Fiberglass Decorative Wall Panel Sound Insulation Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

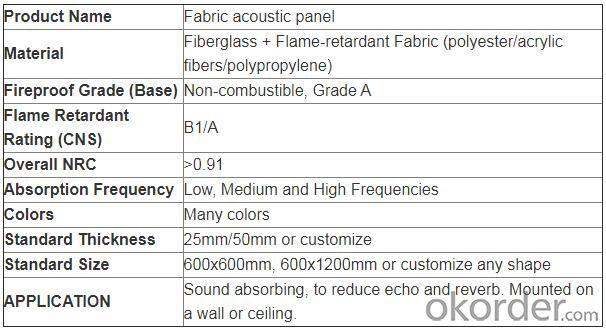

Specification

Description

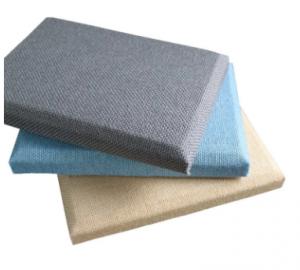

Fiberglass acoustic panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: How to do with glass fiber wall anti-crack

- Do not have to be fainted by the glass fiber, although the use of glass fiber, the surface can not see the crack, but in fact still strong, no use, their own fool themselves; recommended landlord with anti-cracking latex paint, such as Mo Wei Latex paint, it can be painted when the wall can make up for the small cracks in the wall, and the film after forming a certain degree of flexibility to prevent the emergence of cracks, this effect is only Mo Weier can do, please landlord reference!

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced concrete slabs and lightweight aggregate concrete partitions are lightweight wall panels that can be used to make walls. Should be selected materials and processing methods are not the same

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is GRC and can I paint it?

- GRC is also called grc components, refers to the fiberglass made of component-type material, grc shape is based on the external wall of the cad drawings to design, generally do not recommend making paint, grc's exterior decoration has its own treatment.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Wall material that kind of environmental protection?

- Diatom mud soft bag wallpaper floor wall is now a lot of latex paint is also very environmentally friendly

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production process of glass fiber generally includes: raw material procurement, according to the formula for mixing, and then transported to the glass furnace for melting, clarification, through the operating channel flow to the drawing board, sizing agent after drawing through the drawing machine to form the original wire (Usually with yarn, weaving, chopping, puffing, twisting, etc.) or for sale (direct yarn)

Send your message to us

Fiberglass Decorative Wall Panel Sound Insulation Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords