Rock Sol Insulation

Rock Sol Insulation Related Searches

Rocksol Insulation Rocksol Insulation Cost Rockwell Insulation Roxul Fireproof Insulation Home Insulation Insulation Wool Roof Foam Board Insulation Recycled Insulation Rec Solar Cells Rigid Calcium Silicate Insulation Exterior Rigid Foam Insulation Insulation Services Indoor Window Insulation Roof Insulation Materials Renusol Solar Mounting Systems Blanket Insulation For Steel Buildings Loft Insulation Foil Roof Insulation Materials Indoor Insulation Kaowool Insulation Open Cell Insulation Cellulose Insulation Ceramic Sheet Insulation Indoor Window Insulator Foam Core Insulation Exterior Polystyrene Insulation R13 Insulation Pe Insulation Best Home Insulation Marine Insulation MaterialRock Sol Insulation Supplier & Manufacturer from China

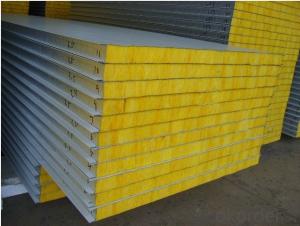

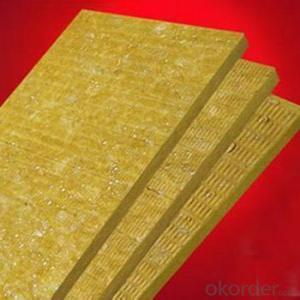

Rock Sol Insulation is a range of high-quality insulation products designed to provide effective thermal and acoustic insulation solutions for various applications. These products are engineered to meet the demands of both residential and commercial projects, ensuring optimal performance and durability. The insulation materials offered by Rock Sol are versatile and can be used in a wide array of scenarios, such as in walls, ceilings, and floors, to improve energy efficiency and reduce noise pollution. This makes them an ideal choice for contractors, builders, and homeowners looking to enhance the comfort and sustainability of their spaces.As a wholesale supplier, Okorder.com boasts a vast inventory of Rock Sol Insulation products, catering to the needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Rock Sol Insulation products they offer are of the highest standard, providing long-lasting performance and value for money. This extensive selection allows customers to find the perfect insulation solution for their specific requirements, whether they are working on new construction projects or retrofitting existing structures.

Hot Products