Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Best Quality Best 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

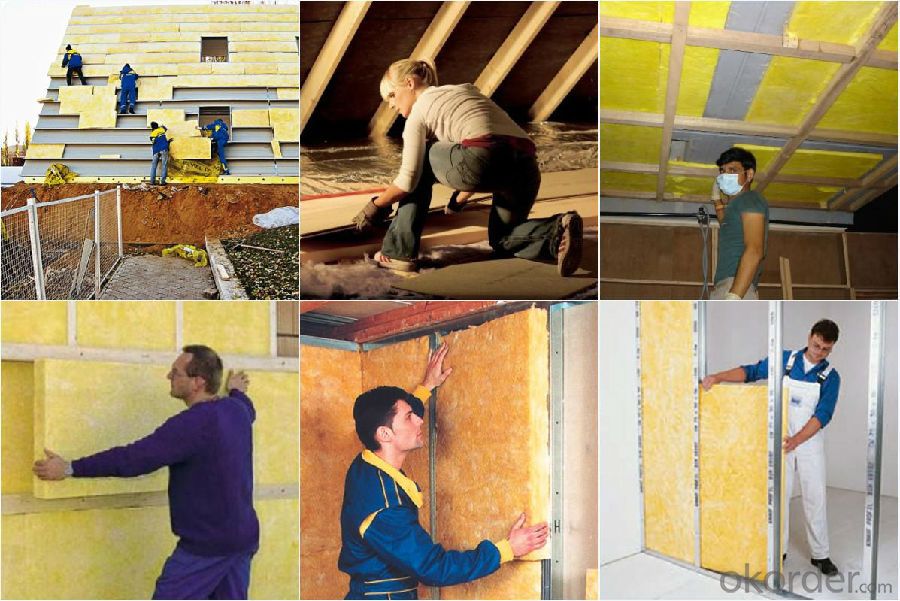

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue resistant to earthquakes?

- No, fiberglass mat tissue is not specifically resistant to earthquakes. Fiberglass mat tissue is a lightweight material commonly used for insulation and reinforcement purposes in construction. While it can provide strength and stability to structures, it does not possess properties that make it inherently earthquake-resistant. To withstand earthquakes, buildings require a combination of design features, materials, and construction techniques that are specifically engineered to withstand seismic forces.

- Q: How is fiberglass mat tissue made?

- The production of fiberglass mat tissue involves a wet-laid process, which encompasses several sequential steps. Initially, glass fibers are generated by melting and extruding glass through tiny apertures, resulting in continuous filaments. These filaments are subsequently coated with a sizing agent, enhancing their manipulability and fortifying the end product. Subsequently, the glass fibers are fragmented into shorter lengths to create a fiber mat. This operation is typically accomplished using either a knife or a rotary chopper. The fragmented fibers are then amassed and fashioned into a thin layer on a moving conveyor belt. Concurrently, a binder solution is formulated by blending a synthetic resin with water. This solution is then sprayed onto the fiber mat, ensuring the fibers become saturated and bonded together. The quantity of binder utilized determines the strength and flexibility of the final product. To guarantee the even distribution of the binder and the proper consolidation of the mat, it is passed through a sequence of rollers. These rollers exert pressure, eliminating excess water, compacting the fibers, and fostering adhesion among them. Once the mat is consolidated and attains the desired thickness, it undergoes a drying process, either in an oven or via hot air currents. This eliminates any remaining moisture and solidifies the binder, transforming it into a solid resin. Following the drying stage, the fiberglass mat tissue is wound onto rolls for storage or further processing. Due to its exceptional strength, resistance to corrosion, and thermal insulation properties, it serves as a reinforcement material in diverse industries such as construction, automotive, and aerospace.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Yes, fiberglass mat tissue can be used for insulating radiant floors. It is an effective insulation material that helps to minimize heat loss and improve energy efficiency in radiant floor heating systems.

- Q: What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue is subject to variation based on factors like the material's specific composition and thickness. As a general rule, fiberglass mat tissue tends to exhibit a relatively low moisture vapor transmission rate. Its ability to facilitate the passage of moisture vapor is comparatively limited. Consequently, this attribute renders it suitable for applications where moisture resistance is sought, such as in insulation or construction materials. However, it is crucial to acknowledge that the moisture vapor transmission rate of fiberglass mat tissue can be additionally impacted by other variables, including the existence of coatings or laminations. These additional elements have the potential to enhance or restrict its moisture vapor transmission properties.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. It is a commonly used material for reinforcing and repairing fiberglass surfaces, including shower stalls.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The different thickness tolerances for fiberglass mat tissue can vary depending on the specific product and manufacturer. However, common thickness tolerances range from +/- 0.001 inches to +/- 0.005 inches.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Yes, fiberglass mat tissue can be used for automotive parts. It is commonly used in the automotive industry for various applications such as reinforcing panels, creating structural components, and improving overall strength and durability of automotive parts.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. Fiberglass mat tissue is a lightweight material that is commonly used for sound absorption and insulation purposes. It has excellent sound-absorbing properties and can effectively reduce noise levels in various applications, including acoustic panels. It is often used as the core material in acoustic panels to enhance their sound-absorbing capabilities. Additionally, fiberglass mat tissue is easy to work with, making it a popular choice for DIY acoustic panel projects. However, it is important to note that the effectiveness of acoustic panels also depends on other factors such as panel design, thickness, density, and installation method. Therefore, it is recommended to consult with experts or conduct thorough research to ensure that fiberglass mat tissue is the appropriate material for your specific acoustic panel needs.

- Q: How does the width of fiberglass mat tissue affect its installation?

- The width of fiberglass mat tissue affects its installation by determining the amount of coverage it provides per roll. A wider mat tissue will cover a larger area with each roll, reducing the number of rolls needed for installation. This can save time and effort during the installation process. Additionally, a wider width may also provide better overall strength and stability to the installed fiberglass mat tissue.

- Q: How does fiberglass mat tissue contribute to the strength and durability of composite materials?

- The strength and durability of composite materials are greatly enhanced by fiberglass mat tissue. To begin with, the mat tissue acts as a reinforcement element, providing added strength and rigidity to the composite structure. The fibers in the mat tissue are usually made of glass, which possesses high tensile strength and stiffness. These fibers are arranged randomly, forming a three-dimensional network that evenly distributes stress throughout the composite material. This network of fibers helps to resist cracks and fractures, thus increasing the overall strength of the composite. Additionally, the mat tissue serves as a protective barrier against delamination, a common problem in composite materials. Delamination refers to the separation of layers within the composite, which can weaken its structural integrity. By bonding the layers together and improving their adhesion, the fiberglass mat tissue prevents delamination. This enhanced adhesion reduces the chances of interface failure and improves the overall durability of the composite material. Moreover, fiberglass mat tissue contributes to the improved impact resistance of composite materials. The random fiber orientation within the mat tissue creates a crisscross pattern that enhances the composite's ability to absorb and distribute impact energy. This characteristic makes the material less susceptible to damage from external forces, such as impacts, vibrations, or mechanical stress. In conclusion, fiberglass mat tissue plays a vital role in strengthening and enhancing the durability of composite materials. Its reinforcement capabilities, delamination prevention, and improved impact resistance make it an essential component in various industries, including automotive, aerospace, construction, and marine, where the demand for strong and durable materials is critical.

Send your message to us

Fiberglass Mat Tissue Glass Wool Insulation Blanket CNBM Best Quality Best 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords