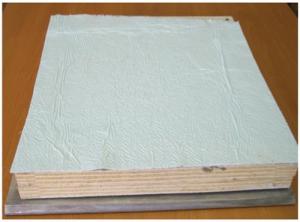

SMC Sheet Faced Glass Rock Wool Pipe/White Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

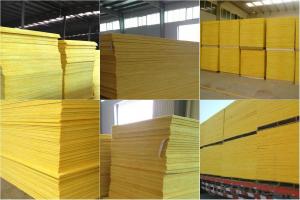

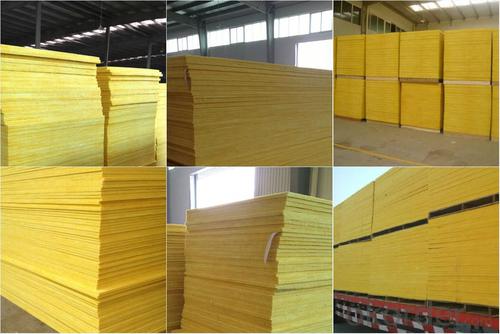

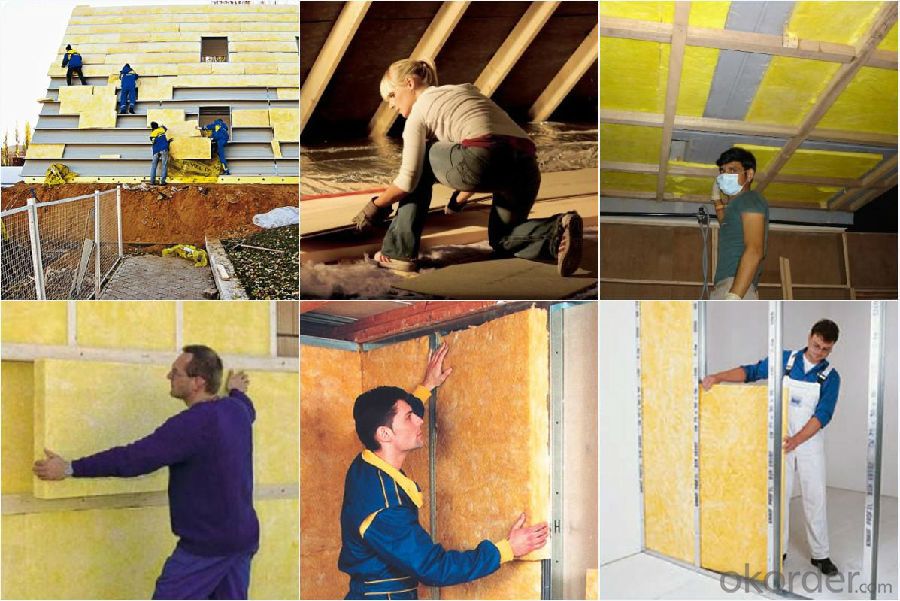

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Performance: high / low temperature resistance, oil resistance, fuel resistance,

Weather resistance, tolerance, etc.

There are a lot of practical use - rockwool products; the following are some of the major areas:

In - rockwool thermoacoustic field used for various types of buildings and the use of thermal insulation, such as housing, Department store,

Office buildings, stadiums, airports, etc..

In the insulation of industrial plants and machinery systems, etc.:

Cool store.

Refinery.

Chemical and petrochemical plant.

Central air-conditioning

Hot water and chilled water system.

For industrial purposes, - rockwool used in many industries:

Industrial furnaces and ovens.

It is widely used in heat preservation and industrial plants, prefabricated houses, portable cabins, warehouses, public facilities, exhibition centers, large shopping centers, the sound absorption, as well as a variety of indoor amusement parks, sports venues, etc..

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Where are the differences between the products made of stone and resin?

- If the quality of the tree ester products, the release of toxic substances will be more, longer.Of course, the stone now has man-made, with resin produced all kinds of marble and sheet metal.

- Q: Is the gas released from the heating of the SMC sheet poisonous?

- If unsaturated polyester resin is not doped with toxic solvents, the gases usually released after heating are not poisonous.

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- In recent years, press molding has been applied to thermosetting blends such as urea formaldehyde plastics, phenolic resins, epoxy resins, melamine resins, and rubber. Although some materials are available for injection molding, compression molding is still very common. Die casting material is more flexible than plastic material. Many thermosetting materials with high impact (1.0ft lb) and good notched impact strength retention, only in the limit under pressure will flow.

- Q: Does floor heating emit toxic gas?

- One check: check the product radioactive test report, see if the radioactive material is over standardTwo test: Please professionals with instruments for radioactive detection, to see whether and product radioactive test report in line with

- Q: In recent years, what new materials have come into use in the automotive interior, or in the future?

- In the past 20 years, the energy crisis and the rise in oil prices prompted the automobile lightweight gradually become the development trend of the new car, but also makes people to pay attention to the development of LFT low density material, LFT material properties and processing technology has also been improved.

- Q: How do you measure the excess of the compound in the house?

- SMC used in the manufacture of roving SMC sheet to cut the length of Lin (25mm), dispersed in resin paste and so on SMC roving requirement is short of good, low fuzz, excellent antistatic property, while cutting short shred will not adhere to the knife roller.

- Q: What is the difference between a gain fiberglass and an ordinary omnidirectional antenna?

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- (1) high tensile strength and small elongation (3%).(2) high elasticity and good rigidity.(3) the elongation within the elastic limit is large and the tensile strength is high, so the impact energy is large.(4) for inorganic fiber, with non flammable, chemical resistance.(5) water absorption is small.(6) the scale stability and heat resistance are excellent.(7) good processability, can be used as stock, bundle, felt, weaving and other forms of products.(8) transparent and permeable to light(9) the development of surface treatment agents with good resin properties.(10) the price is cheap.

- Q: Composite manhole cover or cast iron well cover?

- The new composite made of color composite manhole covers can reach 90 tons, which can be used as a substitute for cast iron covers, and the northern color is the patent name of Beijing Pan Asia Electric

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- Different grades of tree ester use different raw materials, new glycol, propylene glycol content of higher tree ester, made out of sheet pressure product brightness is better, but the higher the cost.

Send your message to us

SMC Sheet Faced Glass Rock Wool Pipe/White Pipe Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords