SMC Sheet - High Strength Colored Hydraulic/SMC Sheet Press Machine FRP Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

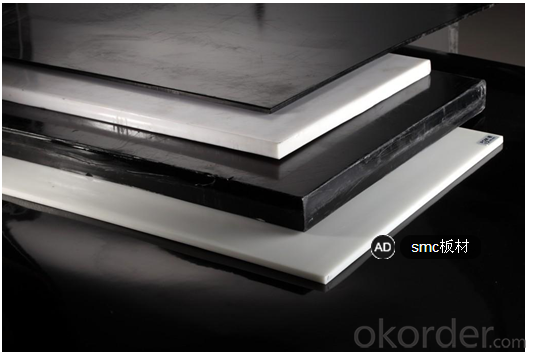

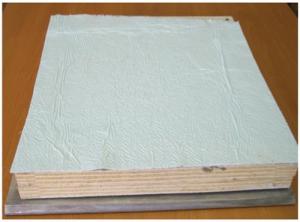

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

Higher mechanical strength

Excellent leak-proof electrical

Excellent thermal stability, chemical corrosion resistance

Low water absorption, good dimensional stability, war page small

Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Basic information | |

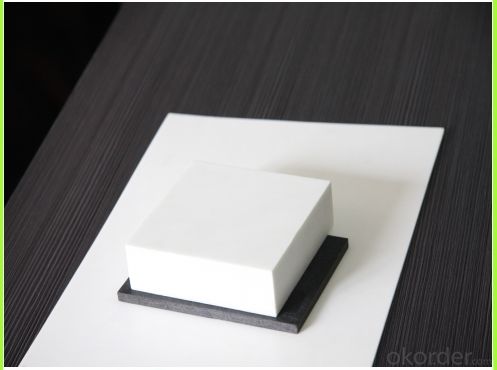

Product name | SMC cutting board |

SMC cutting board | |

Item NO. | SMC-S2005 |

Optional type | Sheet, Film, Rod |

Material | Phenolic resin and cellulose paper |

Grade | Grade A |

H.S code | 39209400 |

Certificate | SGS, Rosh |

Environment | Recyclable |

Sample | For free, but customer pays the freight. |

Similar products | Phenolic cotton cloth laminates |

Specification | |

Density | 1.45g/cm3 |

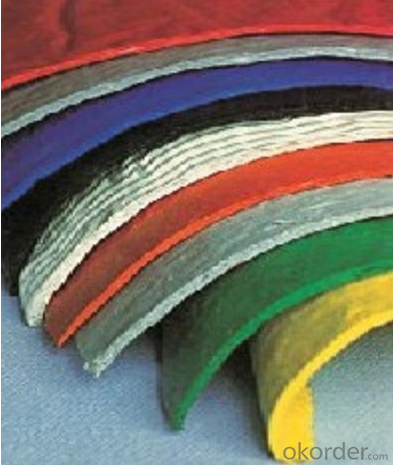

Color | Orange, black |

Sheets Thickness | 2.0-50mm |

Stock Size | 980*1980mm,1020*1220mm,1020*2040mm,1220*2440mm |

Rods Diameter | 10-200mm |

Stock Size (Length) | 1000mm,can be customized |

Formation methods | High temperature and high pressure |

Delivery details | |

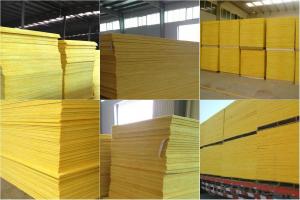

Stock | 40Ton |

Packaging | 1. Wooden pallet with carton. |

2. Plastic pallet with carton. | |

3. Wooden pallet with wooden case. | |

4. According to customer requirements. | |

Delivery | 1. Stock size 3-5 working days. |

2. Custom size 8-15 working days. | |

Attribute parameter | |

Adhesive strength | ≥ 280N |

Vertical layers to the flexural strength | ≥ 190MPa |

Layer parallel to the breakdown voltage | ≥ 10kV |

Vertical layer to the electrical intensity ( 2mm) | ≥ 12MV / m |

Property | |

1. Non-absorbent, non-conductive | |

2. High strength , good insulation properties | |

3. Wear-resisting and thermos table characteristic | |

4. Excellent electrical, mechanical and processing properties | |

Applications | |

1. Used in fixture plate , mold plywood, countertops grinding plate, packaging machines,comb,etc | |

2. Used in the mechanical performance requirements, electrical equipment and insulating structural parts | |

Advantage

Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

Absolute seal waterproof performance, corrosion resistance

Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

(3) The engine cover under parts such as air conditioner shell: wind shield, the intake manifold cover, Fan vanes ring, heater cover, tank parts, brake system components, and the Battery bracket, engine noise barriers and so on

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

3. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

4. Application in architectural engineering

Water tank, bathes the thing, purifies the trough, building templates, storage component

5. Application in the explosion-proof electrical equipment shell

6. Applications in wireless communications

7. Application of in the bathroom

8. Application in ground

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

PACAKGE

- Q: What's the difference between a ductile iron well and a composite resin manhole cover?

- Ductile iron wells: cast iron, light weight only about 1/3 of the easy transportation, installation and maintenance, greatly reduce the labor intensity of workers, natural security: according to the needs of customers is also equipped with anti-theft lock structure, to achieve this property.

- Q: The difference between glass fiber reinforced plastic antenna and cannon antenna

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- Equipment: simple, but also the main features of plastic equipment. The two halves of the platen are joined together to heat and pressurize the material into a predetermined shape. Most pressing processes are hydraulically operated; pneumatic operations are also used. On the two plate moves in the 4 corner posts up and down under pressure. According to the size of press and mould equipment, the pressure is usually 20 - 1000 tons. The size of the platen is usually 8 inches, 2 to 5 feet, 2.There are different degrees of automation in the mold release after charging and curing. The most modern hydraulic press is often used. Previous simple systems include temperature control, pressure control, stop pressure control, and time control. Modern equipment is controlled by more advanced microprocessors. For thinner products, a heating cylinder or belt heater can be used in the plate. For deeper parts, use a cylindrical electric heater, steam heating or hot oil heating system. There are several kinds of pressure heating system used in plastic with uniform temperature steam heating mode, but the heating temperature limit below 350 DEG F; barrel heating or other heating (heating coil, heating etc.) is relatively clean, easy to maintain, with more universal; oil heating, because the heating medium circulation is stable, so the uniform heating. Now there are many new heating methods, hot water heating, similar to hot oil heating, heating medium, one water, one gas combustion, continuous cycle, can provide higher plastic temperature.

- Q: Is the quality of the resin wall the same?

- From the installation form, it is divided into the gusset and the panel, the gusset plate is installed with the keel, and the panel is pasted on the wall with glue.

- Q: Which is good for SMC composites and honeycomb composites?

- The method of forming a honeycomb structure of a composite material suppresses the sheet material into a corrugated form and then welds or sticks together to form a honeycomb structure;

- Q: Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- I don't quite understand your question. SMC has only one manufacturer. I'm the agent of SMC. You don't know much about it

- Q: What is a sheet of material? Is it plastic? What is it used for?

- The sheet refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. In the material industry, SMC is commonly known as sheet material, and the full name of Chinese is: sheet molding plastics. The utility model relates to a premix for molding. In the glass fiber reinforced plastic industry, SMC is widely used. The large areas of sheet materials, such as automobile shell, water tank, seat and so on, are generally molded by SMC compression and heating.

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC, which is composed of SMC, unsaturated polyester resin, glass fiber roving, and other materials with special equipment by SMC forming unit made of sheet, and then by thickening, cut, put on metal mold by high pressure and high temperature curing made.

- Q: How is glass fiber reinforced plastic water tank made?

- This is really hard to understand, but I was in the five Yi bought water tank, good quality

- Q: Are SMC tablets harmful to the body? Our factory produces SMC. I have contact every day. Is there any odor that is harmful to my health?

- The state is recognized and safe.

Send your message to us

SMC Sheet - High Strength Colored Hydraulic/SMC Sheet Press Machine FRP Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords