Acoustic Fiberglass Wall Panel for Cinema

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

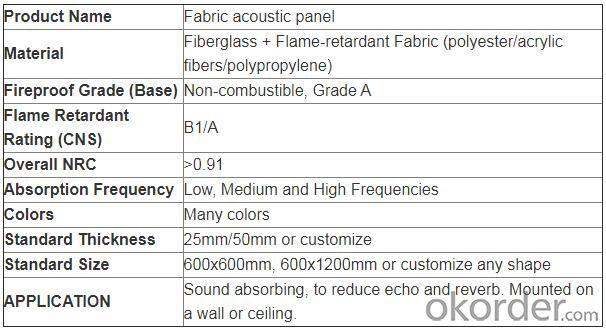

Specification

Description

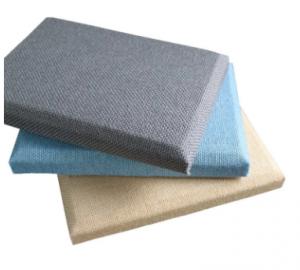

Fiberglass Acoustic Wall Panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: How to do with glass fiber wall anti-crack

- For glass fiber is also used to see you are used in the external walls or interior walls, wall materials are different, a lot of things are not applicable once. Do not apply their own norms. And a slap to shoot the whole law

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- In any case, when the batch wall putty, is not the use of steel wire mesh, and if it is leveling with cement mortar, then you should use the wire mesh.

- Q: FRP can be used to make walls

- Glass (FRP), also known as GRP, that is, fiber reinforced plastic, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastic with fiberglass or its products as reinforcing material, called fiberglass reinforced plastic, or titled fiberglass. As a result of the use of different varieties of resin, so there are polyester glass fiber reinforced plastic, epoxy glass fiber reinforced plastic, phenolic glass steel said. Light and hard, non-conductive, high mechanical strength, less recycling, corrosion resistance. Can replace the steel manufacturing machine parts and cars, ship shell and so on.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- Light wall is a new type of energy-saving wall information, it is a kind of appearance like a hollow floor of the same wall material, but it has two male and female Falcon trough, the device only need to stand up, On a small number of mortar mortar after the assembly can be. It is composed of harmless phosphogypsum, light steel slag, fly ash and other industrial waste residue, by the frequency of steam pressure maintenance. Light wall panels with light weight, high strength, multiple environmental protection, thermal insulation, noise, breathing humidity, fire, rapid construction, down the cost of the wall and other advantages. The inner wall is equipped with reasonable layout of the insulation, sound absorption of inorganic foam profiles or other insulation materials, wall panels by the pipeline pouring, leveling, scientific maintenance, production of high degree of automation, the standard type.

- Q: What is grc widget

- GRC (Glass-fiber Reinforced Cement) glass fiber reinforced cement composite material abbreviation, from the European and American technology, is to alkali-resistant glass fiber, cement, sand and other composite materials according to a certain ratio of mixing, in the mold watering molding, production Modeling rich, texture and diverse products, are widely used in domestic and international characteristics of the building.

- Q: The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- With my experience I think FRP is better, long life, polyurethane foam and FRP is better, the price comparison is not clear, I only know that FRP: give you a unit price of 1.2 thick, 26 per square, 1.5 Thick ,,, 30 per square ;; Polyurethane foam unit price; 900 per cubic.

- Q: Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

Send your message to us

Acoustic Fiberglass Wall Panel for Cinema

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches