel and manpower for transportation. Furthermore, FRP roofing panels have excellent thermal insulation properties, which can help reduce energy consumption and lower heating and cooling costs. This can result in significant savings on utility bills over time. Another cost-saving aspect of FRP roofing panels is their resistance to corrosion, UV rays, and other environmental factors. This means that they do not deteriorate easily, reducing the need for frequent repairs or replacements. Overall, while FRP roofing panels may have a slightly higher upfront cost compared to some traditional roofing materials, their long-term cost-effectiveness due to durability, low maintenance requirements, energy efficiency, and resistance to environmental factors make them a worthwhile investment.

- Q: Can FRP roofing panels withstand extreme weather conditions?

- Yes, FRP roofing panels are designed to withstand extreme weather conditions. They are highly durable and resistant to harsh elements like rain, wind, snow, and UV radiation. Additionally, FRP panels have excellent thermal insulation properties and are resistant to corrosion, making them a reliable choice for various climates and weather conditions.

- Q: Can FRP roofing panels be installed on existing roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on existing roofs. However, certain factors need to be considered before installation. Firstly, the condition of the existing roof needs to be assessed to ensure it is structurally sound and can support the weight of the FRP panels. Additionally, the compatibility of the existing roof material with FRP panels should be evaluated. If the existing roof is in good condition and compatible with FRP panels, the installation process typically involves cleaning the roof surface, removing any loose or damaged materials, and preparing it for the installation of the FRP panels. This may include applying primer or adhesive to the roof surface to improve adhesion. It is important to follow the manufacturer's guidelines and recommended installation methods to ensure a proper and secure installation. Additionally, it is advisable to consult with a professional roofing contractor or FRP panel supplier for expert advice and assistance during the installation process. Overall, while FRP roofing panels can be installed on existing roofs, it is crucial to consider various factors and consult professionals to ensure a successful installation that meets all safety and performance requirements.

- Q: Can FRP roofing panels be used for patio covers?

- Yes, FRP roofing panels can be used for patio covers. FRP (Fiberglass Reinforced Plastic) panels are durable, lightweight, and provide excellent protection against the elements. They are often used in roofing applications, including patio covers, due to their strength, resistance to corrosion, and ability to withstand harsh weather conditions.

- Q: Are FRP roofing panels compatible with rooftop gardens or green roof systems?

- Rooftop gardens or green roof systems can be perfectly paired with FRP roofing panels. FRP, an abbreviation for Fiber Reinforced Polymer, is a strong and lightweight material capable of withstanding the weight of a green roof system. These panels offer exceptional insulation and can be designed with a high load-bearing capacity, making them ideal for supporting the extra weight of soil, plants, and water in a rooftop garden. Furthermore, FRP panels possess resistance against moisture, UV rays, and chemicals, all of which are crucial considerations in the implementation of a green roof system. All in all, FRP roofing panels are an excellent option for incorporating rooftop gardens or green roof systems into buildings.

- Q: Are FRP roofing panels compatible with rooftop solar water heaters?

- Yes, FRP roofing panels are generally compatible with rooftop solar water heaters. FRP panels are lightweight, durable, and resistant to corrosion, making them suitable for supporting the weight of solar water heaters. Additionally, FRP panels are often translucent, allowing sunlight to reach the solar collectors beneath, thus maximizing energy efficiency.

- Q: Are FRP roofing panels resistant to warping or sagging due to heat?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their high resistance to warping or sagging due to heat. The composition of FRP panels includes fiberglass reinforcement, which provides exceptional strength and stability even under high temperatures. This reinforcement helps prevent the panels from warping or sagging, ensuring their long-term durability and performance. In addition to the fiberglass reinforcement, FRP panels are also designed to have low thermal expansion properties. This means that they have minimal expansion or contraction with temperature changes, reducing the chances of warping or sagging. The panels are engineered to withstand the heat and maintain their shape and structural integrity, making them a reliable choice for roofing applications. It is worth noting that while FRP panels are resistant to warping or sagging due to heat, proper installation and maintenance are crucial to ensure their longevity. Following manufacturer guidelines and regularly inspecting and maintaining the roof will help maximize the performance and lifespan of the FRP roofing panels.

Send your message to us

FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords