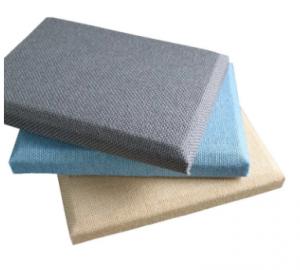

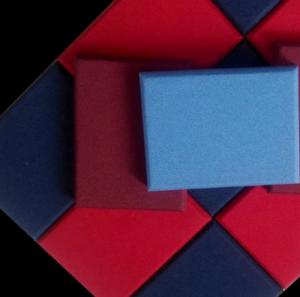

Fiberglass Acoustc Wall Panels for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass acoustic wall panel is made from high density fiberglass wool as the base material, with fabrics on the surface; four edges are securely glued. Suitable for the indoor wall panels of public place, such as the meeting room, school, studio room, cinema and theatre etc, effectively reduce the noise level. It is an excellent sound absorption product.

Specifications:

Density: 100kgs/m3, 120kgs/m3

Thickness: 25mm, 30mm, 40mm, 50mm, 75mm

Size: 600*1200mm, 1200*1200mm, 600*1800mm, 600*2400mm and etc.

Surface: Different kinds and colors of fabrics

Edge: Square, Bevel

Technical Data:

Fire proof: Base board Class A incombustibility, surface fabrics incombustibility can be customized.

Thermal Insulation: ≥0.5 (m2·k/w)

Damp-proof: Max 90% R/H at 40℃

Moisture content: ≤1% (JC/T670-2005)

Environment friendly: Product and package can be recycled.

Clean: wipe with soft fabric

Features:

1. Excellent performance of sound absorption, effectively reduce noise levels.

2. Various decorative fabric and colors can be applied, produces an effect of luxury and elegant.

3. Stable dimension under the high temperature and humidity.

4. Good thermal insulation performance, energy saving.

5. Easy installation and adjustment.

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q: How to do with glass fiber wall anti-crack

- Do not have to be fainted by the glass fiber, although the use of glass fiber, the surface can not see the crack, but in fact still strong, no use, their own fool themselves; recommended landlord with anti-cracking latex paint, such as Mo Wei Latex paint, it can be painted when the wall can make up for the small cracks in the wall, and the film after forming a certain degree of flexibility to prevent the emergence of cracks, this effect is only Mo Weier can do, please landlord reference!

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If the walls of the cracks are more words, you can use the grid covered with paste, and then batch of putty construction;

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is grc widget

- Grc components, also known as grc, is a glass fiber reinforced cement composite material, the middle is empty, made by the two pieces of stitching, the components themselves have glass fiber, the characteristics of cement alkali resistance, divided into many kinds, There are grc relief, Guangyou grc lines, grc Roman column, grc window sets and so on.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The composite material is mainly composed of two parts: the reinforcing material and the base material: Reinforcing material: does not constitute a continuous phase in the composite material to the main mechanical properties of composite materials, such as fiberglass in the glass fiber, CFRP (carbon fiber reinforced plastic) in the carbon fiber is reinforced. A resin in a single material, such as glass fiber reinforced plastic (GRP), which constitutes a continuous phase of a composite material, is a matrix. Y

- Q: Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

Send your message to us

Fiberglass Acoustc Wall Panels for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords