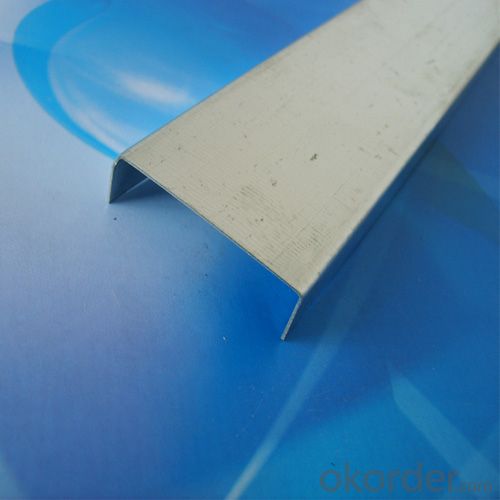

Used For Drywall/ Ceiling Designs/ Metal Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantages and features:

1. Our products’ raw material is high quality hot dipped zinc galvanized steel strip, absolute fireproof and heat insulation, waterproof and antirust, anticorrosive , high durability

2.Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3. Double sized galvanization volume make sure that the plaster bone is corrupt and rust resistance.

4. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

5.manufacture the special specification products for customers

6. High quality raw material guarantees the light steel keel of life and good performance of construction.

7. Possese own ten precision cold rolled steel strip production line.

Certificates

ISO 9001:2000 Quality management system.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- The general keel material costs 34 or so manual 15 that you look at the offer

- Q: Light steel keel wall how to install glass door

- And the normal installation of the same glass doors, but to consider the load-bearing, door frame to be reinforced, upstairs that useful wood panels are also available. However, we usually use the side tube to do support.

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q: Gypsum board partition wall how to sound insulation

- Brush the EL1230 interface agent with hungry wolf adhesive paste Yanmian insulation board, and then apply anti-cracking mortar protective layer.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, the gypsum board partition wall is not much weight, far less than the prefabricated board capacity

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- Keel fixation requires the use of expansion bolts fixed, but now many practices are directly linked with steel nails, so more convenient, the effect is almost, of course, is not good with expansion bolts. Top and bottom with 75 days keel. Then there are 75 vertical keels.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: Light steel keel partition wall how to paint

- Partition wall painting method: 1, knock on the wall, listen to the sound to find the vertical keel (light steel vertical keel has 5cm width), and then thinner steel needle piercing, to confirm the location of the vertical bone. Select the length of 25mm or more dry wall nail into the load the weight of the whole painting, and then fixed on both sides of the gypsum board position on the balance of the line; 2, before doing the partition, you can consider in the predetermined location plus fine woodworking backplane for later use.

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board wall, refers to the surface with gypsum board to do the closed wall, it is also a "light partition" of a. Lightweight partition, which includes gypsum board partition, cement board partition, light block brick wall and so on.

Send your message to us

Used For Drywall/ Ceiling Designs/ Metal Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords