Metal Studs, Ceiling Drywall Metal Stud.

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

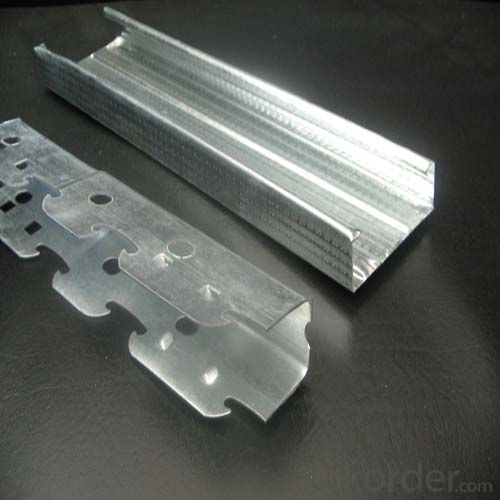

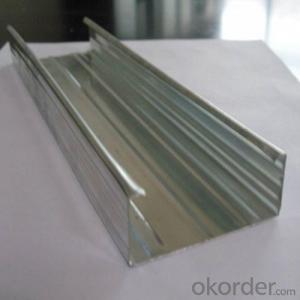

C channel metal stud sizes/decorative metal studs/drywall metal stud sizes

Features:

(1)Lightweight to carry and handle.

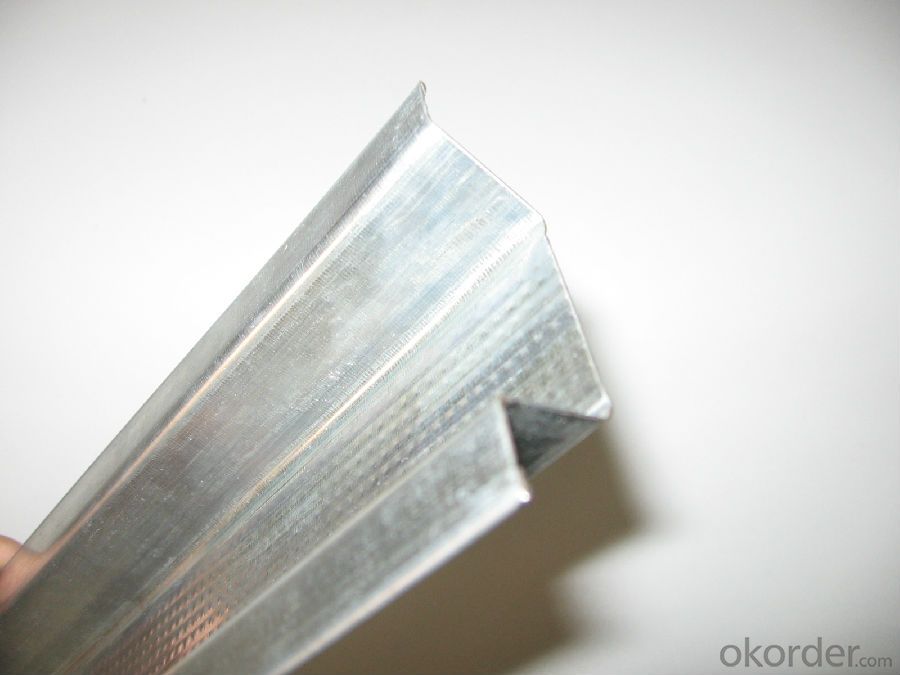

(2)High-quality steel: its surface is smoothness and it hard to distortion.

(3)Rust- proof and Corrosion- resistant: High Zinc Coating of 100 g/m2.

(4)New-type earth-friendly products: galvanized steel-no radiation, not

hazardous material, not pollute the environment.

Ceiling Channel for ceiling system

1. Supporting channel: 38 x 12mm, 30 x 27mm, 50 x 12mm, 50 x 15mm, 60X27mm

2. Covering channel: 50 x 19mm, 60x 27mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Supporting channel: 0. 5mm, 0. 6mm, 0. 8mm, 1. 0mm, 1. 2mm

5. Covering channel: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

6. Wall angle: 25 x 25 x 0. 4mm / 0. 5mm / 0. 6mm

Packing: 10pcs in bundle

3.Image

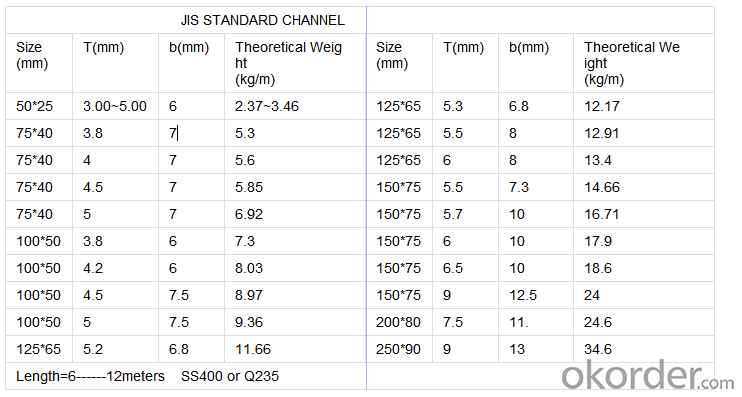

4.Detailed Specification

5.FAQ

Stud and track for partition wall

1. Stud size: 50 x 45mm, 50 x 40mm, 50 x 35mm, 75 x 25mm, 75 x 35mm, 75 x 45mm, 100 x 45mm

2. Track size: 50 x 40mm, 50 x 35mm, 75 x 30mm, 75 x 40mm, 100 x 40mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Thickness: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

The light steel keel material has very well mechanical property, high precision on size, well linearity, flat panel. It is ametabolic and it can avoid cranny causing by ceiling installation.

Fixity is very good during installation, with unique pocked technique. It is good for avoiding selftapping screw sidesliping. It not only improve the speed of construction, but also assure the locked-in connection among materials.

- Q: I was not a tool in the category, or else I got myself!

- Look at the size of the area. Small words are generally not the unit price of the normal words is to use a gypsum board with a gypsum board is 65 - 75 range.

- Q: Shanghai light steel keel ceiling, wall quotes

- Not material money, the wall is generally single to 12 to 18 yuan per square meter, double 18 to 24 yuan per square meter. Ceiling 20 yuan per square meter

- Q: Light steel keel gypsum board wall height is how to determine

- According to the British standard BS5234, different use of the partition wall has different stiffness requirements, the maximum height of the partition wall to determine the criteria for a certain surface load W conditions, the wall of the maximum deflection y does not exceed L / 240; The maximum deformation can not be greater than the L / 240 well system under the 200Pa uniform load. The wind load is superimposed and the uniform load will become larger

- Q: Is it good for brick walls or light walls?

- Each have their own benefits ah Brick wall is more sound and more solid friends Light wall, then light, do not take up a lot of space to remove or remove

- Q: How to remove the gypsum board cut off

- To deal with the local property, to understand the removal of the area to be noted, such as the demolition of the mall will be sealed room, so that the impact of dust and garbage next door store business. And the parties to deal with more, will facilitate the back of the work.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Must want to do it. Recommended use of lacquered glass (keel must use heavy-duty installation of reliable), or white glass selection of aluminum keel. More reliable.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- Gypsum board at the end of the seams should be open groove, easy to capping processing. Gypsum board edge joints should be in accordance with the provisions of the process.

- Q: Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- First do a good wall partition 2.8 high, 6 meters high in the top if it is the roof, then use the boom directly pull down

Send your message to us

Metal Studs, Ceiling Drywall Metal Stud.

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords