Glass wool insulation with one side FSK aluminium foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

The glass wool product can be made into glass wool board, glass wool blanket, glass wool pipe, and it is widely used for insulation, sound proofing and heat preservation.

We have CE, A1, AS/NZS4859.1, SAI-GLOBAL, MSDS, ISO9001 Certificates.

We will offer Excellent quality, competitive price for customers.

For increasing loading quantity and reducing cost of transportation, all exported glass wool blanket would be packed vacuum.

Glass wool is bright yellow in colour, tasteless or feint in smell, and no-injurant to human body, it's excellent for heat insulation.

2.Main features of Glass Wool Blanket:

1.Excellent thermal, acoustical properties

2.Light weight and easy to fabricate on job site

3.Non-combustible and fire-retardant

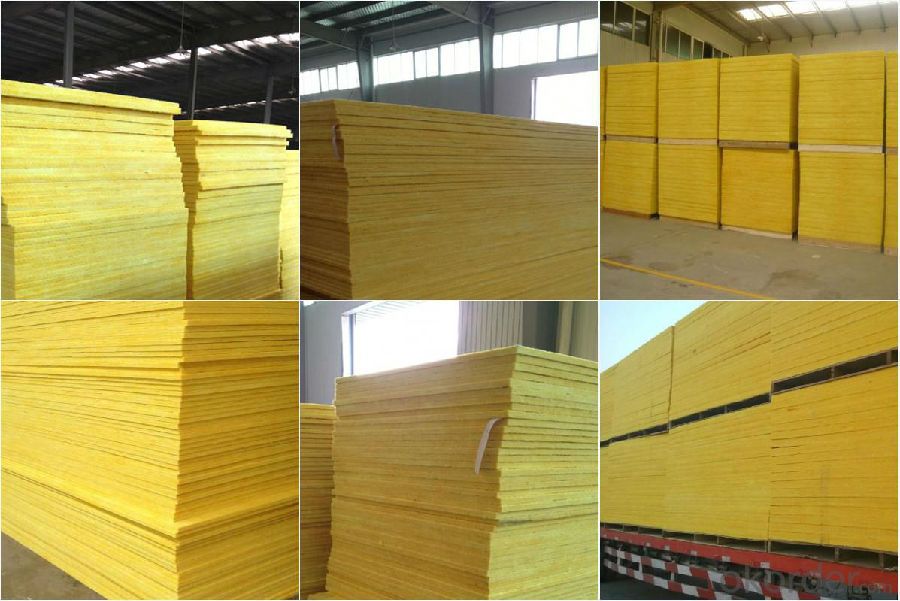

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures due to its inherent heat resistance properties. The mat is typically made from glass fibers that are woven together, creating a strong and durable material. These glass fibers have a high melting point, allowing the fiberglass mat tissue to withstand elevated temperatures without deforming or losing its structural integrity. When exposed to high temperatures, fiberglass mat tissue does not shrink, warp, or become brittle like other materials might. It retains its dimensional stability and mechanical strength, making it suitable for various applications in industries such as automotive, aerospace, construction, and insulation. Additionally, fiberglass mat tissue acts as a thermal insulator, offering protection against heat transfer. It can effectively resist heat conduction and radiation, helping to maintain the desired temperature in a given environment or prevent heat damage to surrounding components. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not burn or produce toxic gases when exposed to fire. This makes it a reliable choice for applications that require fire resistance, such as fireproofing insulation or protective barriers. In summary, fiberglass mat tissue performs exceptionally well in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature make it an excellent material for use in demanding environments where elevated temperatures are present.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. Fiberglass mat tissue is a versatile material that is commonly used for reinforcing and repairing fiberglass structures, including shower stalls. It is designed to provide strength and durability to the repaired area, ensuring a long-lasting and reliable fix. When used in combination with a suitable fiberglass resin, fiberglass mat tissue can effectively repair cracks, holes, and other damages in fiberglass shower stalls. However, it is important to carefully follow the manufacturer's instructions and guidelines for proper application and curing to ensure the best results.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Yes, fiberglass mat tissue is suitable for insulation in laboratories. It offers excellent thermal insulation properties, is resistant to high temperatures, and provides effective sound insulation. Additionally, it is non-combustible and chemically inert, making it ideal for laboratory environments where safety and performance are crucial.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Indeed, fiberglass mat tissue proves to be a valuable asset when it comes to restoring fiberglass jet skis. This material is frequently employed in fiberglass repairs due to its ability to fortify and reinforce afflicted regions. Its versatility allows for its use in a multitude of fiberglass repair scenarios, such as rectifying cracks or punctures found in jet skis. When skillfully applied, fiberglass mat tissue effectively reestablishes the jet ski's structural soundness, guaranteeing a resilient and enduring mending.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. It is commonly used as a reinforcement material for various components such as body panels, bumpers, and interior parts. It provides strength, durability, and excellent resistance to corrosion and heat, making it an ideal choice for automotive applications.

- Q: Is fiberglass mat tissue resistant to acids?

- Yes, fiberglass mat tissue is generally resistant to acids.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue plays a crucial role in determining its performance. Thicker fiberglass mat tissues generally provide better strength and durability compared to thinner ones. A thicker mat tissue allows for a higher resin-to-glass ratio, resulting in improved stiffness and toughness. This increased resin content enhances the overall structural integrity and mechanical properties of the fiberglass mat tissue. It also helps to minimize the risk of delamination and improves resistance to impact and fatigue. Moreover, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a higher density of fibers, which enhances the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to note that the specific application and requirements should be considered when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more expensive. Therefore, a balance must be struck between the desired performance characteristics and the practical considerations of weight, cost, and ease of installation.

- Q: How is fiberglass mat tissue used in the automotive industry?

- The automotive industry relies heavily on fiberglass mat tissue for various purposes. This versatile material offers numerous advantages, making it an ideal choice for multiple applications. Reinforcing composite materials is one of the primary uses of fiberglass mat tissue in the automotive industry. It is commonly employed as a reinforcement layer during the production of car panels, hoods, roofs, and doors. By enhancing the structural integrity of these components, the fiberglass mat tissue makes them more durable and resistant to impact and external forces. This reinforcement property contributes to the overall safety of the vehicle. Furthermore, fiberglass mat tissue is also utilized for sound insulation in the automotive industry. This material possesses excellent sound absorption properties, effectively reducing noise and vibrations within the vehicle. By incorporating fiberglass mat tissue in areas like the floor, doors, and roof, automakers can significantly improve the overall acoustic comfort of the vehicle, providing a quieter and more enjoyable driving experience. Moreover, fiberglass mat tissue finds application in thermal insulation within the automotive industry. Acting as a barrier against heat transfer, this material helps regulate the temperature inside the vehicle. By incorporating fiberglass mat tissue in areas such as the engine compartment, exhaust system, and undercarriage, automakers can insulate the vehicle from excessive heat, preventing overheating and ensuring optimal performance. In conclusion, fiberglass mat tissue is extensively used in the automotive industry for reinforcement, sound insulation, and thermal insulation purposes. Its versatility makes it an indispensable material in vehicle manufacturing, contributing to improved safety, comfort, and performance.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation with their own unique characteristics and benefits. Fiberglass mat tissue is a lightweight and flexible material made from spun glass fibers that are arranged into a mat. It is commonly used in the construction industry for thermal and acoustic insulation purposes. Fiberglass mat tissue is relatively easy to install and provides good thermal resistance, helping to regulate temperature and reduce energy loss. However, it may not be as effective in sealing air leaks or filling gaps compared to spray foam insulation. On the other hand, spray foam insulation is a liquid mixture that expands into a foam after being sprayed. It fills gaps and crevices, creating an airtight seal that helps to prevent air leakage and reduce energy consumption. Spray foam insulation can also provide a higher R-value (a measure of thermal resistance) compared to fiberglass mat tissue, making it more efficient in terms of insulation performance. However, the installation process for spray foam insulation can be more complex and may require professional assistance. In summary, fiberglass mat tissue is a cost-effective and easy-to-install insulation option that offers good thermal resistance but may be less effective in sealing air leaks. Spray foam insulation, on the other hand, provides superior insulation performance and air sealing capabilities, but may require professional installation and can be more expensive. Ultimately, the choice between the two will depend on factors such as budget, specific insulation needs, and the desired level of air sealing.

Send your message to us

Glass wool insulation with one side FSK aluminium foil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords