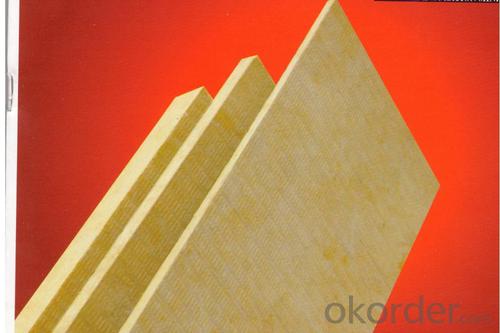

Rock Wool Board for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

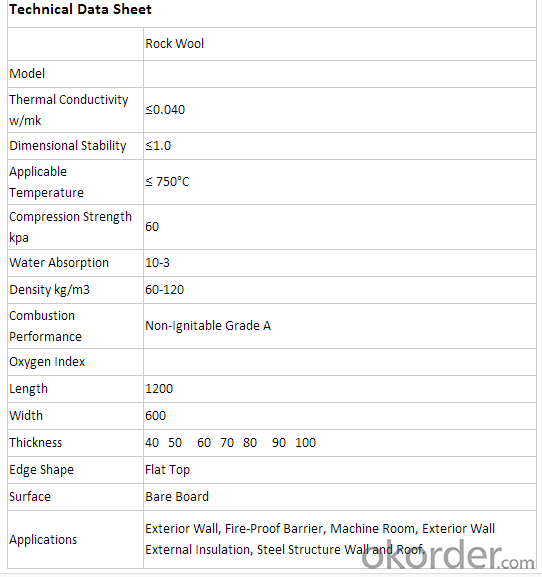

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q: What are the building energy saving materials?

- Rock wool is a selection of basalt or diabase as the main raw material, made by melting high temperature inorganic artificial fiber. Rock wool products have good thermal insulation, heat insulation, sound absorption, heat resistance, non combustion, and good chemical stability. Rock wool used for exterior walls of buildings. There are three forms of insulation: internal heat insulation, central sandwich insulation and external insulation.

- Q: How can the exhaust pipe of a gas water heater be insulated by going through the glass?

- Therefore, the temperature of the inner pipe of the water heater is higher, but the outer pipe is not very high because the outdoor air is flowing.At the same time, the air is a poor heat conductor, so the actual temperature of the outer surface of the outer tube of the water heater is not very high. That is to say, no special heat insulation measures are needed when the exhaust pipe of the gas water heater passes through the glass.

- Q: Advantages of exterior wall energy saving and environmental protection heat insulation coating

- Although the market is rich in exterior wall insulation products, but inorganic thermal insulation materials in addition to A-class fire retardant performance and good insulation effect, but also has excellent insulation system structure without network. In simple construction, and buildings with life, water resistant anti crack and anti hollowing fields occupy an increasingly important position.

- Q: What's the difference between glass fiber and mineral wool?

- Referred to as mineral wool. With non flammable, no mildew, no borers and other properties. Made into felt, blankets, mats, ropes, plates and so on. Used as sound absorption, shock absorption and heat insulation material.

- Q: The difference between rock wool and mineral wool

- By the above two concepts, we should compare the difference between rock wool and slag cotton.1., raw materials are different: to metallurgical slag or fly ash as the main raw material called slag cotton; basalt and other rock as the main raw material called "rock wool"".2. the coefficient of acidity of rock wool and slag cotton is also different. Rock wool acidity coefficient MK generally greater than 1.5, and even up to more than 2; slag cotton MK generally can only be maintained at around 1.2, it is difficult to more than 1.3.3. because of the difference between chemical composition and acidity coefficient of rock wool and slag cotton, they also show some differences in performance.(1) the difference of water resistance(2) difference of heat resistance;(3) difference in corrosion resistance

- Q: Does water paint spray fire in underground space?

- Waterborne paint itself is waterproof, unlike oil paint as security for.

- Q: What are the requirements for floor and exterior wall waterproofing in building construction?

- The joining of different structural materials shall be made of salt resistant fiberglass mesh or hot galvanized galvanized wire mesh of not less than 150mm on each side for anti cracking strengthening treatment

- Q: Why should the insulation board be spliced when it is installed?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

- Q: How can the interior drain be silenced?

- Bathroom noise treatment is the family decoration, is very important and easy to ignore a link. Because of the noise treatment process, unlike waterproofing, fire protection works are essential decoration projects. Ignoring the noise treatment of the household is only affecting the quality of life of the owner.

- Q: What is the heating tube cotton insulation material itch on the body?

- A type of mineral cotton. Short fiber made from blast furnace slag

Send your message to us

Rock Wool Board for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords