Galvanized Steel Metal Stud and Tracks for Drywall and Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

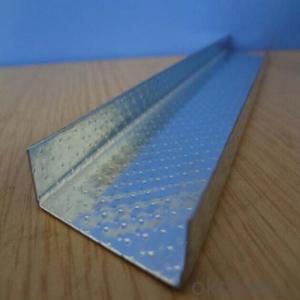

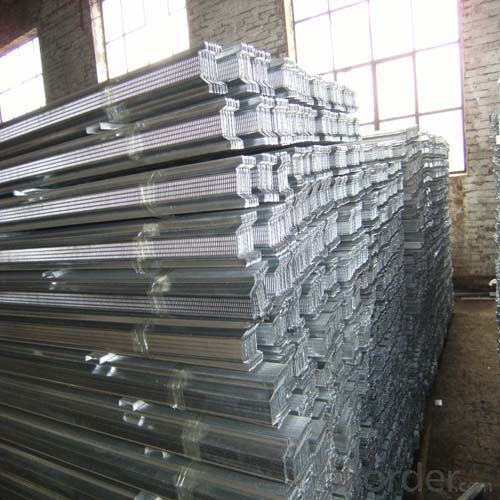

Galvanized Steel Metal Stud and Tracks for Drywall and Ceiling

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Detail description

Drywall 35*22*12*68, thickness 0.45mm - 1.0mm,length 2.8mm,2.9mm,3mm

Drywall

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Advantages of Galvanized track and stud

1 Save the cost:

The material of the track and stud we can offer it by ourselves.

2 Quality assurance:

Our products raw material is high quality hot dipped zinc galvanized steel strip, absolute fireproof and heat insulation, waterproof and antirust, anticorrosive , high durability.

3 Rich experience:

Selling well in Middle East , Africa ,Australia, Malaysia ,and America , where the products have enjoyed an excellent reputation with high quality and services

4 Technical support:

Except the conventional product we can professionally manufacture the special specification products for customers.

Advanced equipment and technology can make sure the products exactly size, high quality

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: I was not a tool in the category, or else I got myself!

- Look at the size of the area. Small words are generally not the unit price of the normal words is to use a gypsum board with a gypsum board is 65 - 75 range.

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- With the filling block wall, and the same brick with the nail what is no problem, the weight is not heavy, the thinnest filling block is 120 thick, even the total thickness of double-sided plaster does not exceed 180, or light The partition wall is also the line, faster, but also durable, more than gypsum board wall to spend more, but at least the first nibbling nails are no problem, more durable and reliable, the weight is also light, the normal stay on the trip.

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Light steel keel wall can be installed sliding door

- Can press, but the wall material is not good, no, can pull the wall bad

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- 1 enhances the integrity, stability and shock resistance of the partition The construction of the law in the ridge before the construction of the ground keel fixed screw and attached to the wall of the fixed support frame in place in the concrete floor, and with the wall to the ridge poured into one, changing the structure of the connection, enhanced Wall integrity, stability and shock resistance. 2 effective prevention of keel deformation and wall panel cracking and other quality problems This method can increase the rigidity of the keel on both sides of the door and the wall pendulum by increasing the steel way to prevent the deformation of the keel system due to the external force. The installation of the fixed and cantilevered structure of the steel member wall, The ridge production, are completed once, changed the wall after the completion of the installation of the toilet or wall equipment, the construction of the cantilevered structure of the platform, effectively control the wall panel cracks and other quality problems. 3 sound insulation and fire effects Embedded in the ridge of the fixed support steel components of the dislocation of the installation, in the world keel and roof and ridge between the border keel and structural walls paved between the fire noise cotton, and sealed with fire sealant, and 100 ㎜ thick gypsum board partition system sound insulation performance equivalent to the traditional 240 mm brick wall effect, reduce the amplitude, enhance the light steel keel wall insulation and fire effects.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- The walls of the bathroom must be waterproof and moistureproof, or it will be deformed and affect life. And the bathroom wall to do the waterproof treatment, or the toilet to the area of water and more will then penetrate the other side of the wall.

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q: Light steel keel wall cheap or cheap red brick

- Now steel is more expensive! Red brick a 4 corner 2 points! It's cheaper to look at yourself!

- Q: Light steel keel partitions and finished partitions

- Light steel keel partition is one of the most common decoration projects in the field of decoration and decoration. It is made of light steel keel as the basic skeleton, the surface gypsum board is made of wall layer and fixed to the top and top of the building. Wall; it needs to use talcum powder, such as putty layer, latex paint or wallpaper as a surface decoration, are produced on-site.

Send your message to us

Galvanized Steel Metal Stud and Tracks for Drywall and Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords