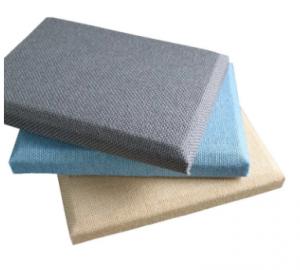

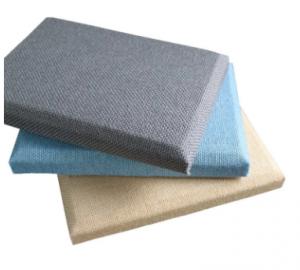

Fiberglass Wall Panels for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass acoustic wall panel is made from high density fiberglass wool as the base material, with fabrics on the surface; four edges are securely glued. Suitable for the indoor wall panels of public place, such as the meeting room, school, studio room, cinema and theatre etc, effectively reduce the noise level. It is an excellent sound absorption product.

Specifications:

Density: 100kgs/m3, 120kgs/m3

Thickness: 25mm, 30mm, 40mm, 50mm, 75mm

Size: 600*1200mm, 1200*1200mm, 600*1800mm, 600*2400mm and etc.

Surface: Different kinds and colors of fabrics

Edge: Square, Bevel

Technical Data:

Fire proof: Base board Class A incombustibility, surface fabrics incombustibility can be customized.

Thermal Insulation: ≥0.5 (m2·k/w)

Damp-proof: Max 90% R/H at 40℃

Moisture content: ≤1% (JC/T670-2005)

Environment friendly: Product and package can be recycled.

Clean: wipe with soft fabric

Features:

1. Excellent performance of sound absorption, effectively reduce noise levels.

2. Various decorative fabric and colors can be applied, produces an effect of luxury and elegant.

3. Stable dimension under the high temperature and humidity.

4. Good thermal insulation performance, energy saving.

5. Easy installation and adjustment.

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q: How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is GRC and can I paint it?

- GRC is the abbreviation of Glass Fiber Reinforced Cement, which is a new type of composite material invented in the 1970s. It is made of alkali-resistant glass fiber as reinforcing material, sulphoaluminate low basicity cement as cemented material and mixed with suitable aggregate Substrate, by jetting. Mold casting. Squeeze out. Flow pulp and other processes made of new inorganic composite materials. The It combines light, high strength, high toughness and water resistance, non-combustion, sound insulation, heat insulation, corrosion resistance, easy processing and other characteristics set in one, occupies a unique position in the building. In recent years, China's GRC technology to a new stage of development. The GRC technology can produce Roman column, eaves line, waist line, door cover, window cover, top set, window side column, light partition board, transformer Such as flue, railing, garden relief, Tibetan components, antique components, mountain flowers, corridor, cultural stone and other hundreds of varieties, smooth and exquisite appearance of the components, pattern smooth realistic, stereotypes perfect, strong sense of art. The following are the same as the " 2, construction, easy installation, short duration. Production of various GRC prefabricated components, with cement affinity. Nine blogs J o? ~?] 5Z?]?]? L 3, GRC components light weight, high strength, good toughness, no cracking, no layer, water, non-combustible, and housing with the life. Spray on the paint, with the stone fought. 4, no "waste" pollution, is conducive to environmental protection. 5, loss. If there is a small amount of damage in the transport can also be installed after the completion of the decoration with cement, to ensure that the utilization of components 100%.

- Q: Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q: The difference between GRC lightweight partition board and ceramic plate

- Hello, the difference between the two is great GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, , Non-combustible, sound insulation, can be sawed, drillable, can be nailed, can be shaved, can chisel, wall smooth construction Jane. Grc components are generally used in high-end villa exterior decoration or European-style building on the external walls of decoration. If the grc component of the type of large number of large Friends of the grc can be opened in the project next to a temporary plant to facilitate the construction of the late, grc components can be divided into color and gray.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- With my experience I think FRP is better, long life, polyurethane foam and FRP is better, the price comparison is not clear, I only know that FRP: give you a unit price of 1.2 thick, 26 per square, 1.5 Thick ,,, 30 per square ;; Polyurethane foam unit price; 900 per cubic.

- Q: Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

Send your message to us

Fiberglass Wall Panels for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords