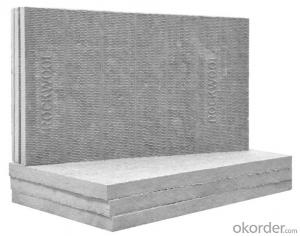

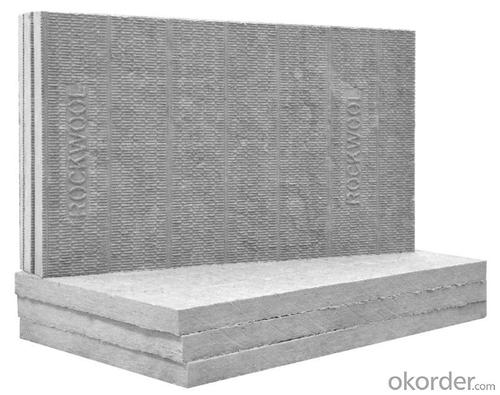

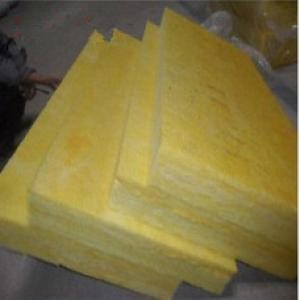

Rock Wool Insulation Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

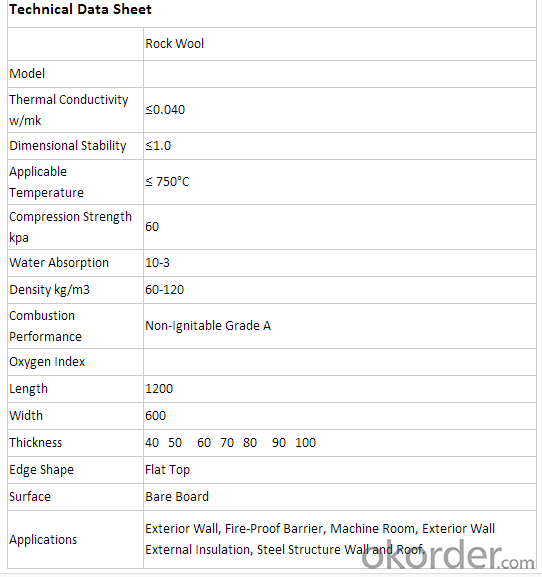

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: Is it dangerous to make mineral cotton mattresses?

- Modern mattresses are generally not a single component, mostly compound.

- Q: What are the differences between slag wool and rock wool?

- People usually referred to as mineral wool rock wool and slag wool, so easy as the two are the same thing, even thought that the slag wool color white, gray green wool is more than "pure", this is a misunderstanding. Although they are all mineral cotton, there are still some differences that can not be ignored. The main reason for these differences is the composition of the ingredients.

- Q: The difference between rock wool and mineral wool

- Cotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.

- Q: Does water paint spray fire in underground space?

- NeededWater based brand fire retardant paint thickness is determined by base material, such as wood, steel structure, etc.:1. ultra thin structure fire retardant coating (0-3mm)2. thin steel structure fire retardant coating (3-7mm), fire-resistant 2-5h3. thick steel structure fire retardant coating (7-45mm), applicable to high-rise civil buildings, columns, general industrial and civil construction, fire up to more than 3H4. mineral cotton fire retardant insulation coating

- Q: What material is fast heated and kept warm?

- The gap between the heating tube and the aluminum tube is filled with a heat conductive insulating elastic rubber, so that the heat can be rapidly transferred to the aluminum tube.Conductive heat insulation elastic rubber adopts silicon rubber base material, boron nitride, alumina and other ceramic particles as filler, the heat conduction effect is very good. Under the same conditions, the thermal impedance is smaller than that of other thermal conductive materials. Having a soft, clean, no pollution, high insulation and radiation characteristics of glass fiber provides good mechanical properties to reinforcement, anti piercing, shear resistance, tear resistance, with conductive pressure-sensitive adhesive.

- Q: Exterior wall insulation putty powder construction needs to pay attention to what problems?

- The production enterprise of rock wool board insulation system should have professional guidance in the construction process, and cooperate with construction units and site supervision to do construction quality control work. Material access must be in accordance with specifications, quantity and quality requirements, after acceptance of qualified to storage, and should be kept by hand, is strictly prohibited open-air stacking. Curtain wall rock wool board should be overhead damp proof piling up. Plastering construction should meet the following requirements: rock wool board paste after surface treatment with plaster surface plate, scraping the mortar on the surface coated with a stainless steel spatula (thickness 1 ~ 1.5mm), and press the rock wool board surface fiber. Mortar should be configured in strict accordance with product instructions, configuration of the adhesive should avoid direct sunlight, and should be used within 2h.

- Q: How can the interior drain be silenced?

- A sewer pipe commonly used rock wool make noise processing (must be closed, it is said that rock wool can be carcinogenic) but in general, even a simple sound will hear the noise, just reduce it, if there is higher demand for insulation,You can also use wooden boards to make boxes, wrap the hose down, fill it with foam, and, with the aid of the ceiling material, reduce noise. Such as: sound-absorbing board, PVC foam board and so on.

- Q: What are the differences and prices between rock wool board and mineral wool board?

- The habit of speaking, usually will use slag as the main raw materials to produce products known as mineral wool, and the use of natural rocks such as basalt or diabase as the main raw material for the production of a product called rock wool;

- Q: What are the exterior wall insulation materials?

- Polystyrene particle insulation slurry; this material has the advantage of better water absorption, the use of this material, we must do a good crack waterproof layer, can prevent cracks.

- Q: Fireproof rock wool board can be used as firewall?

- You need to know what material the firewall is made of What are its standards and requirements? What's the function of it? When you know all about it, you won't take a piece of board to make a wall!

Send your message to us

Rock Wool Insulation Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords