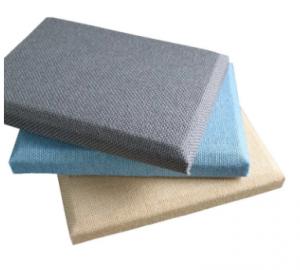

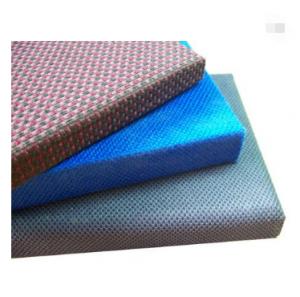

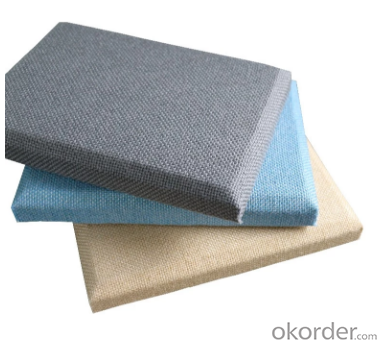

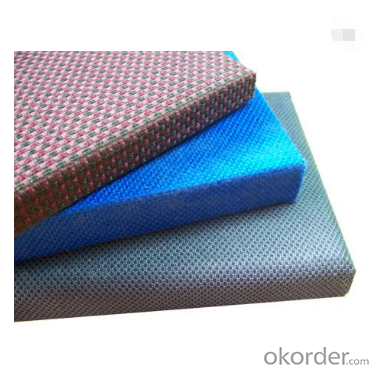

Fiberglass acoustic wall panel with fabric Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass acoustic wall panel with fabric Facing

Specification:

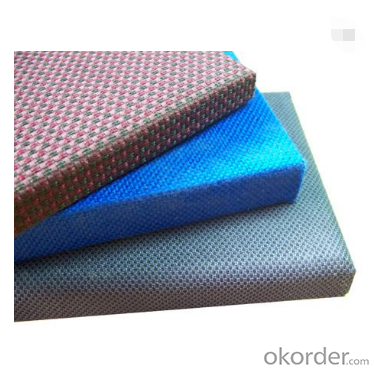

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

Material: Torrefaction compounded high density fiberglass wool

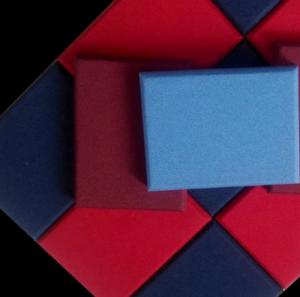

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Fiberglass acoustic wall panel with fabric Facing

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

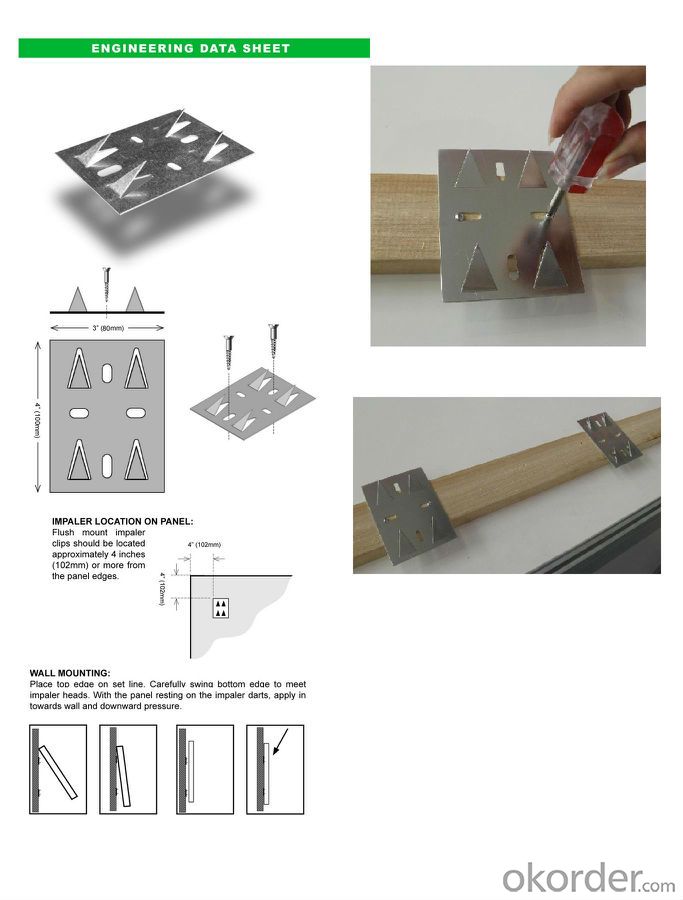

How to install:

Fiberglass acoustic wall panel with fabric Facing

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- In any case, when the batch wall putty, is not the use of steel wire mesh, and if it is leveling with cement mortar, then you should use the wire mesh.

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- Light wall is a new type of energy-saving wall information, it is a kind of appearance like a hollow floor of the same wall material, but it has two male and female Falcon trough, the device only need to stand up, On a small number of mortar mortar after the assembly can be. It is composed of harmless phosphogypsum, light steel slag, fly ash and other industrial waste residue, by the frequency of steam pressure maintenance. Light wall panels with light weight, high strength, multiple environmental protection, thermal insulation, noise, breathing humidity, fire, rapid construction, down the cost of the wall and other advantages. The inner wall is equipped with reasonable layout of the insulation, sound absorption of inorganic foam profiles or other insulation materials, wall panels by the pipeline pouring, leveling, scientific maintenance, production of high degree of automation, the standard type.

- Q: What is grc widget

- GRC (Glass-fiber Reinforced Cement) glass fiber reinforced cement composite material abbreviation, from the European and American technology, is to alkali-resistant glass fiber, cement, sand and other composite materials according to a certain ratio of mixing, in the mold watering molding, production Modeling rich, texture and diverse products, are widely used in domestic and international characteristics of the building.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: The difference between GRC lightweight partition board and ceramic plate

- Hello, the difference between the two is great GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, , Non-combustible, sound insulation, can be sawed, drillable, can be nailed, can be shaved, can chisel, wall smooth construction Jane. Grc components are generally used in high-end villa exterior decoration or European-style building on the external walls of decoration. If the grc component of the type of large number of large Friends of the grc can be opened in the project next to a temporary plant to facilitate the construction of the late, grc components can be divided into color and gray.

Send your message to us

Fiberglass acoustic wall panel with fabric Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches