FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

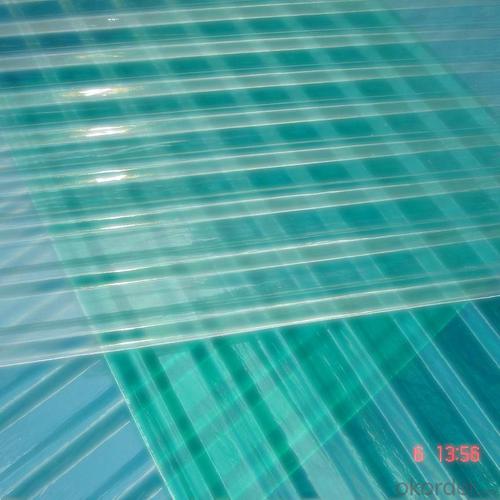

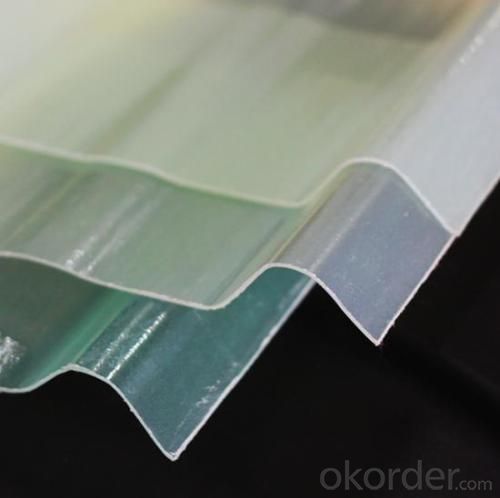

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Products Name | Manufacture corrugated metal roof / zinc roof / roofing sheet for houses |

THICKNESS | 0.14-0.5MM |

WIDTH | 765MM-->665MM 900MM-->800MM 1000MM-->900MM |

ALUZINC | ALUZINC ROOFING CAN BE SUPPLIED. |

MATERIAL | SGCC,DC51D,DX51D,DX52D |

SPANGLE | ZERO, REGULAR, NORMAL,BIG SPANGLE. |

SURFACT TREATMENT | CHROMATED, OILED, NON-OILED, DRY. |

HARDNESS | SOFT, HARD, FULL HARD. |

PICTURES

- Q: Can FRP roofing panels be used for zoos?

- Zoos can utilize FRP roofing panels due to their durability, strength, and resistance to environmental elements. These panels are suitable for various applications, including zoos, where animal safety is paramount. When it comes to zoos, the use of FRP roofing panels brings several advantages. Firstly, they are lightweight yet robust, ensuring a secure and dependable roofing solution, especially in areas prone to heavy snow loads or strong winds. Secondly, FRP panels possess exceptional resistance against UV radiation, preventing fading, discoloration, or degradation caused by prolonged sun exposure. This is vital for maintaining the zoo's aesthetics and ensuring visually pleasing enclosures for the animals. Furthermore, FRP roofing panels exhibit low thermal conductivity, which aids in regulating the temperature within the enclosures. This contributes to a more comfortable and controlled environment for the animals. Additionally, these panels provide excellent insulation, resulting in energy efficiency and reduced heating or cooling costs. Moreover, FRP roofing panels offer a wide range of colors, textures, and designs, enabling zoo designers to create visually appealing enclosures that mimic natural habitats. This enhances the overall experience for visitors while providing a more stimulating and enriching environment for the animals. In conclusion, FRP roofing panels serve as a versatile and reliable roofing solution for zoos. Their durability, resistance to environmental factors, and aesthetic options make them a suitable choice for creating safe and visually appealing enclosures for animals.

- Q: Can FRP roofing panels be installed over existing roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed over existing roofs in some cases. However, it is important to consider a few factors before proceeding with the installation. Firstly, the condition of the existing roof should be assessed. If the roof is severely damaged or has structural issues, it may not be suitable for installing FRP panels over it. It is recommended to have a professional roofer inspect the existing roof to determine its suitability for installation. Secondly, the weight of the FRP panels should be considered. If the existing roof is unable to support the additional weight of the panels, it may lead to further damage or even collapse. Again, a professional should be consulted to evaluate the load-bearing capacity of the existing roof. Additionally, the compatibility of the FRP panels with the existing roof should be checked. Different roofing materials may have different expansion and contraction rates, and this could cause issues if the panels are not properly installed or if they do not align with the existing roof structure. Lastly, local building codes and regulations should be considered. Some jurisdictions may have specific requirements or restrictions for installing new roofing materials over existing roofs. It is crucial to comply with these regulations to ensure the safety and integrity of the roof. In summary, while it is possible to install FRP roofing panels over existing roofs, it is essential to assess the condition of the existing roof, evaluate its weight-bearing capacity, check compatibility, and comply with local regulations. Consulting with a professional roofer is highly recommended to ensure a successful and safe installation.

- Q: Can FRP roofing panels be used for curved roofs?

- Yes, FRP roofing panels can be used for curved roofs. FRP panels are flexible and can be easily molded to fit the desired shape of a curved roof. This makes them a suitable choice for curved roof applications, providing both durability and aesthetic appeal.

- Q: Are FRP roofing panels compatible with solar panels?

- FRP roofing panels, indeed, are compatible with solar panels. They offer a robust and enduring roofing material that can bear the weight of solar panels. Moreover, the smooth surface of FRP panels enables a seamless installation and mounting process for solar panels. Additionally, the translucent quality of FRP panels permits the passage of light, thereby maximizing sunlight exposure and enhancing the efficiency of solar panels. In summary, FRP roofing panels provide a fitting and appropriate platform for the installation of solar panels.

- Q: Are FRP roofing panels prone to cracking or warping over time?

- FRP roofing panels, renowned for their durability and resistance to cracking or warping, are constructed using a blend of fiberglass and plastic resins. This unique combination grants them exceptional strength and stability. One of the key benefits of FRP roofing panels lies in their ability to endure harsh weather conditions, including extreme temperatures, strong winds, and heavy rainfall. Unlike other roofing materials, FRP panels do not significantly expand or contract with temperature changes, thereby averting cracking or warping. Moreover, FRP panels are engineered to be lightweight yet robust, rendering them less susceptible to damage from external forces. This strength and rigidity enable the panels to maintain their shape and integrity over time, further minimizing the risk of cracking or warping. Nevertheless, it is crucial to acknowledge that the longevity and durability of FRP roofing panels can be influenced by various factors, such as the quality of materials, proper installation, and regular maintenance. Inferior or substandard panels may exhibit a greater propensity for cracking or warping. Similarly, incorrect installation or neglecting necessary maintenance, such as keeping the panels free of debris, can compromise their structural integrity. In conclusion, when FRP roofing panels are manufactured, installed, and maintained correctly, they possess a well-established reputation for being highly resistant to cracking or warping over time. Nonetheless, it is always prudent to seek guidance from professionals and adhere to the manufacturer's guidelines to ensure optimal performance and longevity of the panels.

- Q: Can FRP roofing panels be used in areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with heavy snowfall. FRP roofing panels are known for their durability and strength, making them suitable for withstanding heavy snow loads. However, it is important to consider a few factors when using FRP roofing panels in areas with heavy snowfall. Firstly, the pitch or slope of the roof should be taken into account. A steeper pitch allows snow to slide off more easily, reducing the risk of accumulation and potential damage to the roofing panels. Additionally, proper installation techniques should be followed to ensure that the panels are securely fastened and sealed to prevent any snow or water infiltration. It is also advisable to regularly remove accumulated snow from the roof to prevent excessive weight on the panels. This can be done using safe and appropriate snow removal techniques, such as using a roof rake or hiring professionals who are knowledgeable in snow removal. Lastly, it is essential to choose FRP roofing panels that are specifically designed and rated for heavy snow loads. These panels are typically reinforced and have higher load-bearing capacities, ensuring they can withstand the weight and stress caused by heavy snow accumulation. Overall, with proper installation, regular maintenance, and appropriate panel selection, FRP roofing panels can be effectively used in areas with heavy snowfall.

- Q: Can FRP roofing panels be used for skylights in educational institutions?

- Yes, FRP (fiberglass reinforced plastic) roofing panels can be used for skylights in educational institutions. FRP panels are lightweight, durable, and have excellent light transmission properties, making them an ideal material for skylights. They are also resistant to UV rays, weathering, and impact, ensuring longevity and low maintenance costs. Additionally, FRP panels can be custom-made to fit any size or shape, allowing for flexibility in design and installation. The use of FRP skylights in educational institutions can enhance natural lighting and create a more conducive learning environment for students.

- Q: Do FRP roofing panels come in different colors?

- Yes, FRP roofing panels come in different colors.

- Q: Can FRP roofing panels withstand hail damage?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are designed to withstand hail damage. The fiberglass reinforcement in the panels provides them with high strength and durability, making them resistant to impact from hailstones. Additionally, FRP roofing panels are known for their flexibility, which allows them to absorb the impact of hailstones without cracking or shattering. They are also resistant to corrosion, which further enhances their ability to withstand hail damage. However, it is important to note that the extent of hail damage can still depend on the size and intensity of the hailstones, as well as other factors such as the panel thickness and installation quality. Therefore, while FRP roofing panels are generally capable of withstanding hail damage, it is always recommended to consult with a professional and consider additional protective measures if you are located in an area prone to severe hailstorms.

- Q: Do FRP roofing panels have any specific installation requirements for ventilation?

- Yes, FRP roofing panels typically require proper ventilation during installation to prevent condensation buildup and ensure optimal performance. Ventilation helps to release moisture and maintain a balanced temperature, which is crucial for preserving the integrity of the panels and preventing potential damage.

Send your message to us

FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords