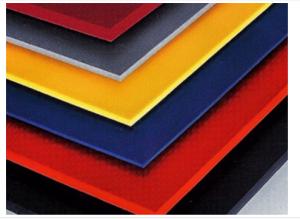

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC for FRP Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

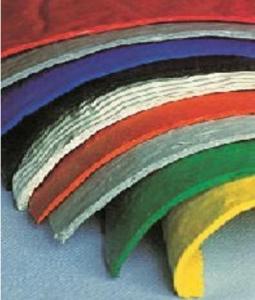

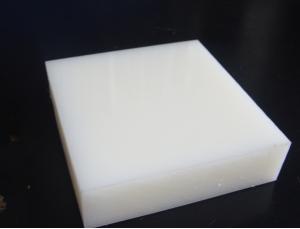

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

Higher mechanical strength

Excellent leak-proof electrical

Excellent thermal stability, chemical corrosion resistance

Low water absorption, good dimensional stability, war page small

Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Basic information | |

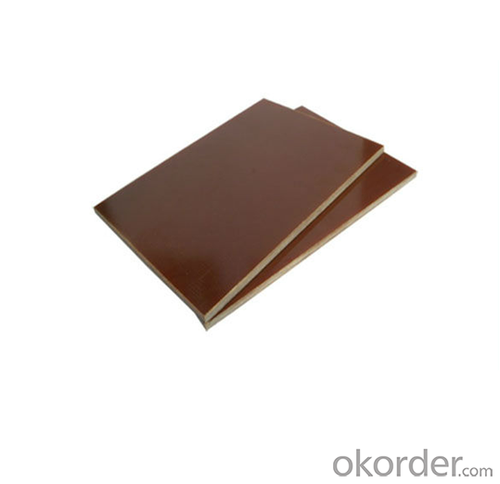

Product name | SMC cutting board |

SMC cutting board | |

Item NO. | SMC-S2005 |

Optional type | Sheet, Film, Rod |

Material | Phenolic resin and cellulose paper |

Grade | Grade A |

H.S code | 39209400 |

Certificate | SGS, Rosh |

Environment | Recyclable |

Sample | For free, but customer pays the freight. |

Similar products | Phenolic cotton cloth laminates |

Specification | |

Density | 1.45g/cm3 |

Color | Orange, black |

Sheets Thickness | 2.0-50mm |

Stock Size | 980*1980mm,1020*1220mm,1020*2040mm,1220*2440mm |

Rods Diameter | 10-200mm |

Stock Size (Length) | 1000mm,can be customized |

Formation methods | High temperature and high pressure |

Delivery details | |

Stock | 40Ton |

Packaging | 1. Wooden pallet with carton. |

2. Plastic pallet with carton. | |

3. Wooden pallet with wooden case. | |

4. According to customer requirements. | |

Delivery | 1. Stock size 3-5 working days. |

2. Custom size 8-15 working days. | |

Attribute parameter | |

Adhesive strength | ≥ 280N |

Vertical layers to the flexural strength | ≥ 190MPa |

Layer parallel to the breakdown voltage | ≥ 10kV |

Vertical layer to the electrical intensity ( 2mm) | ≥ 12MV / m |

Property | |

1. Non-absorbent, non-conductive | |

2. High strength , good insulation properties | |

3. Wear-resisting and thermos table characteristic | |

4. Excellent electrical, mechanical and processing properties | |

Applications | |

1. Used in fixture plate , mold plywood, countertops grinding plate, packaging machines,comb,etc | |

2. Used in the mechanical performance requirements, electrical equipment and insulating structural parts | |

Advantage

Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

Absolute seal waterproof performance, corrosion resistance

Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

(3) The engine cover under parts such as air conditioner shell: wind shield, the intake manifold cover, Fan vanes ring, heater cover, tank parts, brake system components, and the Battery bracket, engine noise barriers and so on

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

3. Application in rail vehicle

SMC railway vehicles, window frames, bathroom components, seat, coffee table tops, SMC compartment wall and SMC roof

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

PROCESS

FACTORY

PACAKGE

- Q: Where are the differences between the products made of stone and resin?

- If the quality of the tree ester products, the release of toxic substances will be more, longer.Of course, the stone now has man-made, with resin produced all kinds of marble and sheet metal.

- Q: The difference between glass fiber reinforced plastic antenna and cannon antenna

- FRP antenna: SMC, which is composed of SMC, unsaturated polyester resin, glass fiber roving, and other materials with special equipment by SMC forming unit made of sheet, and then by thickening, cut, put on metal mold by high pressure and high temperature curing made. SMC and its molded products as a new glass fibre reinforced plastics, glass steel, the processing methods can be divided into: hand molding, injection molding, paste pultrusion, winding molding, resin transfer molding, molding and other kinds of processing methods.

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- The obvious advantage of plastic forming of thermosetting materials is the simplicity of the system. Place the material in a heated cavity and keep it to the desired time. Because the process is simple and the cost is low. Additives and reinforcing agents are irregular and have better strength. Since there is no gate and runner, no waste of materials, mold almost no maintenance. The parts have good uniformity, no casting and flowing marks, and reduce the cost of modification. According to the structure of the product and the application characteristics of the plastic, we can use full pressure mold, semi pressure mold and closed die (see the article about the plastic mould).

- Q: What are the raw materials for composite manhole covers?

- Because the SMC polymer resin composite covers are made of resin and SMC polymer sheet pressing, without reinforcement than usual covers light weight 2/3, but this kind of SMC polymer resin composite covers and not because of its weight and reduce its carrying capacity, SMC polymer resin composite well cover bearing is three times that of ordinary resin composite manhole cover bearing, up to 90 tons

- Q: What material is SMC? Can it replace ceramics? Can it be made into toilets, basins, urinals and so on?

- SMC composite and its SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability and chemical resistance. Therefore, SMC products have a wide range of applications, mainly in the following areas of application: SMC1. Application of electrical industry. 2. Application in automobile industry. 3. Applications in railway vehicles. 4 、 application in communication engineering. 5, explosion-proof electrical equipment, such as shell applications.

- Q: Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- The requirement of BMC SMC process is that the material can be thickened, and the thickening properties of unsaturated resins are better

- Q: In recent years, what new materials have come into use in the automotive interior, or in the future?

- LFT is a kind of advanced fiber reinforced lightweight materials in the field, with design, low density, high specific strength, high specific modulus and strong impact resistance and other characteristics, it appears to Aluminum Alloy, fiber reinforced thermoset composites poses huge challenges, and gradually become the mainstream material production of auto parts.LFT Long-Fiber Reinforce is English Thermoplastic, Chinese for long fiber reinforced thermoplastic plastics, used to call the long fiber reinforced thermoplastic composites, it is a kind of advanced fiber reinforced lightweight polymer material field.

- Q: How do you measure the excess of the compound in the house?

- SMC uses roving SMC, a sheet molding compound, for automotive parts, bathtubs, water tanks, purifying tanks, seats, etc..

- Q: How is glass fiber reinforced plastic water tank made?

- FRP hand lay up tank: made of resin glass cloth paste hand processing tank frame surface

- Q: Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- SMC bridge, molding process, mass or sheet, high price. Use in high-speed rail, subway and other demanding occasions.

Send your message to us

SMC Sheet - 1.0mm Thickness Strong Fire Resistance Colorful SMC for FRP Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches