Translucent Polyethylene FRP Plastic Sheet Roof Skylight Panel Soundproof Steel Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANY INFORMATION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china buiding materials industry. Established in 1984,CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

INTRODUCTION

A roof is part of a building envelope. It is the covering on the uppermost part of a building or shelter which provides protection from animals and weather, notably rain or snow, but also heat, wind and sunlight. The word also denotes the framing or structure which supports that covering.

The characteristics of a roof are dependent upon the purpose of the building that it covers, the available roofing materials and the local traditions of construction and wider concepts of architectural design and practice and may also be governed by local or national legislation. In most countries a roof protects primarily against rain. A verandah may be roofed with material that protects against sunlight but admits the other elements. The roof of a garden conservatoryprotects plants from cold, wind, and rain, but admits light.

A roof may also provide additional living space, for example a roof garden.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Place of Origin: | Hebei, China(Mainland) | Brand Name: | CMAX |

| Model Number: | 2.5 mm | Material: | Synthetic Resin, Synthetic resin & ASA |

| Type: | Double Roman Tiles | Thickness: | 3 mm, 2.5mm, 2.3mm |

| Color: | Red or as customer require | Length: | as customer require |

| Width: | 1 meter | Density: | 1.685 g/CuNaN |

| Fire prevention: | B1 grade | Wave height: | 87.5px |

| Wave spacing: | 500px | Effecitve width: | 0.9m |

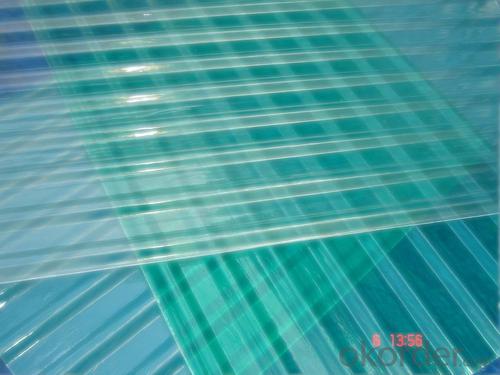

PICTURES

- Q: Are FRP roofing panels resistant to warping or deformation from heavy loads?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are highly resistant to warping or deformation from heavy loads. The strong and durable nature of FRP panels allows them to withstand heavy loads without compromising their structural integrity, making them an excellent choice for applications that require load-bearing capabilities.

- Q: Are FRP roofing panels resistant to discoloration from air pollution?

- FRP roofing panels exhibit remarkable resistance to discoloration caused by air pollution. Renowned for their durability and ability to withstand diverse environmental elements, including air pollution, FRP panels are equipped with an outer gel coating that serves as a safeguard against fading or discoloration resulting from exposure to airborne pollutants. Consequently, FRP roofing panels prove to be an exceptional option for regions plagued by substantial levels of air pollution, as they retain their original hue and aesthetic appeal over an extended duration.

- Q: Are FRP roofing panels resistant to damage from high temperatures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to damage from high temperatures. They are designed to withstand extreme heat without warping, melting, or deteriorating, making them an ideal choice for areas with hot climates or industries that involve high-temperature processes.

- Q: Do FRP roofing panels require any specific safety measures during installation?

- During the installation of FRP roofing panels, specific safety measures are required. Take note of the following important safety precautions: 1. Personal Protective Equipment (PPE): It is necessary for installers to wear appropriate safety gear such as safety glasses, gloves, and non-slip footwear. This will safeguard them against potential hazards like sharp edges or falling debris. 2. Ensuring a Safe Work Environment: Prior to commencing the installation, make sure the work area is free from any obstructions or tripping hazards. Maintaining good housekeeping practices is crucial to minimize the risk of accidents. 3. Fall Protection: If the installation involves working at heights, implement fall protection measures such as harnesses, guardrails, or safety nets. Installers should receive proper training on the use of fall protection equipment. 4. Proper Lifting Techniques: FRP roofing panels can be heavy, so it is important to use proper lifting techniques to prevent strains or injuries. Depending on the weight and size of the panels, team lifting or mechanical lifting devices may be necessary. 5. Power and Tool Safety: If power tools are used during installation, ensure that they are operated according to the manufacturer's instructions and only by trained personnel. Adhere to electrical safety precautions such as using grounded tools and avoiding wet conditions. 6. Weather Conditions: Weather conditions can affect the safety of the installation, particularly when working at heights. Installers should be mindful of potential hazards like strong winds, rain, or lightning and take appropriate precautions, including rescheduling the work if necessary. 7. Training and Supervision: Proper training in the installation techniques and safety measures specific to FRP roofing panels is essential for all installers. Regular supervision and communication regarding safety practices can prevent accidents and maintain a safe working environment. By adhering to these safety measures, the risk of accidents or injuries during the installation of FRP roofing panels can be significantly reduced, ensuring the safety of the installers and the overall success of the project.

- Q: What is the expected lifespan of FRP roofing panels?

- Various factors, such as panel quality, installation process, and environmental conditions, can affect the expected lifespan of FRP roofing panels. On average, these panels can last anywhere from 20 to 30 years. FRP, or fiberglass reinforced plastic, is a lightweight and durable material that resists corrosion, UV radiation, and extreme weather conditions. It is a popular choice for roofs, particularly in areas with harsh climates. To maximize the lifespan of FRP roofing panels, proper installation and regular maintenance are essential. Regular inspections and cleaning can prevent the buildup of debris, which can cause panel deterioration. Applying a protective coating or sealant can also enhance longevity by providing an extra layer of protection against wear and tear. It's worth noting that the specific brand or manufacturer of FRP roofing panels can also influence their lifespan. Some manufacturers offer extended warranties, indicating their confidence in the durability of their products. Therefore, it's advisable to consult with a reputable supplier or manufacturer to determine the expected lifespan of specific FRP roofing panels before making a purchase.

- Q: Can FRP roofing panels be used in historical preservation projects?

- Historical preservation projects can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. FRP roofing panels serve as a versatile and durable roofing material that offers numerous benefits in these projects. To begin with, FRP roofing panels have the capability to mimic the appearance of traditional roofing materials like clay tiles or wood shakes. This allows historical buildings to retain their original aesthetic while taking advantage of the enhanced durability and longevity provided by FRP panels. Moreover, FRP roofing panels are lightweight and easy to install, making them suitable for historical buildings with delicate structures. They exert less pressure on the structure compared to heavier roofing materials, thereby reducing the risk of damage or structural issues. Additionally, FRP roofing panels exhibit high resistance to corrosion, moisture, and UV radiation. This resistance ensures that the roof of the historical building remains protected and extends its lifespan, thereby decreasing the need for frequent repairs or replacements. Furthermore, FRP panels possess excellent insulation properties, resulting in energy efficiency benefits for historical buildings. This insulation helps regulate temperature, thereby reducing heating and cooling costs and enhancing the overall sustainability of the building. Lastly, FRP roofing panels are low maintenance and have a long service life. This attribute is crucial in historical preservation projects as it minimizes the need for ongoing maintenance and facilitates the preservation of the building's historical integrity. In conclusion, FRP roofing panels represent a suitable and advantageous choice for historical preservation projects. Their ability to replicate traditional roofing materials, lightweight nature, durability, resistance to various elements, insulation properties, and low maintenance make them a viable option for preserving historical buildings while ensuring their long-term protection and sustainability.

- Q: Can FRP roofing panels be used for car wash structures or detailing bays?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels can be used for car wash structures or detailing bays. FRP panels are known for their durability, resistance to corrosion, and ability to withstand harsh environments. These qualities make them suitable for car wash structures and detailing bays where they may come into contact with water, chemicals, and other potentially damaging substances. Additionally, FRP panels are lightweight, easy to install, and cost-effective, making them a popular choice for such applications.

- Q: Are FRP roofing panels resistant to chemical exposure in industrial environments?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally highly resistant to chemical exposure in industrial environments. FRP panels are known for their excellent corrosion resistance and can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and fuels. They are commonly used in industrial settings such as chemical plants, refineries, and manufacturing facilities where there is a high risk of chemical exposure. FRP panels are designed to be chemically inert, meaning they do not react with or degrade in the presence of chemicals. This resistance to chemical exposure makes FRP roofing panels a durable and reliable choice for protecting industrial buildings and equipment from the potentially damaging effects of chemical substances. However, it is important to note that the specific performance of FRP panels may vary depending on the type and concentration of chemicals involved, so consulting with the manufacturer or a professional in the field is advised for specific application requirements.

- Q: Can FRP roofing panels be used for architectural designs?

- Yes, FRP roofing panels can be used for architectural designs. These panels offer a wide range of design possibilities due to their flexibility, durability, and versatility. FRP roofing panels can be molded into various shapes, sizes, and colors, allowing architects to create unique and visually appealing designs. Additionally, FRP panels are lightweight, making them suitable for both small and large-scale architectural projects.

- Q: Are FRP roofing panels prone to cracking from heavy loads?

- FRP roofing panels are renowned for their strength and durability, making them less susceptible to cracking under heavy loads compared to alternative roofing materials. However, it is crucial to acknowledge that the resistance to cracking can vary depending on the thickness, quality, and installation technique of the FRP panels. Typically, FRP roofing panels are engineered to endure substantial loads, such as snow accumulation, foot traffic, and occasional impacts. They are crafted utilizing a combination of robust fiberglass reinforcement and a resin matrix, ensuring exceptional structural integrity. This composition effectively distributes the load evenly across the panel's surface, thereby diminishing the likelihood of cracking when confronted with heavy loads. Nonetheless, it is always advisable to adhere to the load-bearing capacities stipulated by the manufacturer. Should the FRP panels be subjected to excessive loads exceeding their intended capacity, there exists the potential for cracking or other forms of structural damage. Thus, it is crucial to ensure proper installation of the panels and equitable distribution of any heavy loads to minimize the occurrence of cracking. Regular inspections and maintenance of the FRP roofing panels are also imperative to identify any indications of wear, damage, or stress that may lead to cracking. Immediate repairs or reinforcements must be carried out upon detecting any issues to prevent further damage and preserve the longevity of the roofing system. In conclusion, although FRP roofing panels generally exhibit reduced susceptibility to cracking under heavy loads, it is essential to consider their specific design, thickness, and installation quality, as well as adhere to load-bearing guidelines to mitigate potential risks.

Send your message to us

Translucent Polyethylene FRP Plastic Sheet Roof Skylight Panel Soundproof Steel Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords