QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Scaffolding For High-Rise Buildings Formwork Scaffolding Truss High Quality

Frame Scaffolding Systems Formwork Bs Standard Scaffolding Tube With Low Price

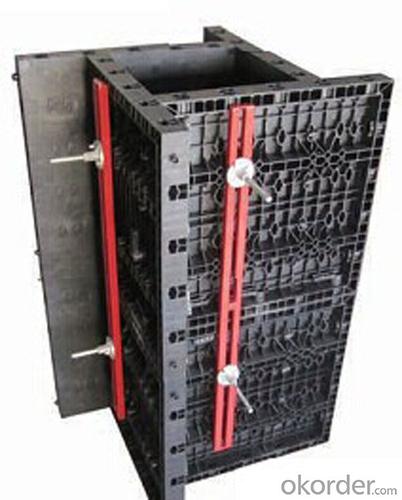

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: How is steel frame formwork dismantled after concrete curing?

- Steel frame formwork is typically dismantled after concrete curing by removing the formwork panels and props. The panels are carefully unclamped and lifted away from the concrete structure using cranes or other lifting equipment. The supporting props are then removed, ensuring the structure's stability is maintained throughout the process. This dismantling method allows for the easy and efficient removal of the steel frame formwork, leaving behind a solid and robust concrete structure.

- Q: Can steel frame formwork be used for both horizontal and vertical reinforcement?

- No, steel frame formwork cannot be used for both horizontal and vertical reinforcement. Steel frame formwork is primarily used for vertical reinforcement, such as columns and walls, as it provides strong support and stability during the pouring and curing process of concrete. However, for horizontal reinforcement, such as beams and slabs, other formwork systems like timber or aluminum are commonly used. These formwork systems offer greater flexibility and ease of installation for horizontal reinforcement, which typically requires more intricate designs and arrangements.

- Q: Does steel frame formwork require any specific joint sealing measures?

- Yes, steel frame formwork does require specific joint sealing measures. Joint sealing is necessary to ensure that the concrete being poured into the formwork does not leak or spill out through the joints. This can lead to poor concrete quality and compromised structural integrity. To prevent such issues, various joint sealing measures can be taken. One common method is to use joint sealing tapes or strips made of elastic materials, such as rubber or silicone, which are placed along the joints to prevent leakage. These tapes or strips are typically applied to both the inner and outer sides of the formwork joints. In addition to tapes, sealant compounds can also be used to fill any gaps or voids in the joints. These sealants are typically applied after the formwork is assembled and before the concrete is poured. They provide an additional layer of protection against leakage. It is important to ensure that the joint sealing measures are properly installed and maintained to prevent any potential issues during the concrete pouring process. Regular inspections should be conducted to identify any damage or wear to the joint sealing materials, and they should be repaired or replaced as necessary. Overall, joint sealing measures are crucial for steel frame formwork to ensure the successful containment of the concrete and to achieve the desired structural strength and durability.

- Q: What are the different types of formwork bracing used with steel frame formwork?

- Steel frame formwork can be supported and stabilized by various types of formwork bracing. These bracing systems serve to provide the necessary support and stability during the pouring of concrete. 1. Vertical bracing can be achieved using adjustable steel props. These props are vertical elements composed of a steel tube with a threaded end and a base plate. Their height can be adjusted, and they are secured in place using locking pins. 2. Lateral stability is ensured through the use of horizontal steel bracing. This form of bracing involves steel tubes connected to the vertical props and fastened with clamps or couplers. Regular intervals along the formwork's length are fitted with this bracing. 3. Diagonal bracing provides diagonal support to the formwork. Steel tubes are connected to the vertical props and secured using clamps or couplers. Varying angles are implemented to maximize stability. 4. Additional strength and stability are achieved by employing tie rods. These rods feature threaded ends and connect the formwork panels together. Nuts and washers are used to tighten the tie rods and hold the formwork in place. 5. Cross bracing is utilized to enhance lateral stability. Steel tubes are diagonally connected between the vertical props. Regular intervals are fitted with cross bracing, preventing any formwork shifting or movement. In summary, these various types of formwork bracing used with steel frame formwork are designed to ensure support, stability, and strength throughout the concrete pouring process. These bracing systems are essential in maintaining the formwork's position and withstanding the pressure exerted by the concrete.

- Q: Can steel frame formwork be used for both low-rise and high-rise buildings?

- Steel frame formwork is suitable for both low-rise and high-rise buildings. This versatile and durable system can withstand the weight and pressure of concrete during construction. It is easy to assemble and disassemble, making it adaptable to different building heights. Furthermore, the steel frame formwork can be customized to meet various floor layouts and structural needs. Its strength and stability make it an excellent option for both low-rise and high-rise construction projects.

- Q: What are the load-bearing capacities of steel frame formwork panels?

- The load-bearing capacities of steel frame formwork panels can vary depending on their size, design, and specific application. However, these panels are generally designed to withstand significant loads, often ranging from several hundred to several thousand pounds per square foot. It is important to consult the manufacturer's specifications and engineering guidelines for accurate load-bearing capacity information for a specific steel frame formwork panel.

- Q: Can steel frame formwork be used for both residential and industrial flooring?

- Yes, steel frame formwork can be used for both residential and industrial flooring. Its strength and durability make it suitable for various construction applications, providing stability and support for concrete pouring and ensuring a solid foundation for both residential and industrial flooring.

- Q: Are there any restrictions on the concrete mix design that can be used with steel frame formwork?

- Yes, there are some restrictions on the concrete mix design that can be used with steel frame formwork. Steel frame formwork is a type of formwork system that is designed to support the weight of the concrete during pouring and curing. It consists of steel frames that are assembled to create a mold for the concrete. One of the main restrictions is related to the workability of the concrete mix. The concrete mix used with steel frame formwork should have a certain level of workability to ensure that it can be easily poured into the formwork and properly compacted. If the concrete mix is too stiff or too fluid, it can lead to issues such as poor compaction, segregation, or excessive bleeding. These issues can compromise the quality and strength of the final concrete structure. Another restriction is the strength of the concrete mix. The concrete used with steel frame formwork should have sufficient strength to support the weight of the formwork and the concrete itself without any deformation or failure. The strength of the concrete is determined by the mix design, which includes the proportions of cement, aggregates, water, and any admixtures. The mix design should be carefully selected to achieve the desired strength and durability of the concrete. It is also important to consider the curing requirements of the concrete mix. After pouring, the concrete needs to be properly cured to achieve its full strength and durability. Steel frame formwork can affect the curing process by providing some level of insulation, which can influence the rate of hydration and the development of strength in the concrete. Therefore, the concrete mix should be designed to account for the curing conditions associated with steel frame formwork. In addition, certain admixtures or additives may not be compatible with steel frame formwork. For example, some admixtures that accelerate or retard the setting time of the concrete may interfere with the proper installation and removal of the formwork. It is important to consider the compatibility of admixtures with steel frame formwork and consult with experts or manufacturers to ensure that the concrete mix is suitable for use with this type of formwork. Overall, while there are restrictions on the concrete mix design that can be used with steel frame formwork, it is possible to design a mix that meets these requirements. It is important to carefully consider factors such as workability, strength, curing requirements, and compatibility with admixtures to ensure the successful and efficient use of steel frame formwork in concrete construction projects.

- Q: Can steel frame formwork be used for the construction of power plants?

- Yes, steel frame formwork can be used for the construction of power plants. Steel frame formwork provides a strong and durable support system for the concrete structures required in power plant construction. It offers the necessary stability and flexibility to accommodate the complex designs and specifications of power plant structures, making it a suitable choice for such projects.

- Q: What are the disadvantages of using steel frame formwork?

- Using steel frame formwork in construction projects has a few drawbacks. Firstly, the initial cost is higher compared to other options like wood or aluminum. This can increase the overall project cost, especially when working on a tight budget. Secondly, steel formwork can be heavy and challenging to handle. Unlike lighter materials, it requires specialized equipment and skilled labor to transport and assemble on site. This adds to the construction timeline and labor costs. Another disadvantage is the limited flexibility of steel formwork. Once the frames are built, making changes or adjustments can be difficult. This becomes problematic if design modifications or unforeseen circumstances arise, as dismantling and reassembling the formwork takes significant time and effort. Additionally, steel formwork is susceptible to corrosion and rusting if not properly treated or maintained. Exposure to moisture or harsh weather conditions can deteriorate the frames over time, compromising the structural integrity. Regular inspections and maintenance are necessary to prevent corrosion and ensure longevity. Lastly, steel formwork may not be suitable for every construction project. Its weight and rigidity may not be ideal for situations with limited access or complex formwork designs. In such cases, alternative systems offering more flexibility may be more appropriate. Overall, while steel frame formwork has advantages in strength and durability, it is important to consider the potential disadvantages such as high cost, difficulty in handling, limited flexibility, susceptibility to corrosion, and suitability for specific project requirements.

Send your message to us

QES Scaffolding Formwork Scaffolding Wall Tie with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords