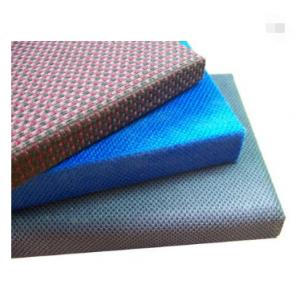

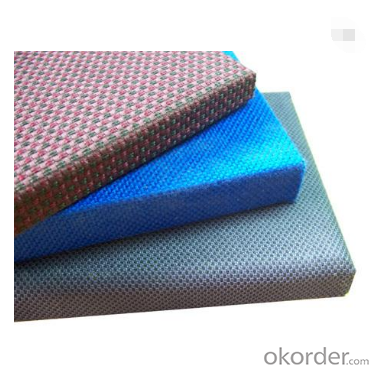

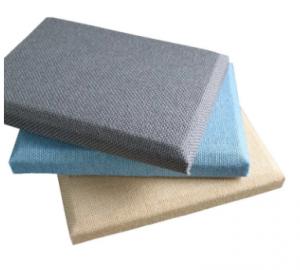

Fabric wrapped fiberglass acoustic wall panel CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fabric wrapped fiberglass acoustic wall panel CNBM

Specification:

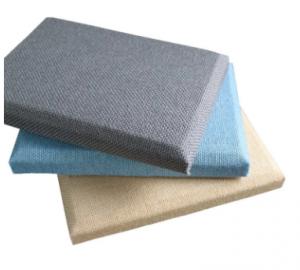

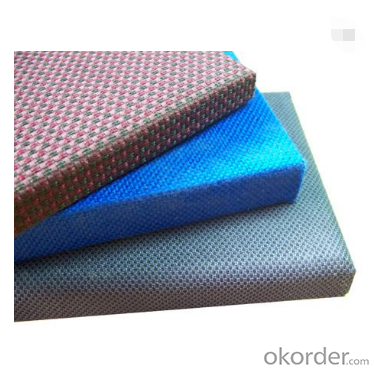

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

Material: Torrefaction compounded high density fiberglass wool

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Fabric wrapped fiberglass acoustic wall panel CNBM

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

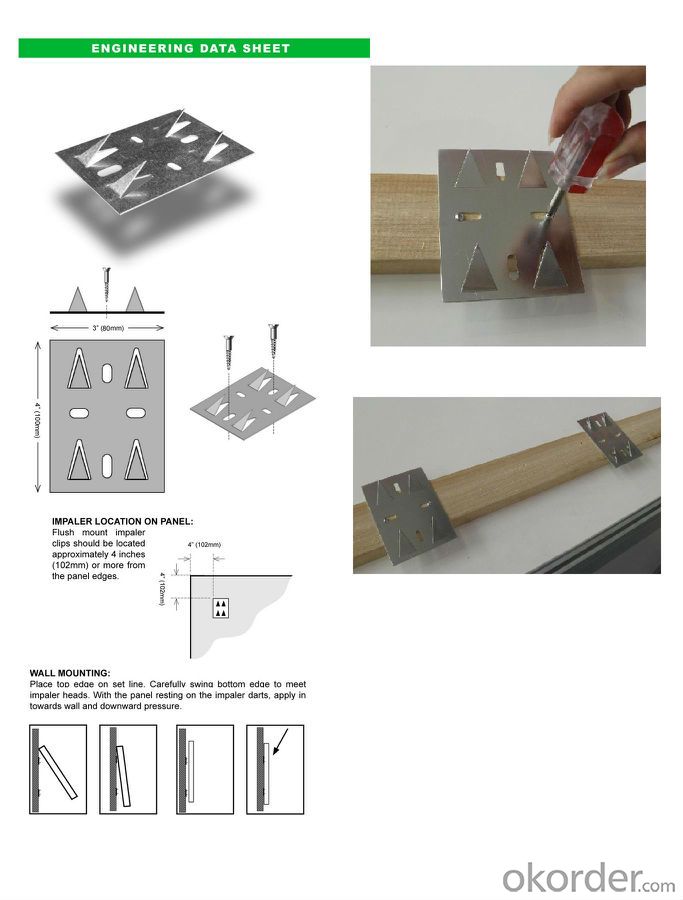

How to install:

Fabric wrapped fiberglass acoustic wall panel CNBM

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: What is the quality of the light barrier now?

- . Increased use of building area: the wall can increase the use of an area of 8-10% or more, is the property development buyers and sellers are happy to accept.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- Lightweight aggregate concrete partition board: is made of lightweight aggregate concrete slab, which is suitable for ordinary building grade. Lightweight aggregate concrete is made of natural light aggregate (such as pumice) or artificial light aggregate (such as ceramic) or industrial waste light aggregate (such as slag beads) plus cement and water mixed with concrete. Lightweight aggregate concrete and ordinary concrete is the difference between light aggregate concrete without stones, and some of his aggregate can float on the water.

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What should the overall wardrobe design should have?

- The main features of the overall wardrobe are: standardized modules, tailor-made. The overall wardrobe according to the different styles can be divided into integral, into the wall, support and into the four categories. The overall design of the wardrobe and the pursuit of harmony with the home, in a warm atmosphere of life, bringing a simple and stylish charm, so that you poetic dwelling, artistic life. Therefore, the overall wardrobe style selection and design is essential:

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The partition board refers to the wall prefabricated slabs for the interior wall of the JG / T169-2005 "Building slabs for use with partitions". The partition panels contain glass fiber reinforced cement slabs, glass fiber reinforced Gypsum hollow slab, steel wire (steel mesh) reinforced cement slab, light concrete slats, composite sandwich light bar and so on. The full name is the construction of the wall with a light strip, as the usual industrial construction, residential construction, public construction of non-load-bearing wall of the main information.

- Q: What is GRC and can I paint it?

- GRC is also called grc components, refers to the fiberglass made of component-type material, grc shape is based on the external wall of the cad drawings to design, generally do not recommend making paint, grc's exterior decoration has its own treatment.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- Fiber mesh, also known as reticular fiber, reticular polypropylene fiber, is a polypropylene as raw material, through a special process from manufacturing. The appearance of a number of fiber monofilament cross-linked from the network structure.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- With my experience I think FRP is better, long life, polyurethane foam and FRP is better, the price comparison is not clear, I only know that FRP: give you a unit price of 1.2 thick, 26 per square, 1.5 Thick ,,, 30 per square ;; Polyurethane foam unit price; 900 per cubic.

Send your message to us

Fabric wrapped fiberglass acoustic wall panel CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches