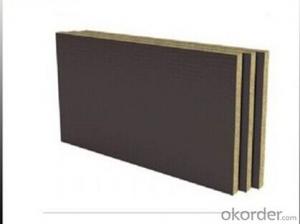

Heating Insulation and Fireproof Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Grade A1 non-combustible

2.Acidity coefficient is above 1.8

3.Thermal conductivity(Room temp.) is less than 0.04w/m.k

Rock wool is made from natural rock such as basalt, diabase and dolomite. The natural rock are melted into melts in cupola at a very high temperature about 1500°C. And the melts lava is then pour to high speed spinners through which the melts get into fibers. At the same time, the phenolic binder containing silicon and mineral oil etc are sprayed onto the surface of each fiber homogeneously. The just fiberized fibers are collected together to form the original wool mat through negative pressure resulted from suction. The original wool mats then pass through pendulum, crimping and pressing process, get into the curing oven through which the wool mats are cured and shape up to different kinds of products such as board, mat and pipe section etc with different usage.

Rock wool products are free of asbestos, and do not apply any composition harmful to environments such as CFCs, HFCs and HCFCs etc, no harm to human health, do not increase the risk of cancerogenesis. After many years research, the World Health Organization agency of Research made a decision to exempt rock wool from the list of "possibly cancer causing agents". This decision supported the fact that rock wool is safe to users or worker occupational exposure to rock wool fibers.

The properties of non-combustibility, high temperature resistance and porous fiber construction of Jesion rock wool products, makes them have very good performance on fire resistance, thermal insulation and acoustic insulation. The rock wool products are widely use for industry field, building and marine & offshore field to increase the energy efficiency, decrease pollution agent discharge, and improve fire safe situation. Meanwhile, some rock wool products can also be used as the planting substrate for many kinds of vegetables, flowers and fruits.

- Q:What are the kinds of fire door core board?

- Organic thermal insulation material, fire door core is such as EPS (foam polystyrene), XPS (extrusion foaming polystyrene), foam PVC, foam PE, foam PUR and sponge rubber as raw materials and other products. But because of flammability and combustion of organic materials to produce VOC, hinder the application of these materials, this also appeared over the pursuit of improve flame retardant properties of organic materials, and enhance the level of fire safety phenomenon, it not only greatly increased the cost of materials, at the same time as the non environmentally friendly flame retardant are on fire the process will increase the amount of smoke and smoke toxic materials, fire may bring greater harm, so the organic material as the core material of the fire door is not desirable.

- Q:What is the best sound proof cotton in the decorative plaster board partition wall? Mineral wool rock and glass wool.

- At present, the market is the best sound effect is said to be gradient sound-absorbing cotton, as well as high barrier sound felt. The price is relatively high, the price range is 55-80 yuan per square meter. The advantages of its products are more environmentally friendly, first of all, the construction will not cause skin itching. No emissions. It won't be pulverized. The sound absorption effect is reflected in the full frequency silencing, and has a good reduction effect on low frequency, intermediate frequency and high frequency sound. High barrier acoustic felt is reflected in its high damping performance. It can effectively restrain the sound propagation caused by resonance when it is attached to the thin plate. Usually relatively high-end, or official sites are more respected.

- Q:What are the requirements for floor and exterior wall waterproofing in building construction?

- Building exterior wall waterproof design should include the structure through windows and doors, awning, balcony, cracks, out wall casing, capping, embedded parts, prefabricated wall parapet and the intersection area of waterproofing. 5.1.3 the waterproof layer of the exterior wall shall be installed on the surface of the water.

- Q:Why should the insulation board be spliced when it is installed?

- The EPS plate shall be bonded in a vertical arrangement and the vertical seam shall be staggered along the line. Insulation board construction fault seam stitching truth with brick walls are brick seam is a reason for strong security.

- Q:What materials should be used for building energy saving? Why?

- Rock wool is a selection of basalt or diabase as the main raw material, made by melting high temperature inorganic artificial fiber. Rock wool products have good thermal insulation, heat insulation, sound absorption, heat resistance, non combustion, and good chemical stability. Rock wool used for exterior walls of buildings. There are three forms of insulation: internal heat insulation, central sandwich insulation and external insulation.

- Q:How about the appearance of glass wool, mineral wool and asbestos?

- Glass wool belongs to a kind of glass fiber, it is a kind of man-made inorganic fiber. Quartz, sand, limestone, dolomite and other natural ore as the main raw materials, with a number of soda ash, borax and other chemical raw materials into glass. In the melting state, by means of external force, the system is thrown into flocculent fibers, and the fibers and fibers are made of solid intersection. They are intertwined with each other and show a lot of small gaps. This gap can be considered as a pore. Therefore, the glass wool can be regarded as a porous material and has good thermal insulation and sound absorption performance.

- Q:Advantages of exterior wall energy saving and environmental protection heat insulation coating

- At present, there are many kinds of exterior wall insulation materials in the market, which can be divided into organic insulation materials and inorganic insulation materials. Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

- Q:What are the properties of fire-resistant coatings for steel structures?

- Thick steel structure fire retardant coating refers to the steel structure fireproof coating with coating thickness greater than 7 mm, less than or equal to 50 mm, granular surface, little density, low thermal conductivity, and refractory limit of 2 h or more. Because of the thick fire retardant coating composition for inorganic materials, so the fire performance is stable, long-term effect is good, but the coating components of larger particles, the coating appearance is not smooth, affect the overall appearance of the building, so most structure for concealed works. In the fire, the material has a granular surface, a smaller density, a low thermal conductivity, or a heat absorbing property in the coating, delaying the temperature rise of the steel and protecting the steel. This kind of fire retardant coating is suitable for inorganic binder (such as water glass, silica sol, aluminum phosphate salt, refractory cement, etc.) together with inorganic light insulation aggregate materials (such as perlite, vermiculite, bouldering, sea and fly ash cenosphere), fire retardant additives, chemicals and materials (enhanced such as rock wool, aluminum silicate fiber, ceramic fiber, glass fiber and filler) mixed together, has the advantages of low cost. Spraying is often used in construction. It is suitable for indoor and outdoor concealed steel structure, high-rise steel structure and multi story steel structure with requirements of fire resistance above 2 h. Such as: high-rise building columns, general industrial and civil buildings in support of multi-storey columns of fire resistance should reach 3 h, the need to use this thick fire-retardant coating protection.

- Q:Fireproof rock wool board can be used as firewall?

- Composite rock wool board and slag wool board referred to as mineral wool, slag wool has been widely used in metallurgy, machinery, building materials, petroleum and chemical industry in 1970s, rock wool used for external wall thermal insulation in developed countries such as the EU has a history of nearly 30 years, but in our country because of its high cost and production cost, the economic costs of organic insulation the material is greater than, the application range is not big.

- Q:What are the building energy saving materials?

- At present, China's common energy-saving insulation materials are mainly rock wool, glass wool, polystyrene foam, cement, polystyrene board, silicate composite insulation mortar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heating Insulation and Fireproof Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords